Installation method of circulating water pump of seawater direct cooling unit

A technology of circulating water pump and installation method, which is applied to parts, pumps, pump components, etc. of pumping devices used for elastic fluids. Raw material costs and processing costs, reduced workload, accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

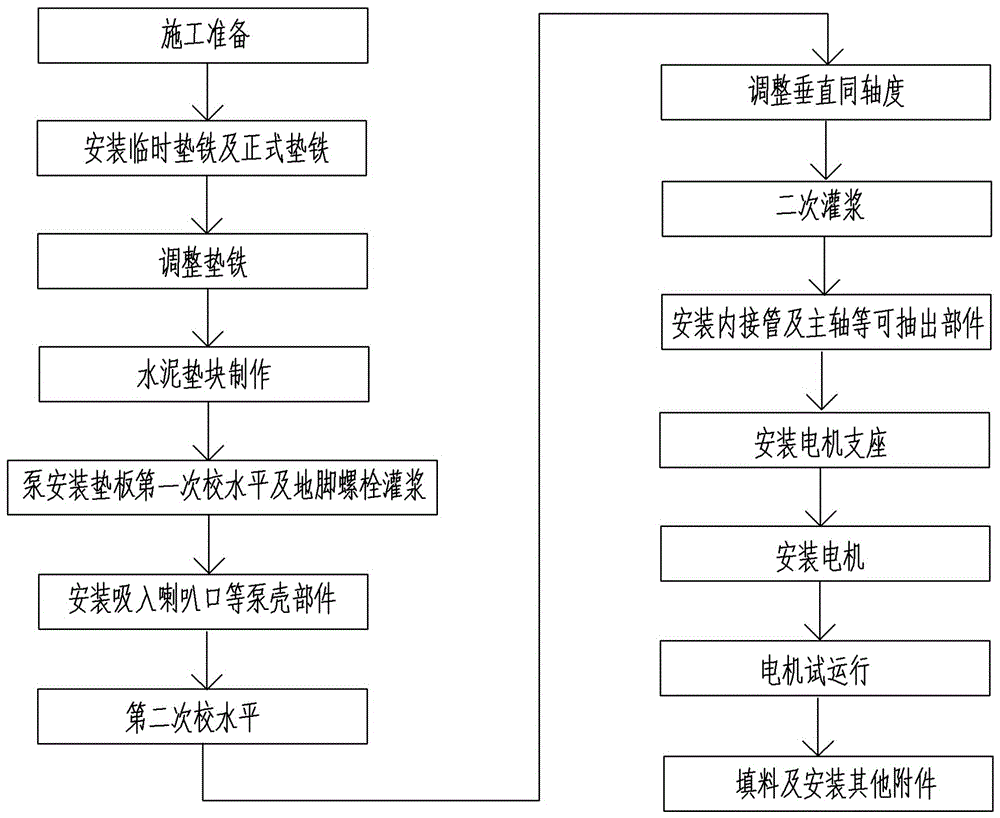

[0035] Embodiment: A method for installing a circulating water pump of a seawater direct cooling unit, comprising the following steps:

[0036] (1) Construction preparation: preparation of basic materials and checking whether the infrastructure is installed in place.

[0037] (2) Install temporary shims and formal shims: find out the position of the shims according to the construction drawings, then chisel out the rough surface on the surface of the positions, determine the actual elevation according to the construction drawings, use temporary shims to support the equipment, and then level the equipment Adjustment, after the equipment is adjusted, install formal shims on both sides of the anchor bolt holes and the load-bearing places of the base.

[0038] In order to improve the efficiency and overcome the common problem of poor contact surface between the pad iron and the foundation, concrete grinding discs are often used to repair and grind the cement foundation where the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com