An automatic palletizing device and automatic palletizing control method for vertical parts of wall-mounted boards

The technology of a palletizing device and a control method, which is applied in the direction of unstacking of objects, stacking of objects, conveyor objects, etc., can solve problems such as high labor intensity, reduce labor costs, reduce labor intensity, and save labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

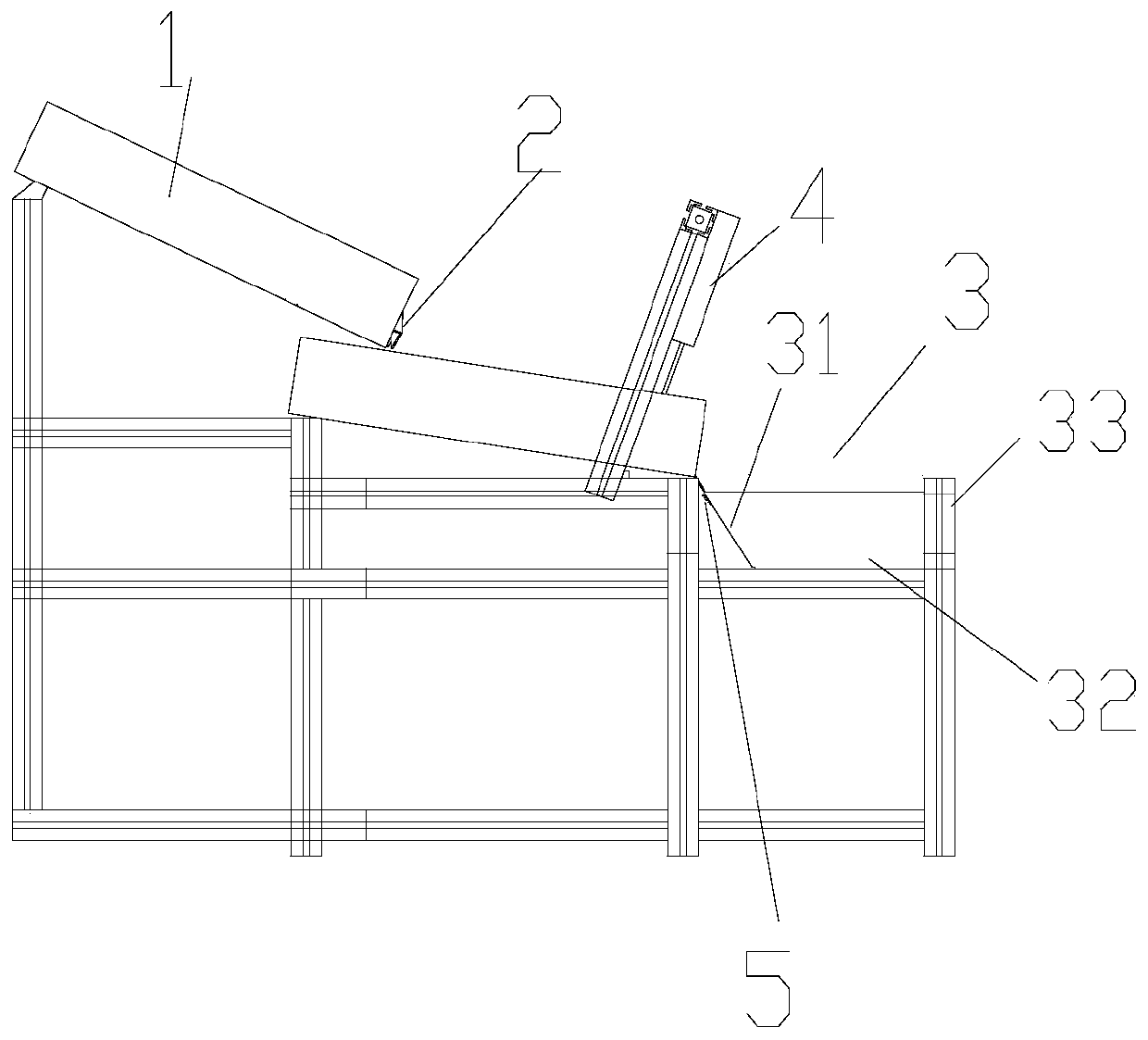

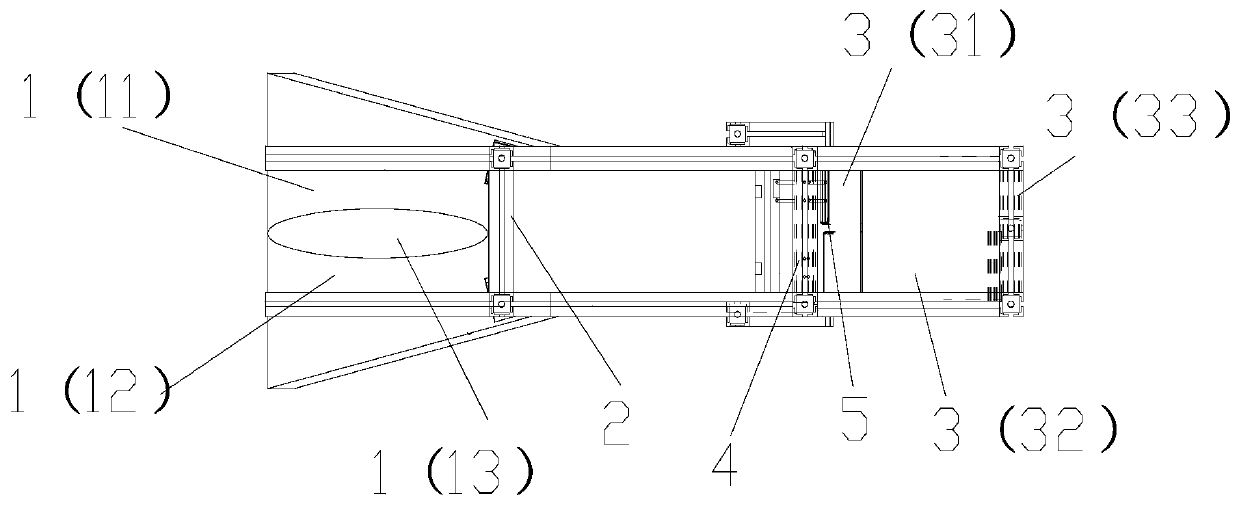

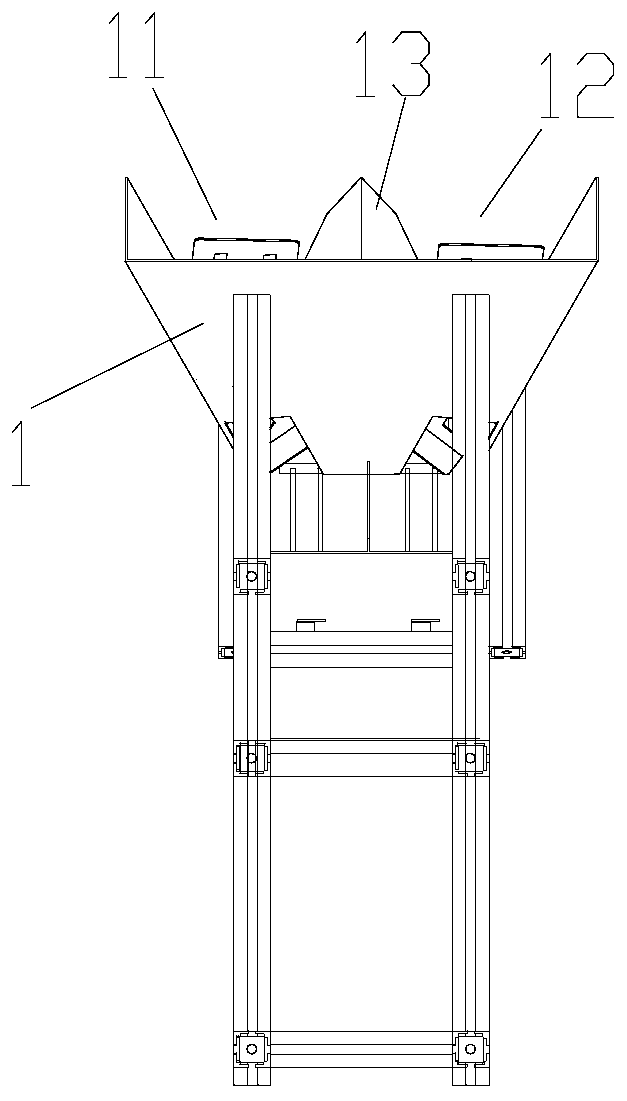

[0049] Such as Figure 1-3 As shown, the present invention provides an automatic palletizing device for vertical parts of wall-mounted boards, which includes:

[0050] The material distribution unit 1 is used to divide the material channel into two side-by-side material channels, so that the side-by-side parts punched out by the press machine enter the two material channels respectively;

[0051] The turning unit 2 is used to receive the parts sent out from the dispensing unit 1 and turn the parts flowing through the place up and down so that the original bottom faces upward;

[0052] The palletizing unit 3 is used to receive the parts conveyed by the turning unit 2, and to stack the two paths of parts separately.

[0053] Before the present invention: After the vertical parts of the wall hanging board are stamped by the press, they are dropped into the plastic box through the belt, and need to be manually stacked and placed in the constant volume box. Damage and deformation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com