Valve core of three-position three-way valve

A three-position three-way valve and spool technology, applied in the field of valve spools, can solve the problems of high cost, easy corrosion of copper, and generation of copper ions, etc., and achieve the effect of reducing production cost and use cost, and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

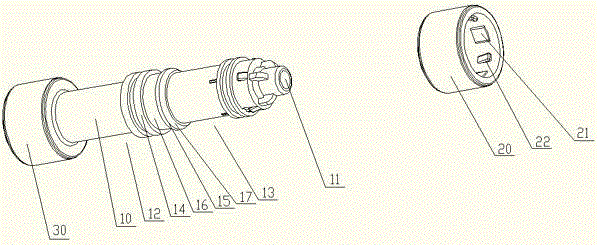

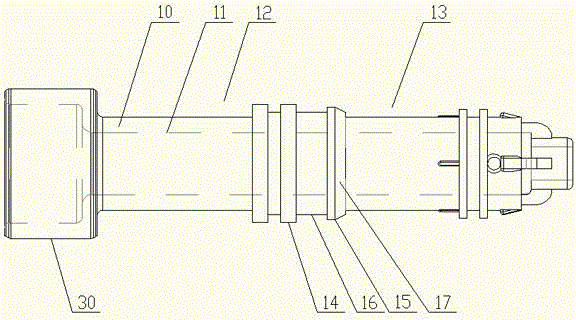

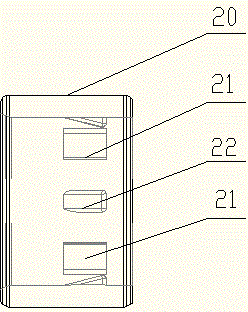

[0020] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0021] Such as Figure 1 to Figure 3 As shown, a valve core of a three-position three-way valve includes a cylindrical body 10 made of plastic with a first axial water flow channel 11 inside, and a plastic annular bushing is detachably provided on the body 10 20. The bush 20 is sleeved on the body 10, and can rotate relative to the body 10 in the circumferential direction, and does not slide relative to the body 10 in the axial direction. Under the wrapping of the valve, a second valve is formed between the bush 20 and one end of the body 10 A third water flow channel 13 is formed between the water flow channel 12 and the other end of the bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com