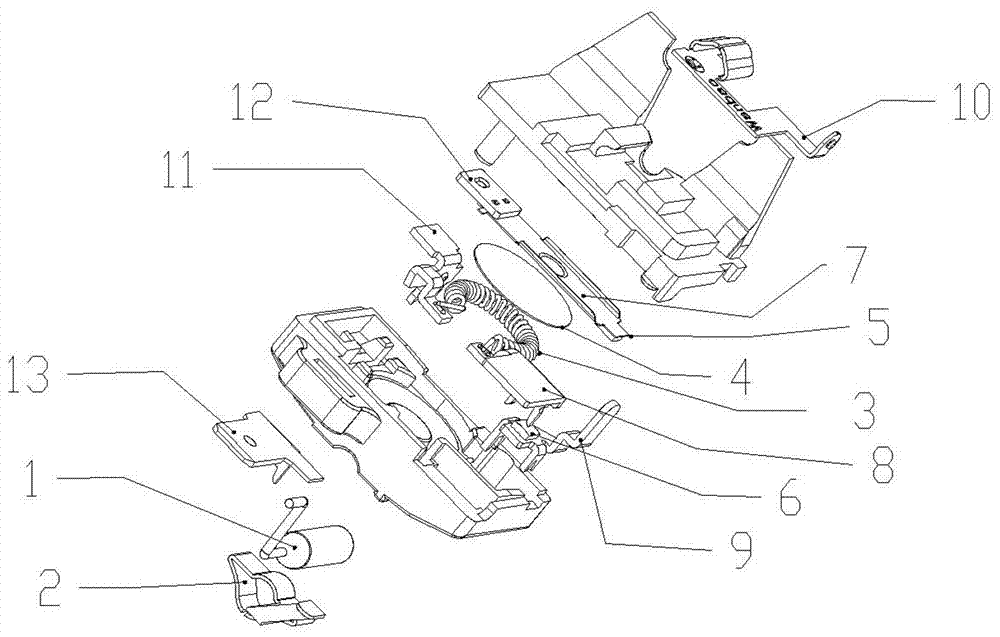

Current overload protector structure

An overload protector and current overload technology, applied in the direction of protection switch operation/release mechanism, etc., can solve problems such as contact welding, actual current instability, and potential safety hazards, simplify maintenance steps, save labor costs, The effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

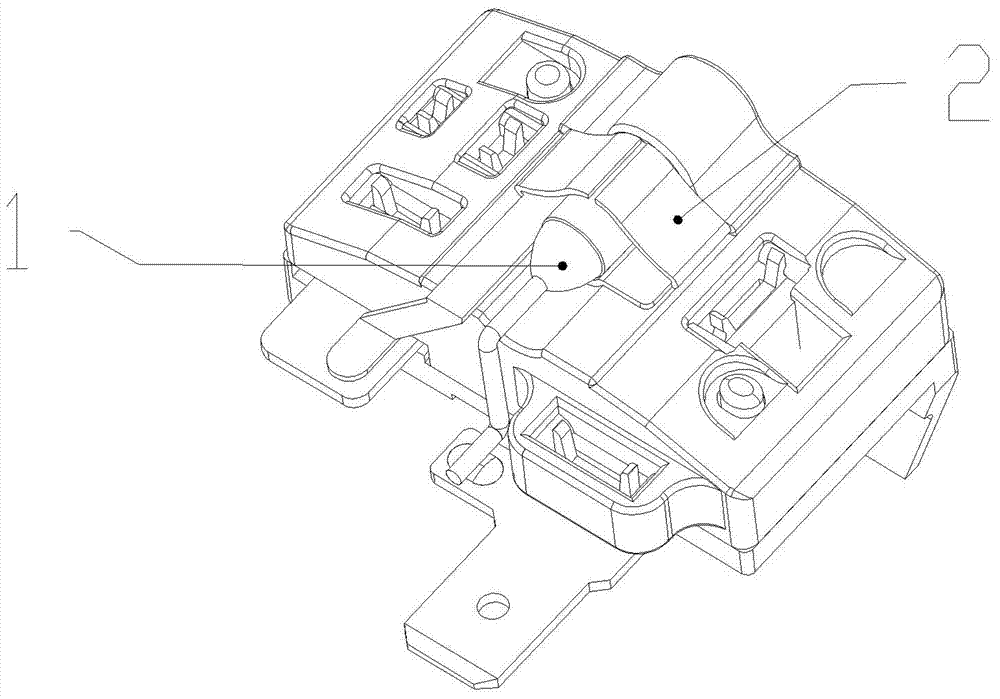

[0011] Such as figure 1 , figure 2 As shown, the structure of the overload protector of the present invention includes a base, a cover plate, a terminal 13, a thermal fuse 1, a clip 2, a heating wire 3, a static foot 801, a static foot 803, a static foot 804 pad, and a moving reed 7. Moving contact 5 and static contact 6, pin 10. Moving reed 7 is a strip metal sheet, its right end lower part is provided with movable contact 5, left end upper part is provided with liner 12 and is welded with it, and left end lower part is welded with the upper surface of the protrusion of block static foot 801. The static foot 801 also has a depression, which corresponds to the depression of the static foot 804 provided on the right side. The two ends of the heating wire 3 are respectively connected to the depressions of the static feet on both sides, and a bimetal is arranged above the heating wire. slice 4. The static pin 803 is arranged slightly higher on the right side of the static pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com