Method for improving local flexural capacity of staggered-truss chord members

A truss chord and bearing capacity technology, applied in the direction of building, building structure, etc., can solve the problems affecting the use of buildings, and achieve the effect of saving steel consumption and facilitating welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

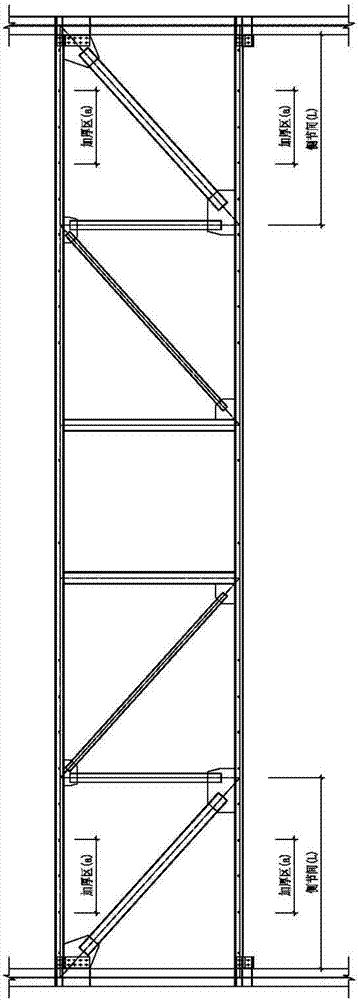

[0024] Please refer to the attached figure 1 To attach Figure 4 As shown, the present invention is a method for improving the local bending capacity of the chord of a staggered truss, comprising the following steps:

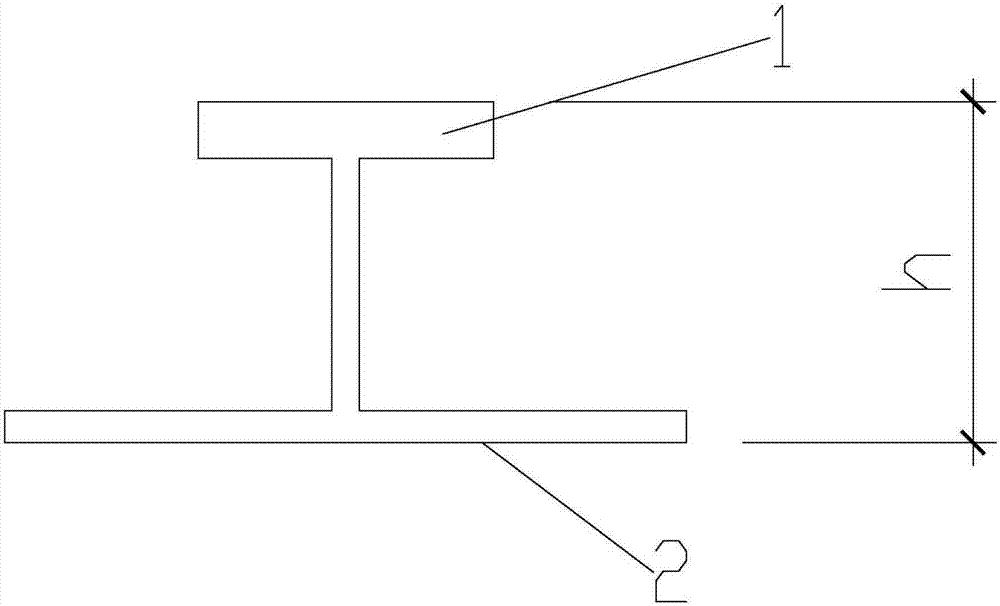

[0025] 1) Determine the section moment of inertia I of the chord according to the section size of the truss chord, and determine the elastic modulus E and strength design value f according to the steel type of the chord d , to obtain the design value M1 of the flexural bearing capacity of the chord, M1=f d *E*I;

[0026] 2), analyze and calculate the structural stress of the truss, and obtain the maximum bending moment M2 of the internode chords on both sides of the truss close to the column. When M2>M1, the flexural bearing capacity of the internodes on both sides is insufficient, and steel plates need to be welded;

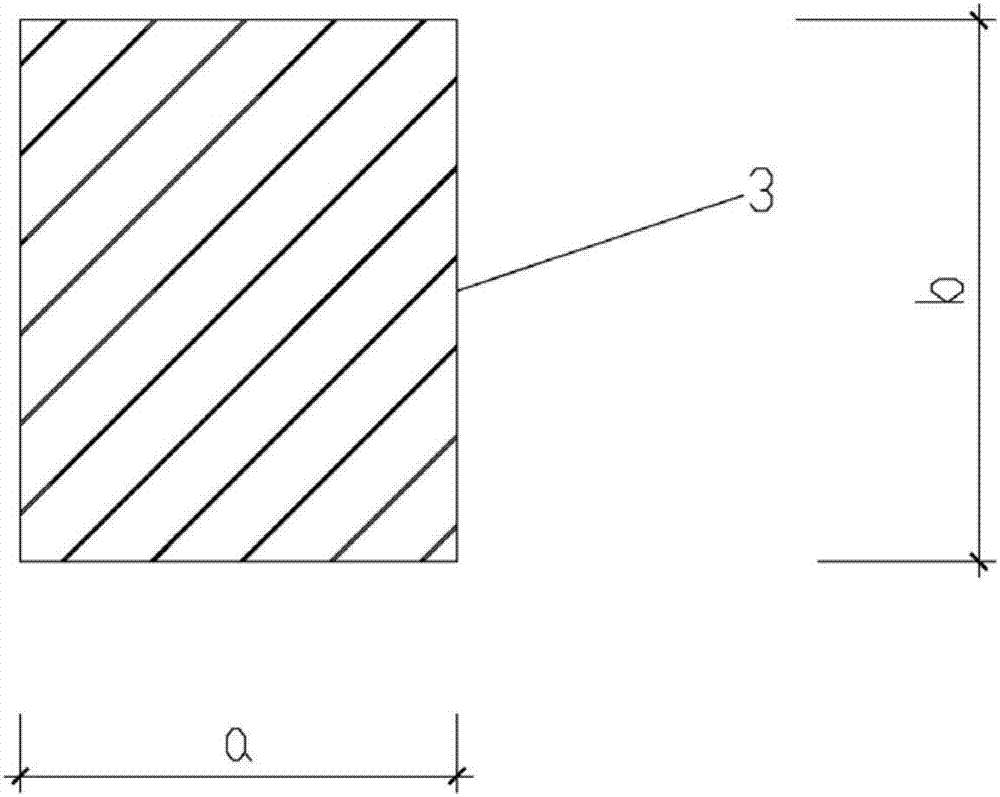

[0027] 3), the length a of the steel plate is determined according to the range of the internode bending moment on both sides exceeding M1, ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com