Vertical conductor bonded quick tensioner fitting support insulator in use

A technology supporting insulators and vertical conductors, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as short circuit and grounding, achieve installation process specifications, and reduce friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

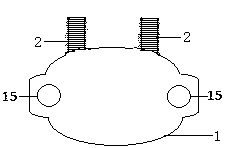

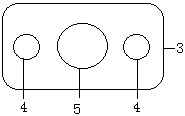

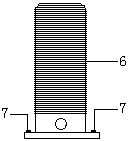

[0009] figure 1 A connecting bolt 2 is set on the top of the reinforcement connecting plate 1, and a connecting bolt 2 is set on the top of the connecting bolt 2 figure 2 Adjust the bolt rod crimping plate 3, set the bolt sliding hole 4 at both sides of the adjusting bolt rod crimping plate 3, set the adjusting bolt rod through the hole 5 at the middle position, and set the adjusting bolt rod through the hole 5 image 3 Adjust the bolt rod 6, adjust the bolt cap of the bolt rod 6 to set the sliding bean 7, adjust the bolt rod 6 to set the Figure 4 Tension-resistant head 8, the two sides of the upper part of the tension-resistant head 8 are provided with bolt holes 9, and the upper part of the bolt hole 9 is arranged Figure 5 Tension frame 10, the two lower ends of tension frame 10 are provided with pressing bolt sliding holes 11, the two sides of the middle part are provided with pulley rotating shaft holes 12, and the inside of pulley rotating shaft holes 12 are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com