Lifting mechanism on deslagging machine

A slag removal machine and hoisting technology, applied in the directions of transportation and packaging, load hoisting components, etc., can solve the problems of frequent use, falling off pins, complicated workmanship of hoisting chains, etc., and achieve the effect of reducing production cost and use cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

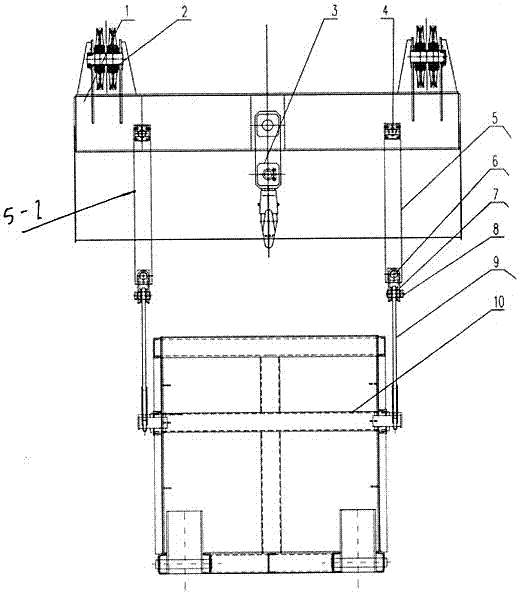

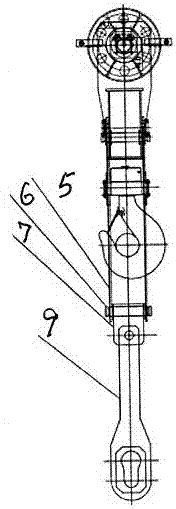

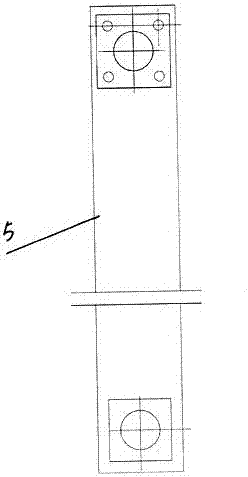

[0008] Embodiments are described in detail in conjunction with the above accompanying drawings, as figure 1 and figure 2 As shown, the moving pulley block 2 is respectively fixed left and right by the axle frame and the suspension beam skeleton 1, and the moving pulley block is connected with the hoisting mechanism of the trolley with a steel wire rope. The lifting hoisting mechanism of the trolley is a prior art, and will not be repeated here In detail, a hook device 3 is installed in the middle of the lower side of the hoisting frame. When the crane does not use a hopper, it can be used as a general-purpose crane. The two ends of the lower side of the hoisting beam frame each have a bore hole, and the double hanging plates pass through. The plate shaft 4 is assembled in the boring hole and fixed by the clamping plate. The double hanging plate is composed of the hanging plate 5 and another hanging plate 5-1. The lower end of the double hanging plate is passed through the U-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com