Novel spinning cradle

A cradle, a new type of technology, applied in the direction of spinning machines, textiles, papermaking, drafting equipment, etc., can solve the problems of high energy consumption of pneumatic cradles, easy yarn breakage, etc., to achieve simple structure, reduce breakage rate, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

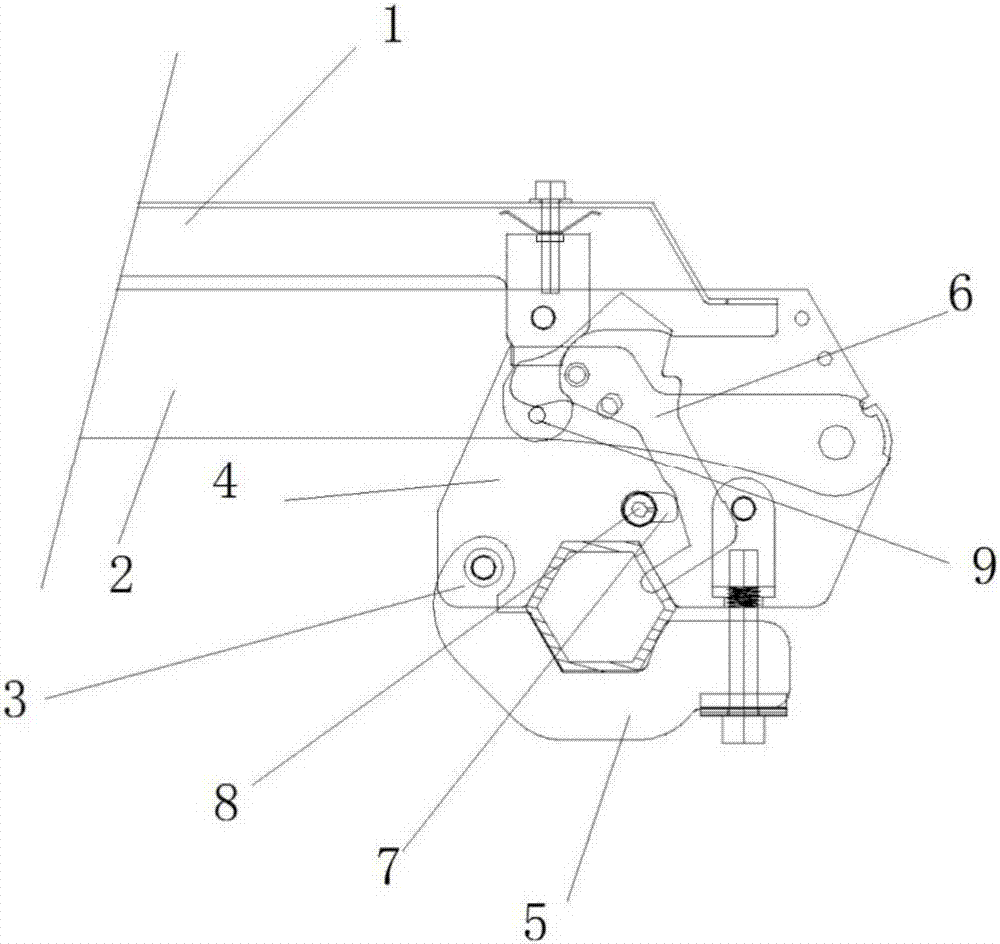

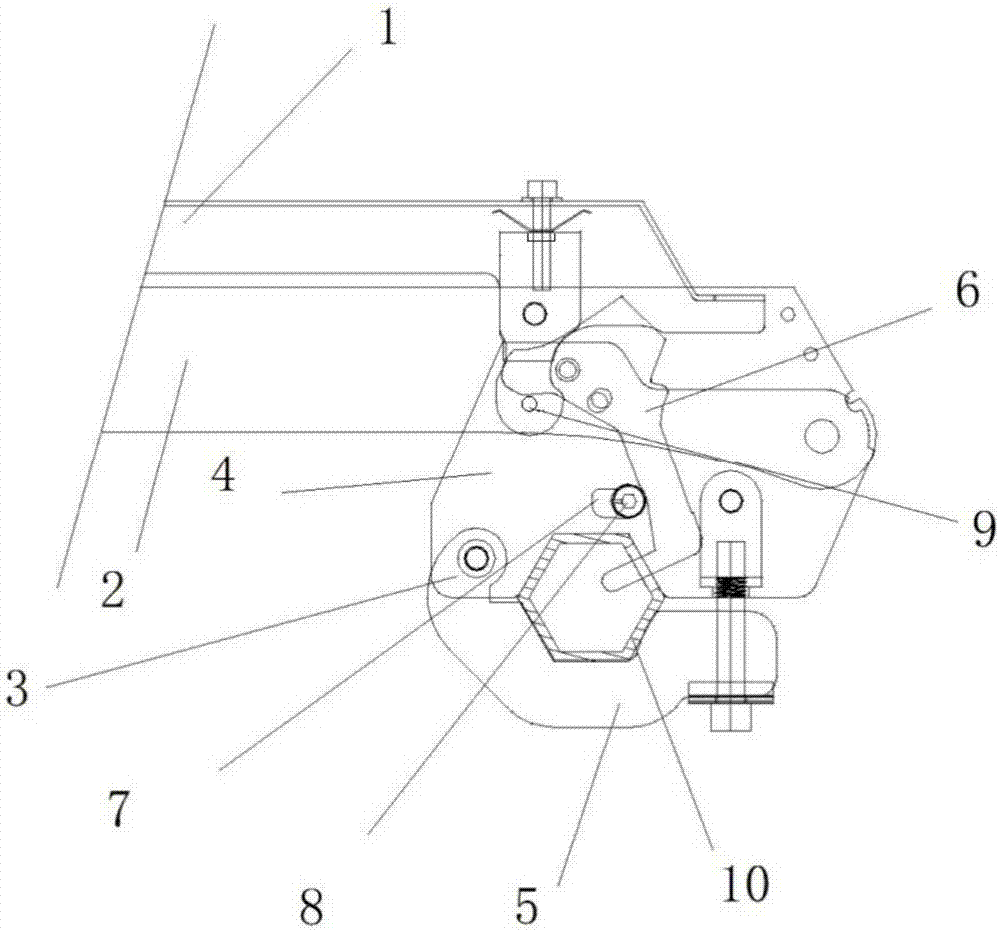

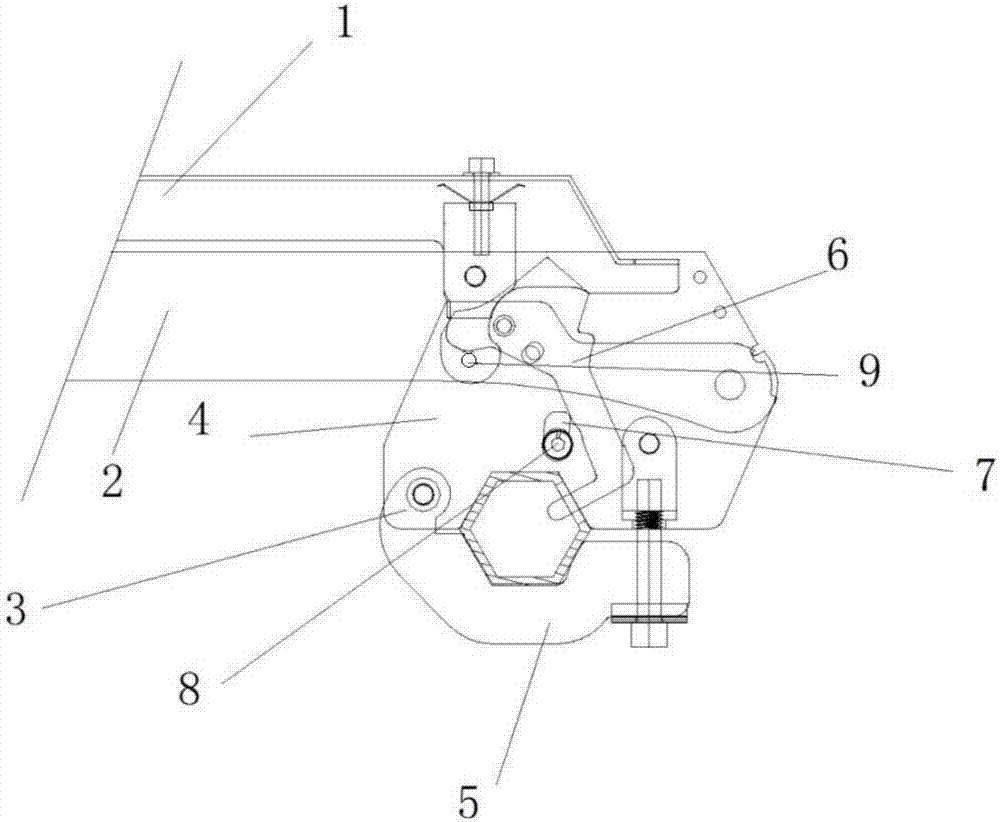

[0022] The invention discloses a novel spinning cradle, the handle 1 and the cradle seat 3 are movably connected with the rocker arm 2, the cradle seat 3 is composed of an upper fixing card 4 and a lower fixing card 5, a pressure transmission crank 6, an eccentric The part 7 is set in the upper fixed card 4, and the pin shaft 9 is set at the lower end of the movable connection point between the handle 1 and the rocker arm 2. The end of the eccentric part 7 away from the rotating shaft 8 is the front end, and the end close to the rotating shaft 8 is the rear end. By rotating the eccentric part 7 Finely adjust the position of the pressure transmission crank 6 around its fulcrum, change the pressure of the pressure transmission crank 6 on the pin shaft 9, and then change the force of the pressure transmission crank 6 on the cradle.

[0023] Such as Figure 1 ~ Figure 3 As shown, it is an embodiment in which the eccentric component 7 is arranged on the lower side of the pressure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com