Integral mounting structure of built-in mutual inductor for gas-insulated switchgear

A technology of overall installation and transformer, which is applied to the installation/support/suspension of inductors, transformers/reactors, and switchgear settings, etc., to simplify the construction steps, reduce the difficulty of construction and installation, and save installation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

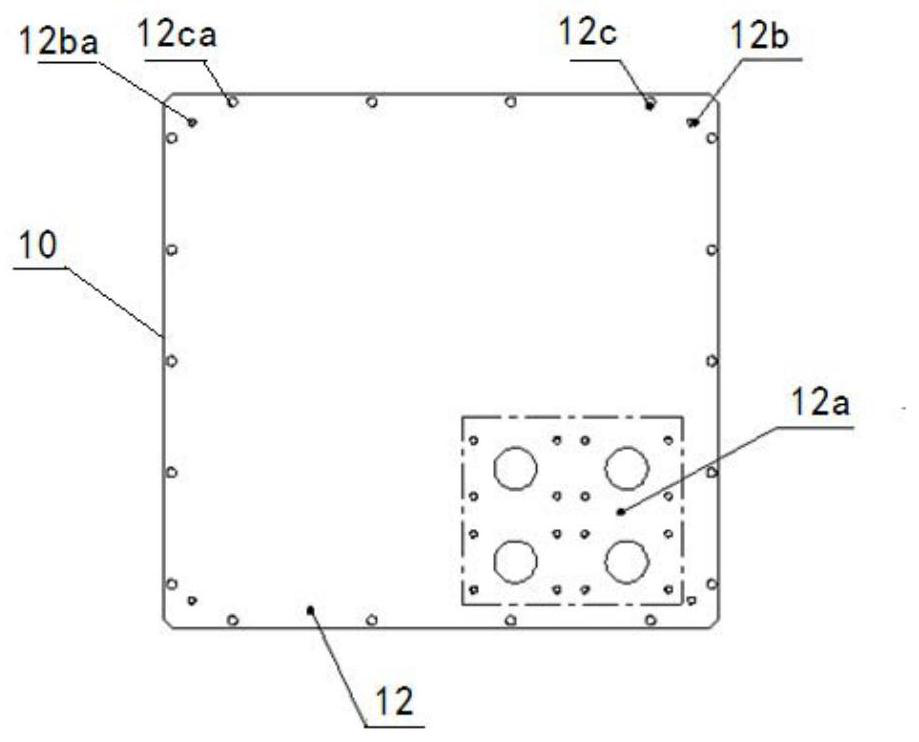

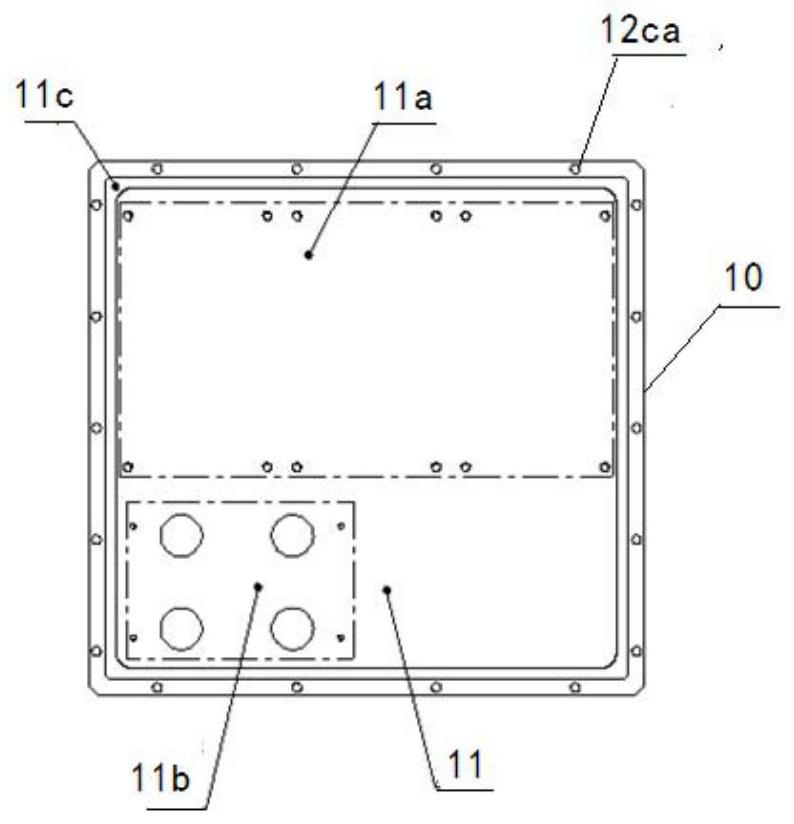

[0028] See attached Figure 1 to Figure 8 , shown in the figure is an embodiment of the overall installation structure of the built-in transformer for the inflatable cabinet. The overall installation structure of the built-in transformer for the inflatable cabinet in this embodiment includes three metal flange mounting plates 10, A, B, and C. The built-in transformer 20, the secondary sealing connector 30, the secondary metal baffle plate 70, the lifting ring 40, the flange plate sealing ring 50, the gas box 60 of the gas charging cabinet, and some fixing bolts of various specifications are used for the gas filling cabinet.

[0029] Such as Figure 1 to Figure 3 As shown, the metal flange mounting plate 10 includes an inner mounting surface 11 and an outer mounting surface 12 . The inner mounting surface 11 includes: a three-phase built-in tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com