Developing box

A developing cartridge and developer technology, which is applied in the field of developing cartridges, can solve the problems such as high requirements on the assembly progress of the rotating shaft and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

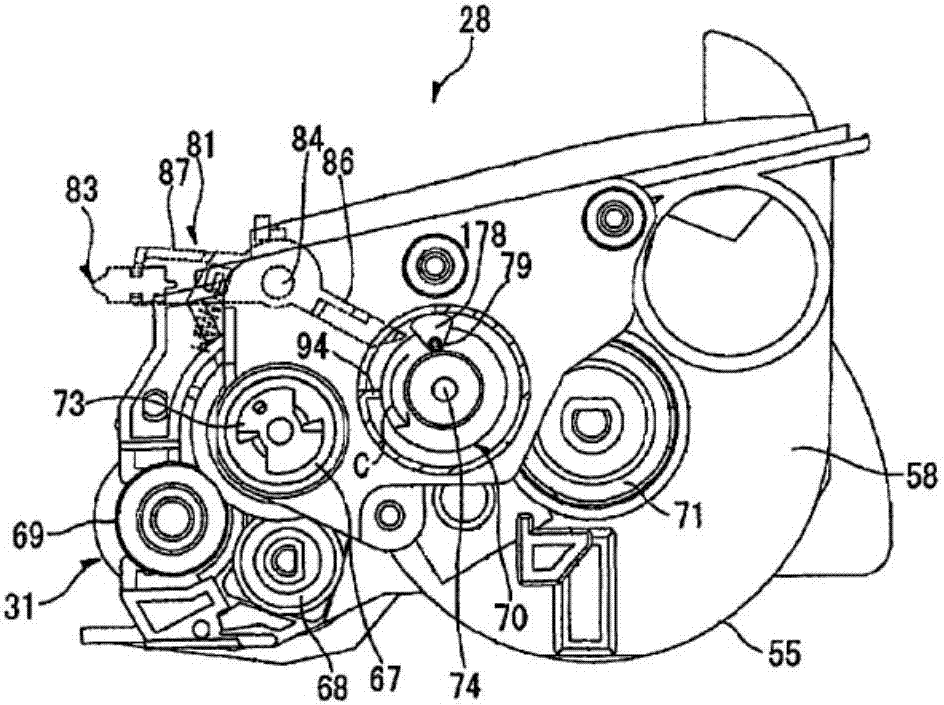

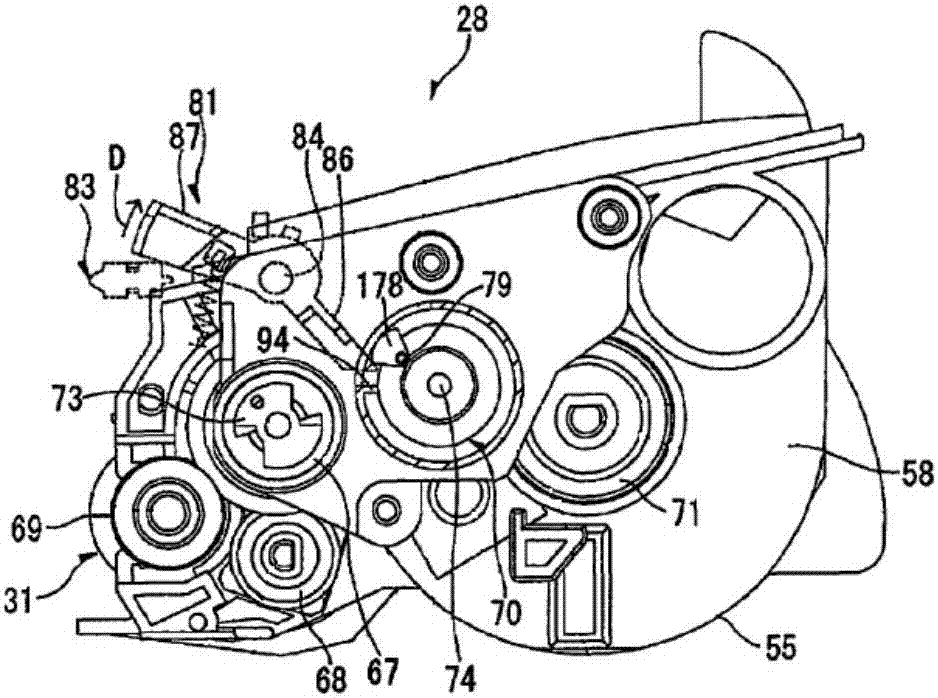

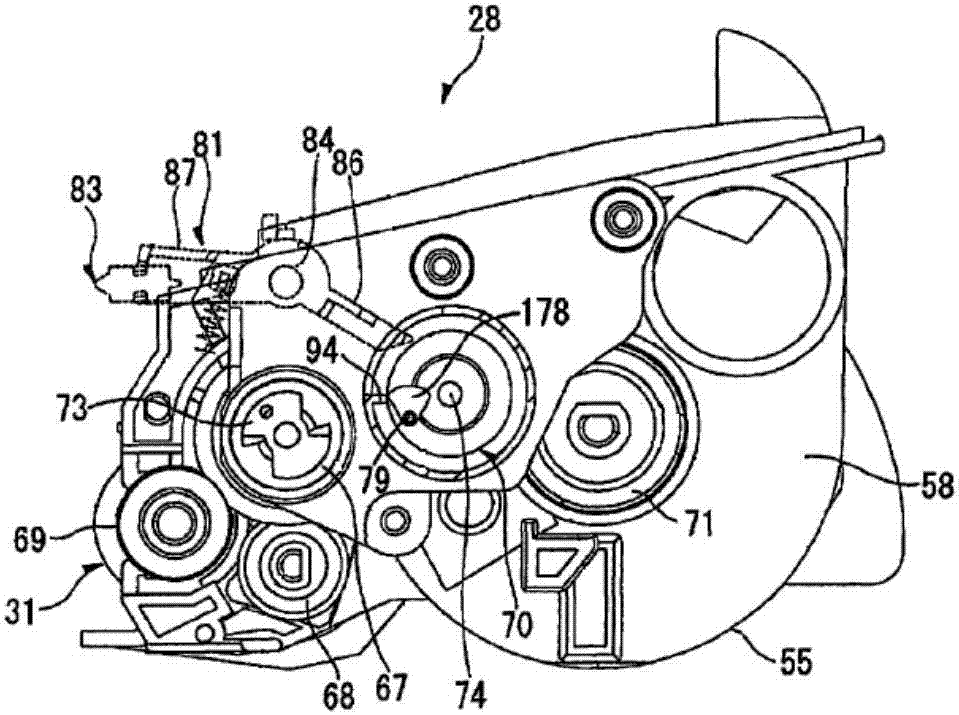

[0035] In this embodiment, a developing cartridge is provided. The developing cartridge can be applied to commonly used electrophotographic imaging devices such as printers, copiers and facsimile machines, and the overall structure of the developing cartridge is consistent with Figure 1 to Figure 3 The overall structure of the developing cartridge in is similar, so if there is no special instruction, the overall structure of the developing cartridge in this embodiment is the same as figure 1 the same or similar in . The developing cartridge of this embodiment specifically includes a powder bin for accommodating the developer, and also includes a counting mechanism and a transmission gear for transmitting power to the counting mechanism. The counting mechanism includes a first rotating member and a second rotating member.

[0036] Wherein, the transmission gear can at least mesh with one of the first rotating member and the second rotating member to transmit power to the count...

Embodiment 2

[0061] On the basis of the first embodiment above, the first rotating member can also be configured as a full-toothed gear structure, and the first rotating member and the second rotating member are not coaxially connected, but meshed with each other. Figure 7a It is a schematic diagram of the structure of the counting mechanism in the developing cartridge in the initial position provided by the second embodiment of the present invention. Figure 7b It is a schematic diagram of the structure of the counting mechanism in the developing cartridge in the final position provided by the second embodiment of the present invention. Such as Figure 7a and Figure 7b As shown, in this embodiment, the first rotating member 111 can be set as a full-toothed gear, and the second rotating member 112 can be a tooth-less gear, and the first rotating member 111 and the second rotating member 112 mesh, and the second rotating member 112 and The transmission gear 25 is engaged.

[0062] Spec...

Embodiment 3

[0072] In addition, an additional rotating member may also be provided to play a role of connection and transmission between the first rotating member and the second rotating member. Figure 8a It is a structural schematic diagram of the counting mechanism in the initial position of the developing cartridge provided by Embodiment 3 of the present invention. Figure 8b It is a structural schematic diagram of the counting mechanism in the developing cartridge provided by Embodiment 3 of the present invention at the final position. Such as Figure 8a and Figure 8b As shown, in this embodiment, in addition to the first rotating member 134 and the third rotating member 131, the counting mechanism also includes a second rotating member 132, the first rotating member 134 is a full tooth gear, the third rotating member 131 and the second rotating member Parts 132 are toothless gears, and the third rotating part 131 and the second rotating part 132 rotate coaxially, and can form a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com