Two-for-one twister capable of detecting spindle speed and judging yarn state and working method thereof

A technology of double twister and spindle speed, applied in spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve the problems of low yarn quality, low work efficiency, undetectable spindle speed, etc. The effect of controllable differences, high work efficiency and high yarn quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

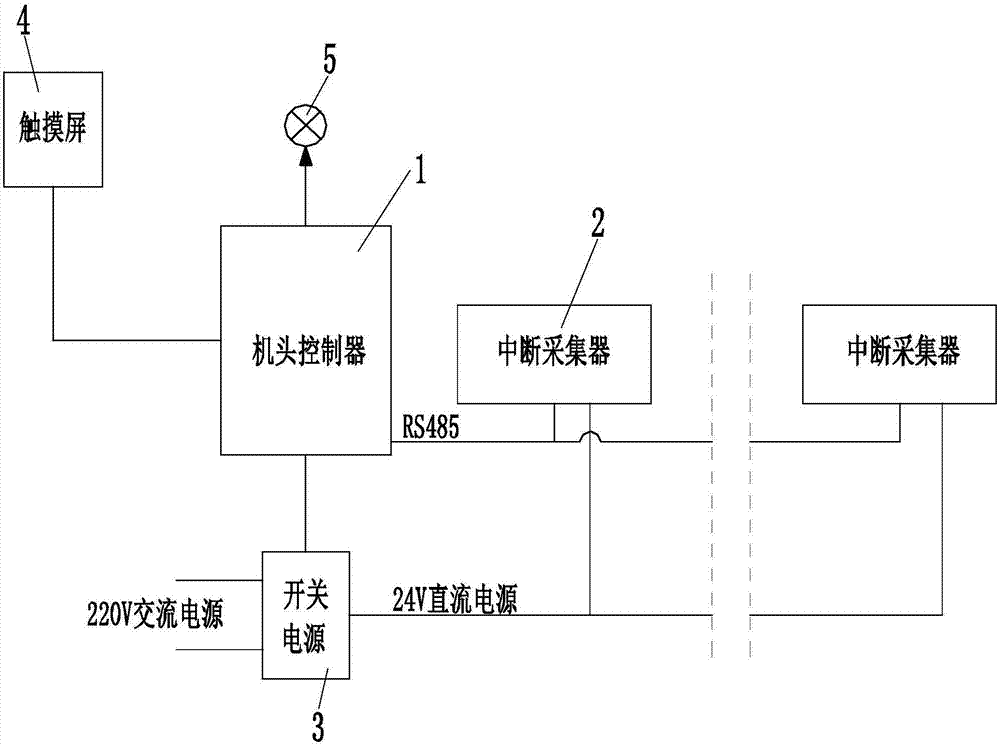

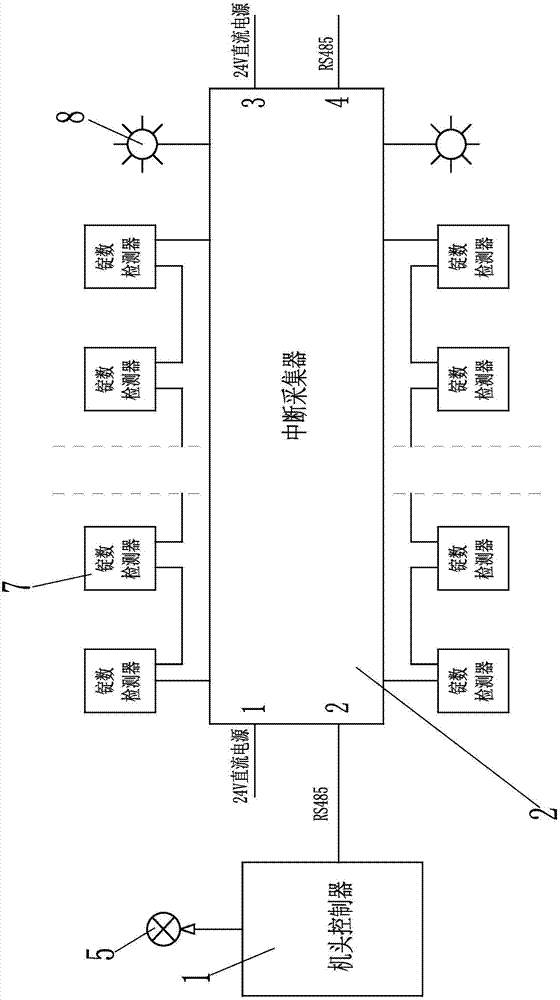

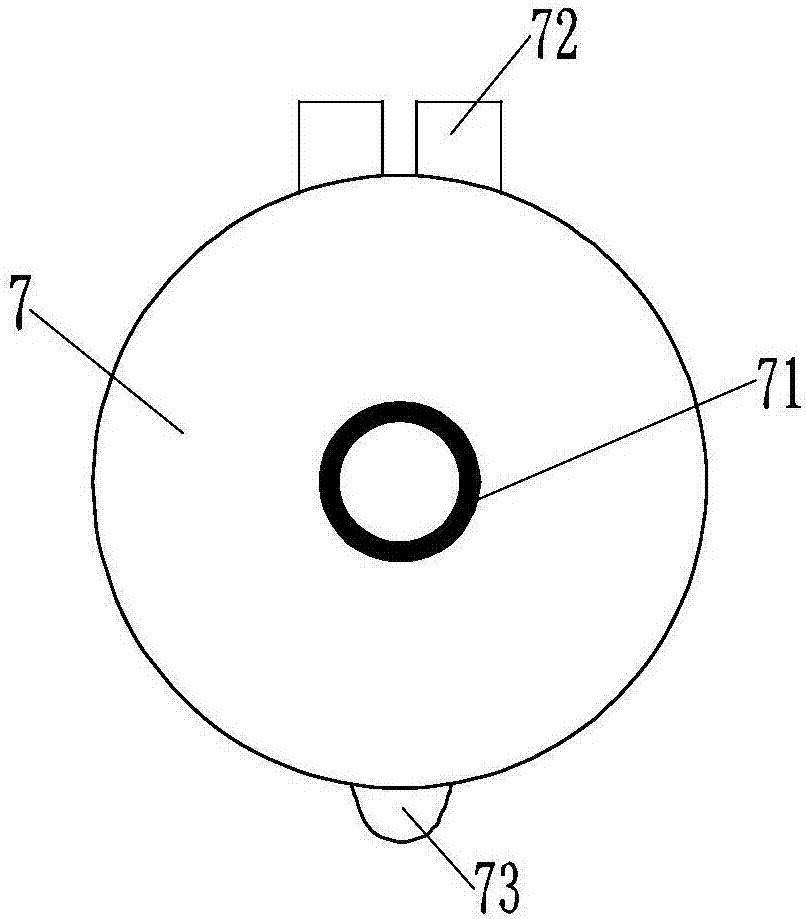

[0021] Such as Figure 1 to Figure 5 As shown, a two-for-one twister capable of detecting the spindle speed and judging the state of the yarn includes a machine head controller 1, which is respectively connected to a switching power supply 3, a touch screen 4, and an alarm light 5, and the machine head The controller 1 is connected to a row of mid-section collectors 2 through the differential transmission mode of the RS485 communication interface, and each mid-section collector 2 is connected to the switching power supply 3 through a 24V DC power supply, and the switching power supply 3 is connected to a 220V AC power supply. The power supply 3 converts the 220V AC power supply into a 24V DC power supply for use in the present invention, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com