Conical rubber soft mold removing device and mold removing method

A rubber and soft mold technology, applied in metal processing and other directions, can solve the problems of irregular shape and structure of conical rubber soft mold, unfavorable industrial production and application, etc., to protect surface quality, improve mold ejection efficiency and safety, and ensure no contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

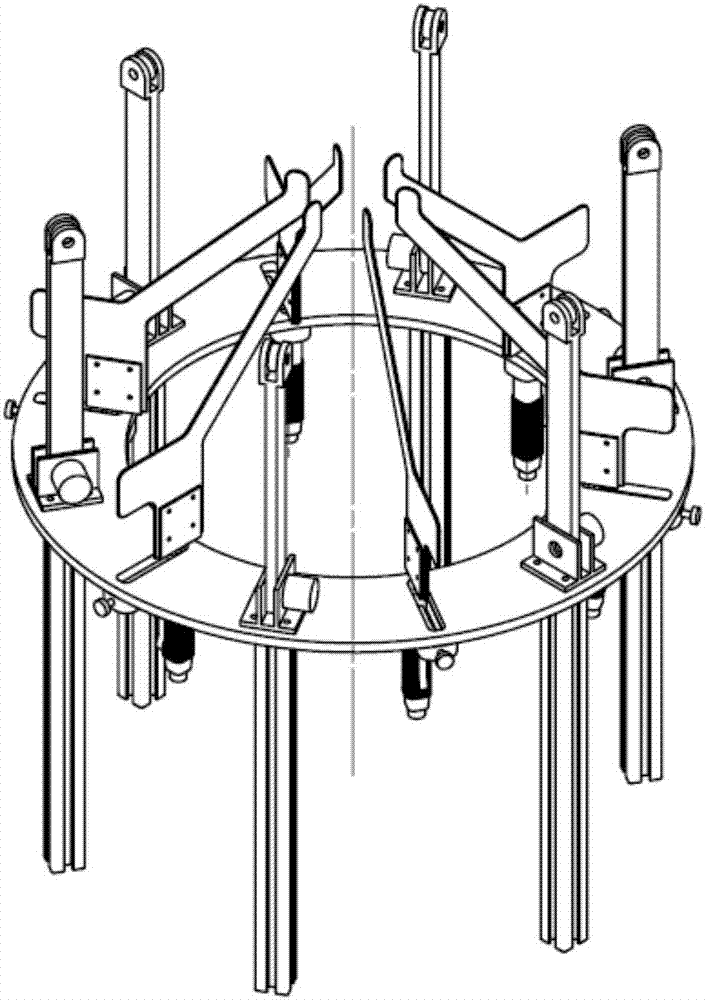

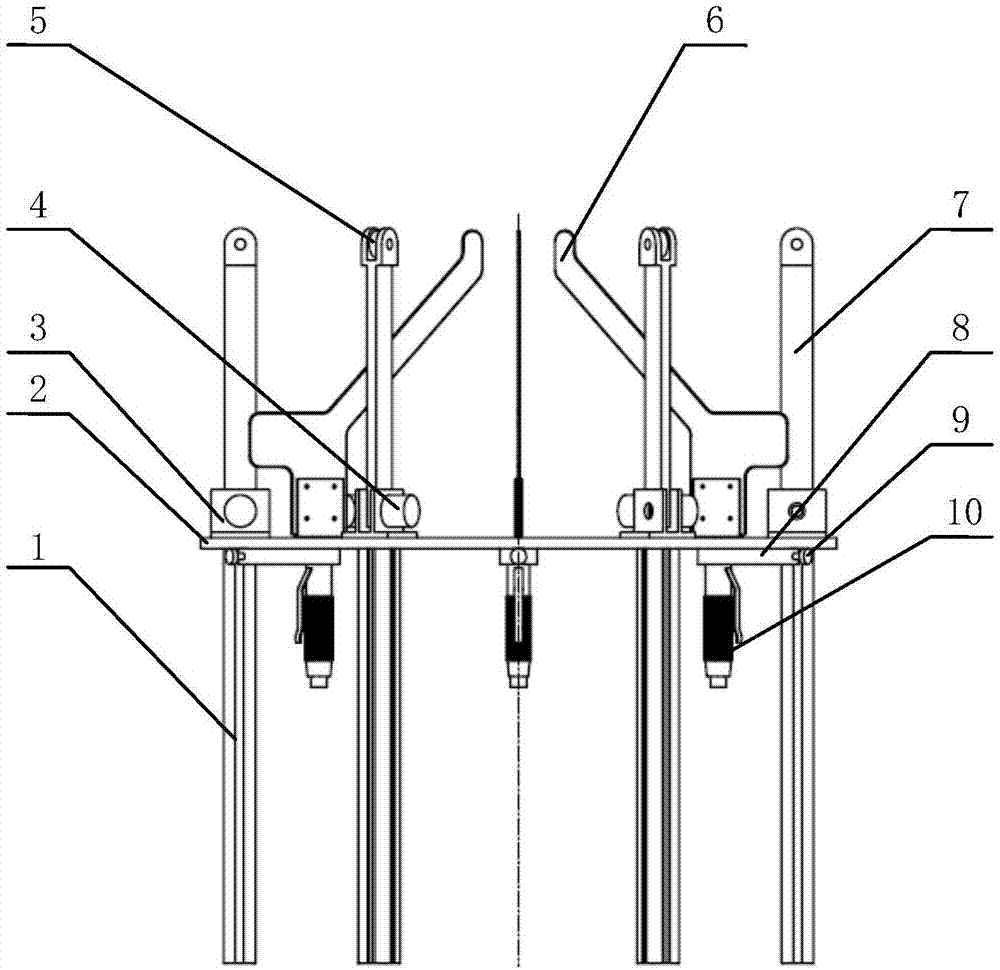

[0031] as attached figure 1 , 2 As shown, a tapered rubber soft mold ejection device is disclosed, including a circular working plane 2, the working plane 2 is arranged on the profile support 1, and on the working plane 2, special-shaped blades 6 and dragging blades are arranged at intervals. Rod 7, all special-shaped blades 6 form a circle on the working plane, all drag rods 7 form a circle on the working plane, the bottom of the special-shaped blade is connected with the pneumatic reciprocator 10, and is integrally installed on the radial adjustment frame 8 , the radial adjustment frame is provided with an adjustment screw 9, and the adjustment screw can move radially by adjusting the radial adjustment frame, thereby adjusting the distance between the special-shaped blades in the center of the working plane;

[0032] At the top of the drag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com