Tea leaf pressing bar structure for post-processing tea leaves

A technology of layering and tea leaves, which is applied in the field of layering bar structure technology and structure, can solve the problems of waste and loss of tea leaves, unsmooth rotation and sliding of layering bars, and large resistance, etc., to reduce labor intensity, improve fluency, and be convenient, flexible and labor-saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, embodiments of the present invention will be described in detail, examples of which are shown in the accompanying drawings and the following description. While the invention will be described in conjunction with exemplary embodiments, it will be understood that the description is not intended to limit the invention to the exemplary embodiments. On the contrary, the invention is to cover not only the exemplary embodiment, but also various alternatives, modifications, equivalents and other embodiments, which may be included within the spirit and scope of the invention as defined by the appended claims Inside.

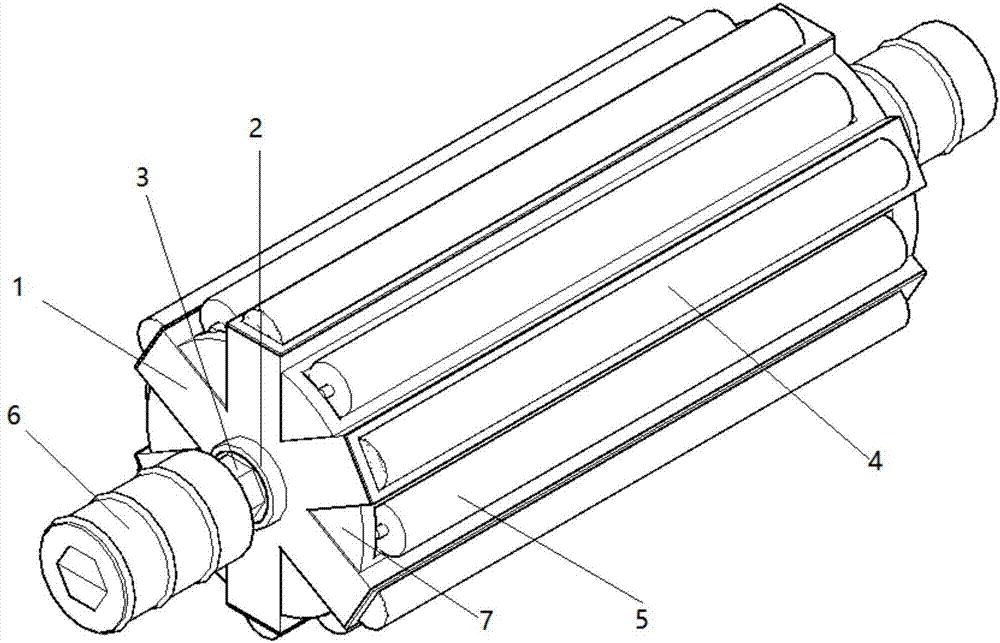

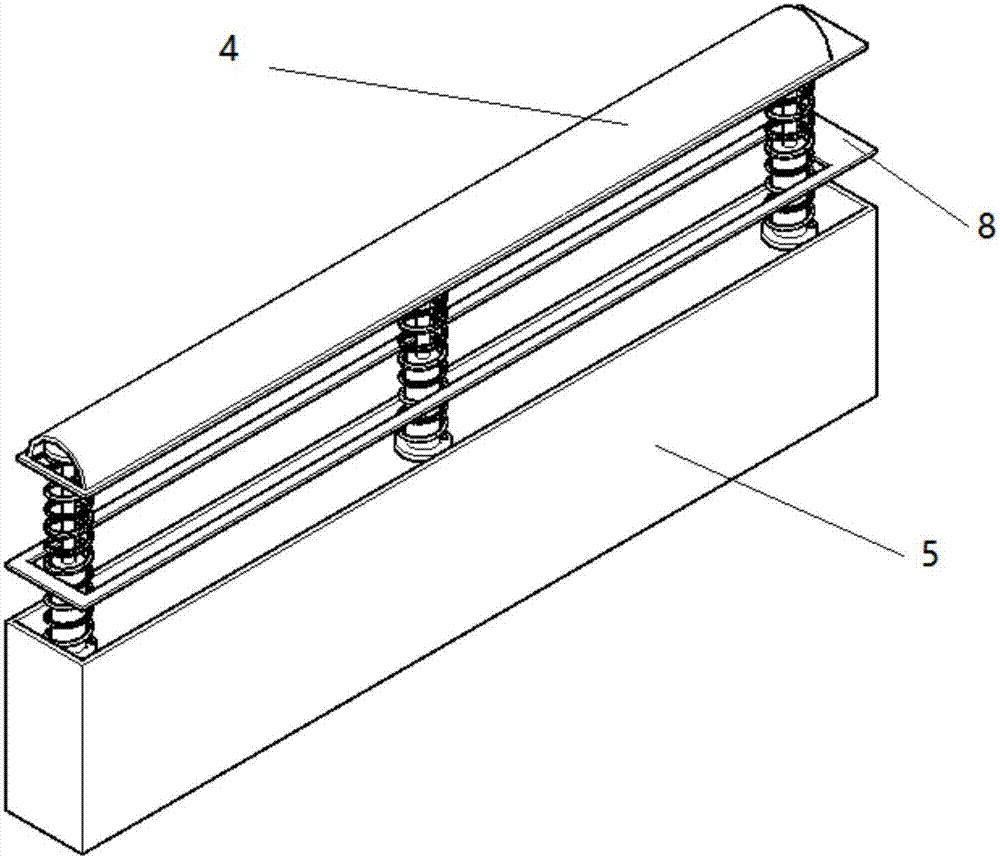

[0019] see figure 1 to attach figure 2 , a tea bar structure for post-processing of tea leaves, comprising:

[0020] Bead bar support frame 1, bearing 2, central fixed shaft 3, arch buffer plate 4, roller 5, handle 6, fan-shaped fixing groove 7 and limit top plate 8;

[0021] The bead support frame 1 is composed of six heel frames connected and fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap