Small-size self-locking explosion-proof connector used for power cable wiring and installation method thereof

A technology for power cables and connectors, applied in the field of small explosion-proof connectors, can solve problems such as difficulty in ensuring construction quality, incomplete filling, and long curing time for silicone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

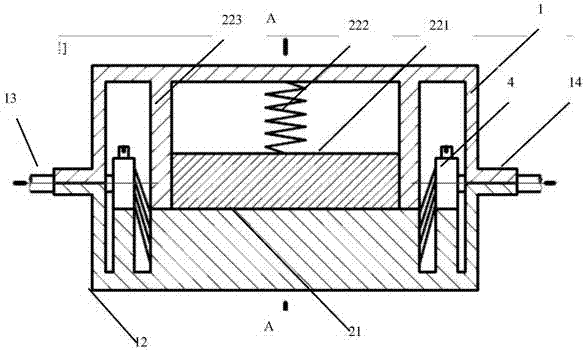

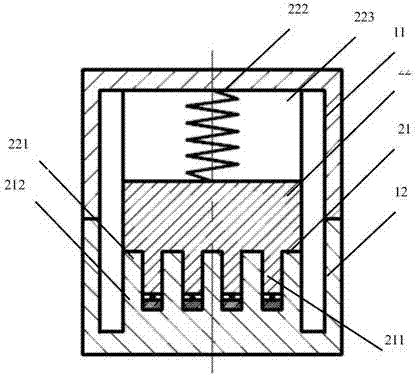

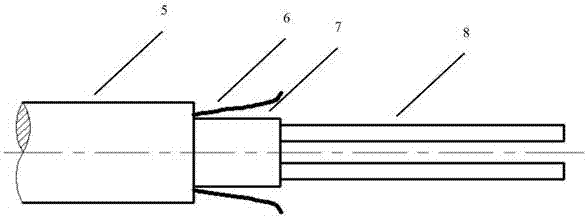

[0036] Figure 1-3 The structure of the self-locking explosion-proof connector of the present invention is schematically shown, and the explosion-proof connector includes a connector housing 1 , a connecting device 2 , a sealing device 3 , and a wire pressing device 4 .

[0037] The connector housing 1 is a square tubular body with a stepped inner hole, and is composed of two parts, an upper shell 11 and a lower shell 12 . The upper casing 11 and the lower casing 12 are provided with self-locking bayonet openings, and the self-locking bayonet openings may be of a known structure (not shown in the figure). A gasket (not shown in the figure) is arranged between the upper casing 11 and the lower casing 12 to ensure the sealing between the upper and lower casings. Both ends of the housing 1 have an inlet end 13 and an outlet end 14 of the cable.

[0038] The connecting device 2 is arranged inside the housing 1 and includes a cable penetrating device 21 and a cable pressing devic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com