Invisible high beam

A high beam and invisible technology, applied in the field of invisible high beam, can solve the problems of high beam strong glare stimulation, poor safety, low energy utilization rate, etc., and achieve narrow irradiation range, strong invisible effect, and long irradiation distance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further elaborated below in conjunction with the examples, and the following examples are only for illustration and do not limit the protection scope of the present invention in any way.

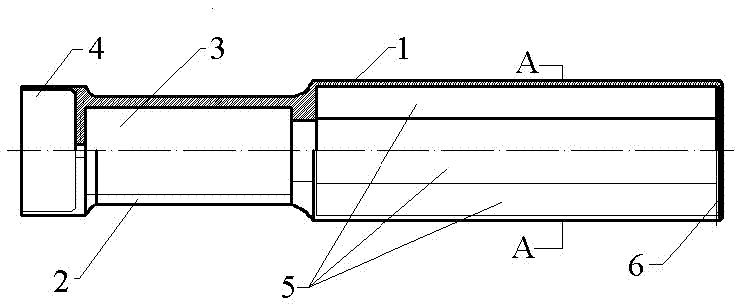

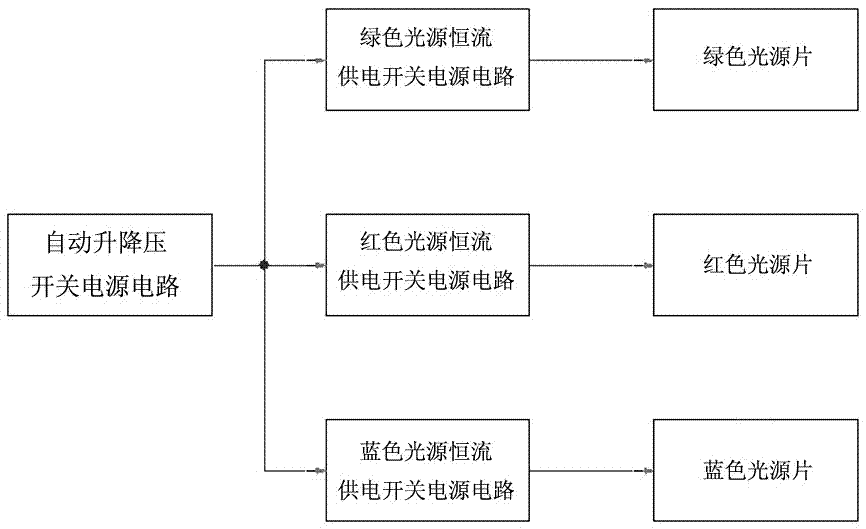

[0030] Such as figure 1 As shown, the flashlight manufactured according to the principle of the invisible high beam of the present invention includes a housing 1 , three single-color light source systems installed in the housing 1 and a three-primary light source driving circuit in the housing 1 .

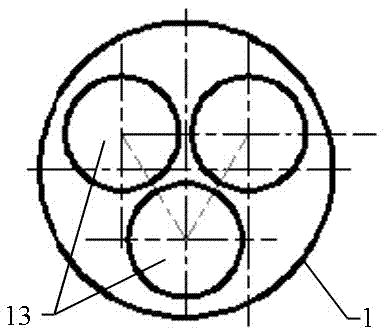

[0031] Wherein, the housing 1 is a cylindrical long tube structure, which is made of aluminum alloy material, and three cylindrical storage bins 13 are arranged in the axial direction on the front half of the housing 1, and the three storage bins 13 are arranged in a triangular shape ( figure 2 ), and a monochromatic light source system 5 is fixed in each storage bin 13 . The rear half of the housing 1 has a thin handle section, which constitutes a handle th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com