Wheel-leg switching mechanism

A technology of wheel legs and shanks, which is applied in the field of mechanism design, can solve the problems of poor road adaptability, slow moving speed, and poor terrain adaptability of walking wheels, and achieve strong road adaptability, reduced driving torque, and strong bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

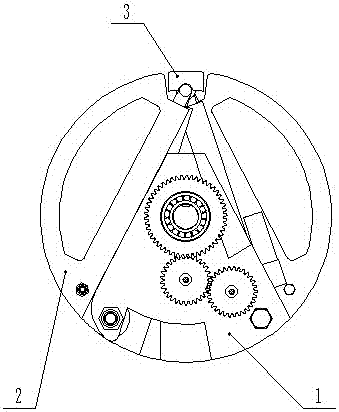

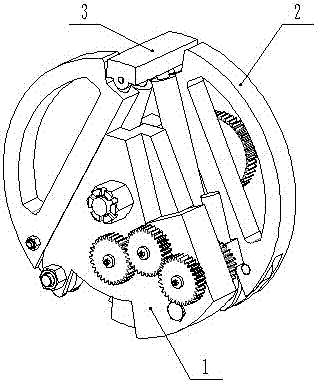

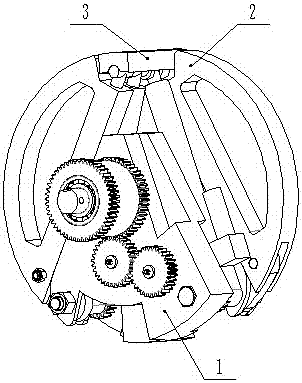

[0016] Examples, see attached Figure 1-9 , a wheel-leg transformation mechanism, comprising a wheel thigh 1, a wheel shank 2 and a wheel foot 3, characterized in that the two wheel shanks 2 are mounted on the wheel thigh 1 through the shank mounting shaft 20, and the wheel foot 3 is passed through the wheel foot pin 23 is installed on a wheel calf 2; the thigh bracket 4 of the wheel thigh 1 is fixedly connected with the wheel leg drive shaft 7 with a key, and is fastened by a nut 13, and the calf expansion drive gear 5 is supported on the wheel leg drive shaft 7 through the bearing 6 On the top, the transmission gear Ⅰ8 and the transmission gear Ⅳ14 are fixedly installed on both ends of the transmission shaft Ⅰ9 through key connection, the transmission shaft Ⅰ9 is installed in the round hole of the thigh support 4, the transmission gear Ⅰ8 meshes with the calf stretching drive gear 5, and the transmission gear Ⅱ11 It is fixedly installed on both ends of the transmission shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com