Bushing, automobile steering knuckle and automobile

A technology for steering knuckles and bushings of automobiles, which is applied in the direction of steering rods, steering mechanisms, and vehicle components, and can solve problems such as small bushing force, increased failure rate of steering knuckle products, and steering knuckles that do not meet design requirements. The effect of increasing strength and positioning, and improving product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

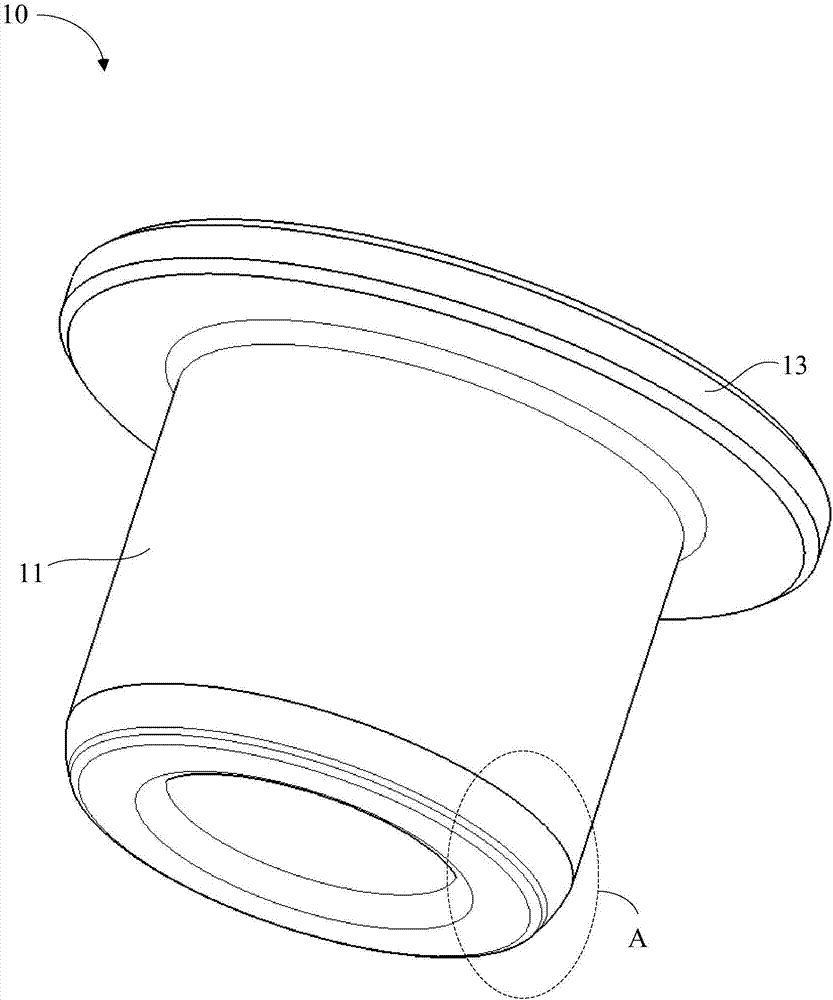

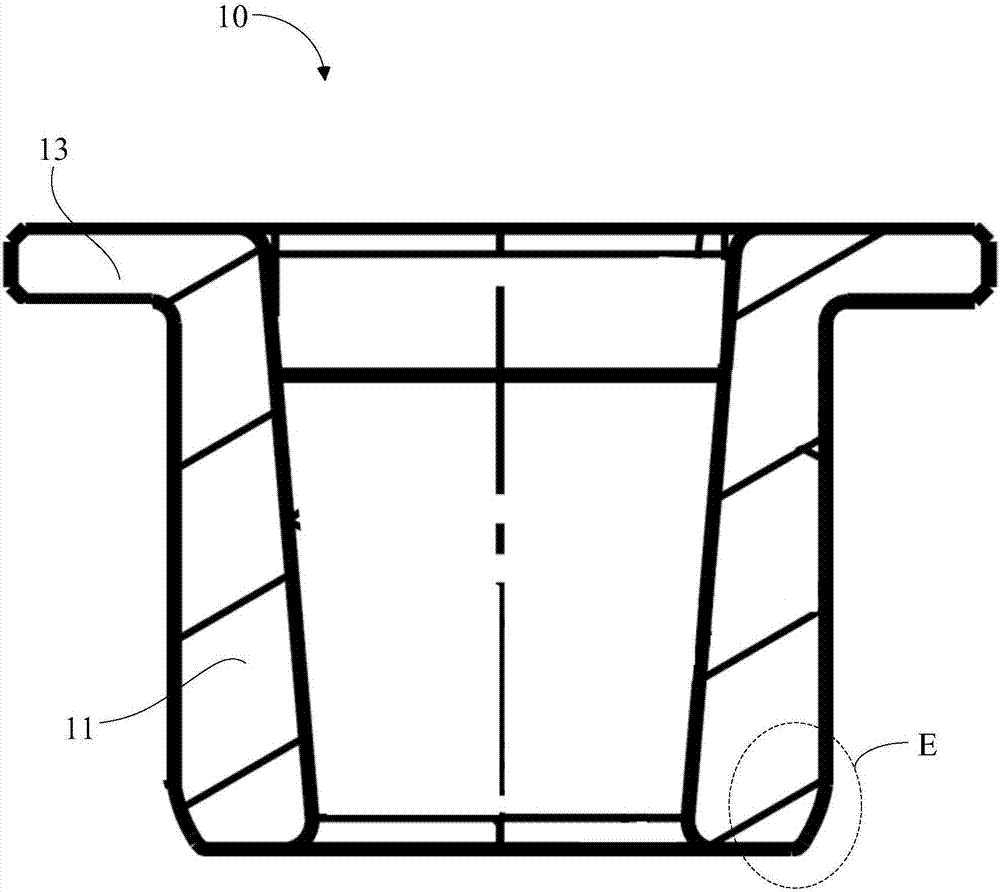

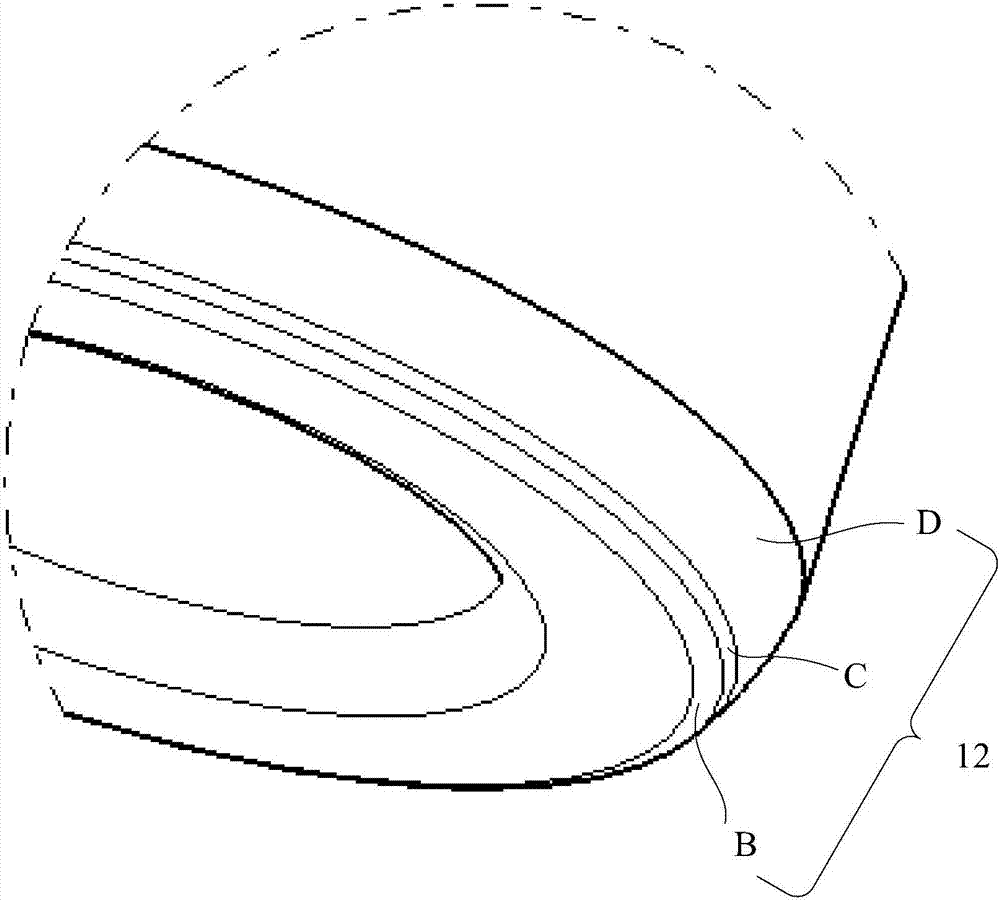

[0023] In the prior art, the end structure of the bushing used to insert into the bushing hole is relatively sharp. During the process of pressing the bushing into the bushing hole of the steering knuckle, a large amount of aluminum chips are easily scraped off the steering knuckle body, causing the bushing to The extrusion force is small, and the steering knuckle does not meet the design requirements. The inserting end of the bushing of the present invention faces the end of the bushing hole with a rounded corner structure, so that the inserting end is smoother and no longer sharp, and the steering knuckle body is not easy to be scraped out of aluminum chips, and the bushing is pressed into the bushing of the steering knuckle After entering the hole, the extrusion force of the bushing increases, and the steering knuckle meets the design requirements.

[0024] In order to make the above objects, features and advantages of the present invention more comprehensible, specific emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com