Mop drying sink with drying function

A mop and functional technology, applied in the field of mop drying pool, can solve the problems of mop soaking water, easy to breed bacteria, bad smell, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

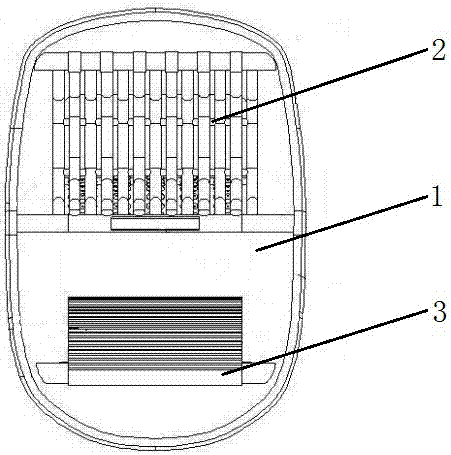

[0014] Such as figure 1 As shown, a mop drying pool with a drying function is composed of a mop pool 1 , a dehydration rack 2 , and a drying heating pipe 3 .

[0015] The mop pool 1 is made of engineering plastics, which not only ensures a longer service life, but also effectively reduces costs.

[0016] The dehydration net frame 2 is installed inside the mop pool, keeping a certain gap with the bottom of the mop pool 1, and the drying heating pipe 3 is installed inside the mop pool 1, opposite to the dehydration net rack 2, so as to ensure that the heat emitted by the drying heating tube can be kept in use. Effectively dries damp mop hair. With the above-mentioned structure, when the mop needs to be dried, the power is turned on to heat the drying heating tube 3 to quickly dry the mop, which solves the problem that the mop is damp and breeds bacteria and produces peculiar smell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com