Anti-breaking chain joint structure

A joint structure and connection structure technology, applied in the direction of belts/chains/gears, chain elements, mechanical equipment, etc., can solve problems such as the failure of the connection between the chain and the target component, affecting the normal operation of the equipment, and the separation of the chain and the joint, so as to ensure the use , Protecting safety and avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

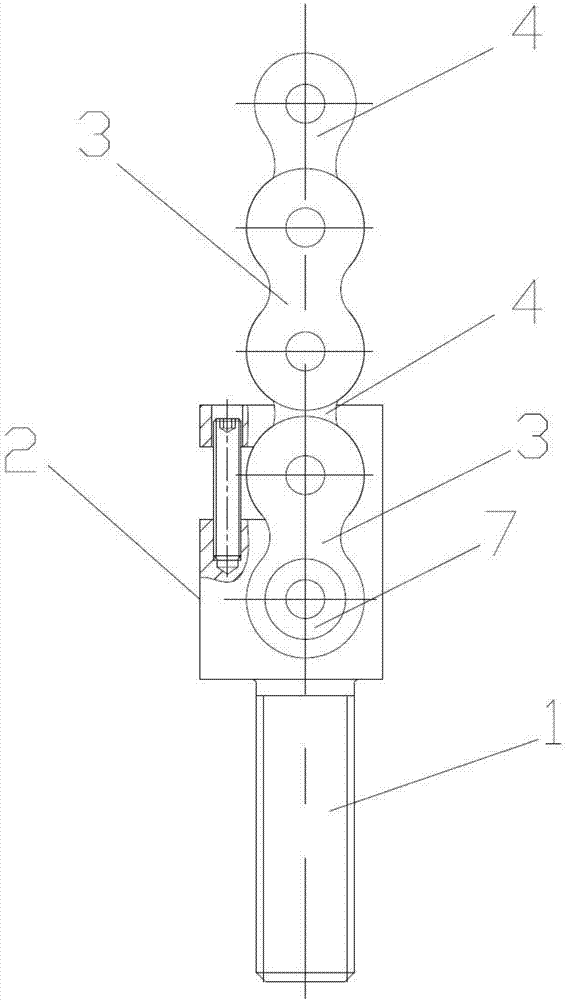

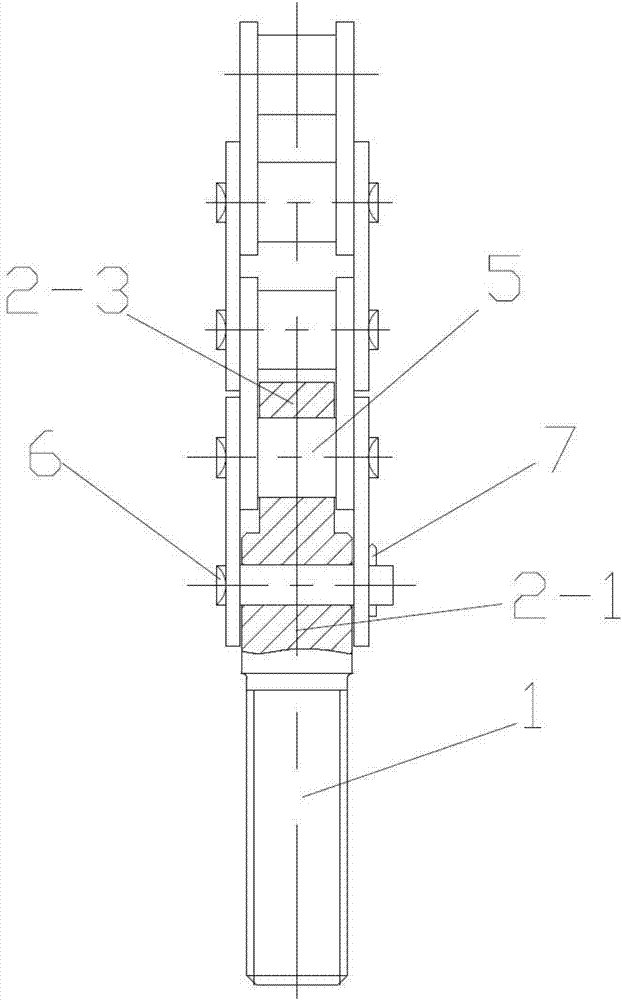

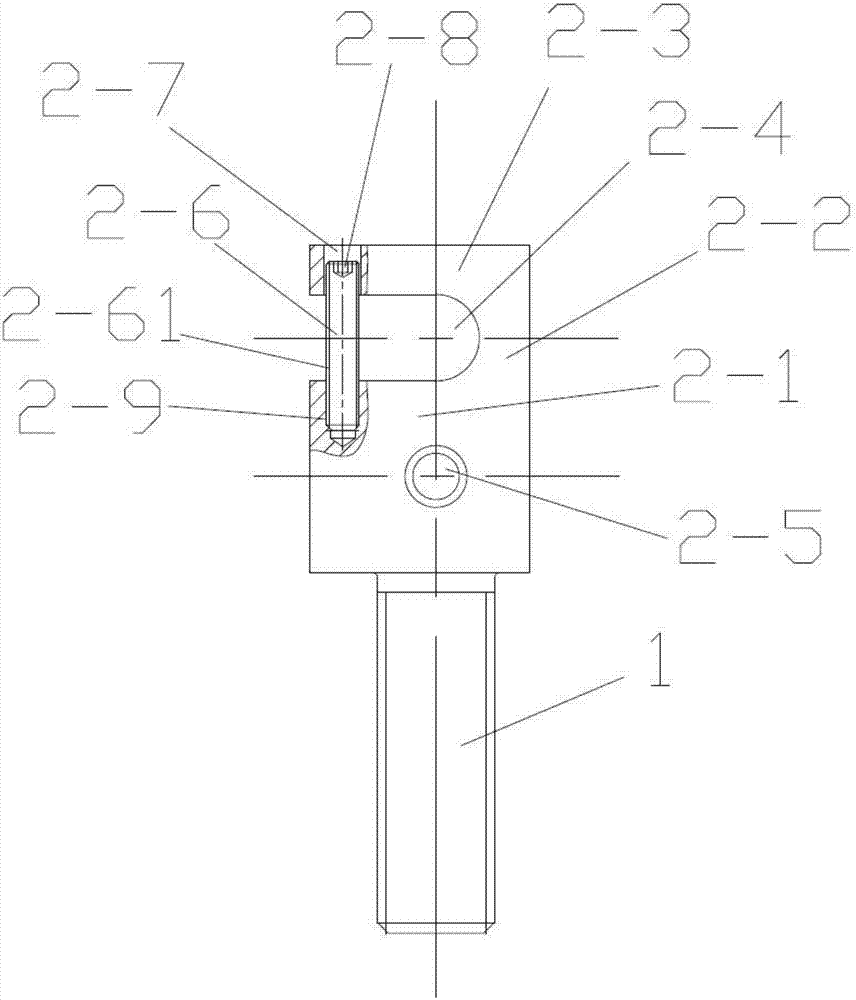

[0031] see Figure 1-Figure 3 The anti-break chain joint structure of this embodiment includes a joint 2, a pin shaft 6 and a snap spring 7, and the first connection end 2-1 of the joint 2 is connected to the two chain plates at the end of the chain through the pin shaft 7. The circlip 7 is arranged at the end of the pin shaft 6; the chain is formed by sequentially connecting the inner chain plate 4 and the outer chain plate 3 through the sleeve roller 5, wherein the first connecting end 2-1 of the joint 2 The two outer chain plates 3 at the end of the chain are connected by a pin 6; the first connecting end 2-1 of the joint 2 is provided with a pin hole 2-5 for passing the pin 6. The first connecting end 2-1 of the joint 2 is provided with a safety lock hole 2-4 above the pin shaft 6, and the sleeve roller 5 located above the pin shaft 6 in the chain passes through the safety lock hole 2 -4.

[0032] see Figure 1-Figure 3 , the outer side of the safety lock hole 2-4 has a...

Embodiment 2

[0039] The difference between this embodiment and embodiment 1 is that in this embodiment:

[0040] see Figure 4-Figure 8 , the second vertical connecting section is a connecting plate 2-10, and the detachable connecting structure includes an upper connecting screw 2-102 connecting the upper end of the connecting plate 2-10 to the transverse connecting section 2-3 and connecting The lower end of the connecting plate 2-10 is connected to the lower connecting screw 2-103 on the first connecting end 2-1 of the joint 2. By adopting the second vertical connecting section with the above-mentioned structure, the connection is more firm, which can effectively prevent the second vertical connecting section from falling off.

[0041] see Figure 4-Figure 8 , the connecting plate 2-10 includes a main body 2-101, the main body 2-101 is provided with a first semicircular groove 2-104 on the side facing the first vertical connecting section 2-2, the first vertical The connecting section...

Embodiment 3

[0044] The difference between this embodiment and embodiment 1 is that in this embodiment:

[0045] see Figure 9-Figure 11 , there are two safety lock holes, which extend along the length direction of the chain and are respectively the first safety lock hole 2-14 and the second safety lock hole 2-16, wherein the first safety lock hole 2-14 is located at Above the second safety lock hole 2-16; the first safety lock hole 2-14 is set outside the first sleeve roller 5-1, and the second safety lock hole 2-16 is set on the second Outside the sleeve roller 5-2; there are also two transverse connecting sections, which are the first transverse connecting section 2-13 above the first safety lock hole 2-14 and the second safety lock hole 2-16. The upper second transverse connecting segment 2-15. With such a design, when the pin shaft 6 is disengaged, more sleeve rollers can cooperate with the safety keyhole to share the load, and the safety protection effect is better.

[0046] see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com