Motor output capability calculating method

A calculation method and technology of output capability, applied in power management, electric vehicles, transportation and packaging, etc., can solve problems affecting the applicability and practicability of electric vehicles, difficult motor output capability, etc., to improve the stability and reliability of use , Good practicability and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

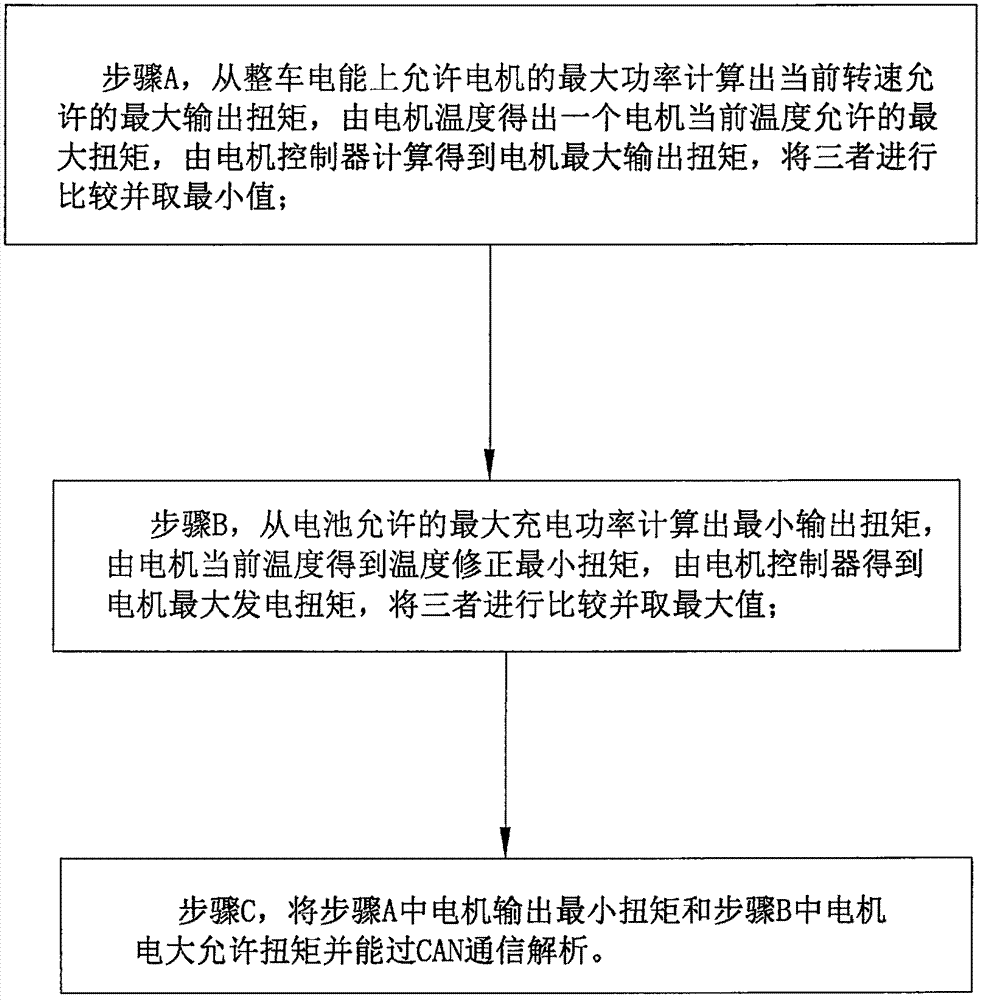

[0032] figure 1 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention.

[0033] See figure 1 , a method for calculating the output capacity of a motor, comprising a motor speed sensor, a stator temperature sensor, a rotor temperature sensor and a motor controller, characterized in that: comprising the following steps:

[0034] Step A, calculate the maximum output torque allowed by the current speed from the maximum power allowed by the motor on the electric energy of the whole vehicle, obtain a maximum torque allowed by the current temperature of the motor from the motor temperature, and calculate the maximum output torque of the motor by the motor controller, and combine the three compare and take the minimum value;

[0035] Step B, calculate the minimum output torque from the maximum charging power allowed by the battery, obtain the temperature-corrected minimum torque from the current temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com