Material level detection device and container of high-temperature solid material

A material level detection, high temperature solid technology, applied in the direction of displaying liquid level indicator through pressure measurement, can solve the problems of material level measurement without high temperature material, inaccurate measurement results, inability to withstand high temperature, etc. The effect of high measurement accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

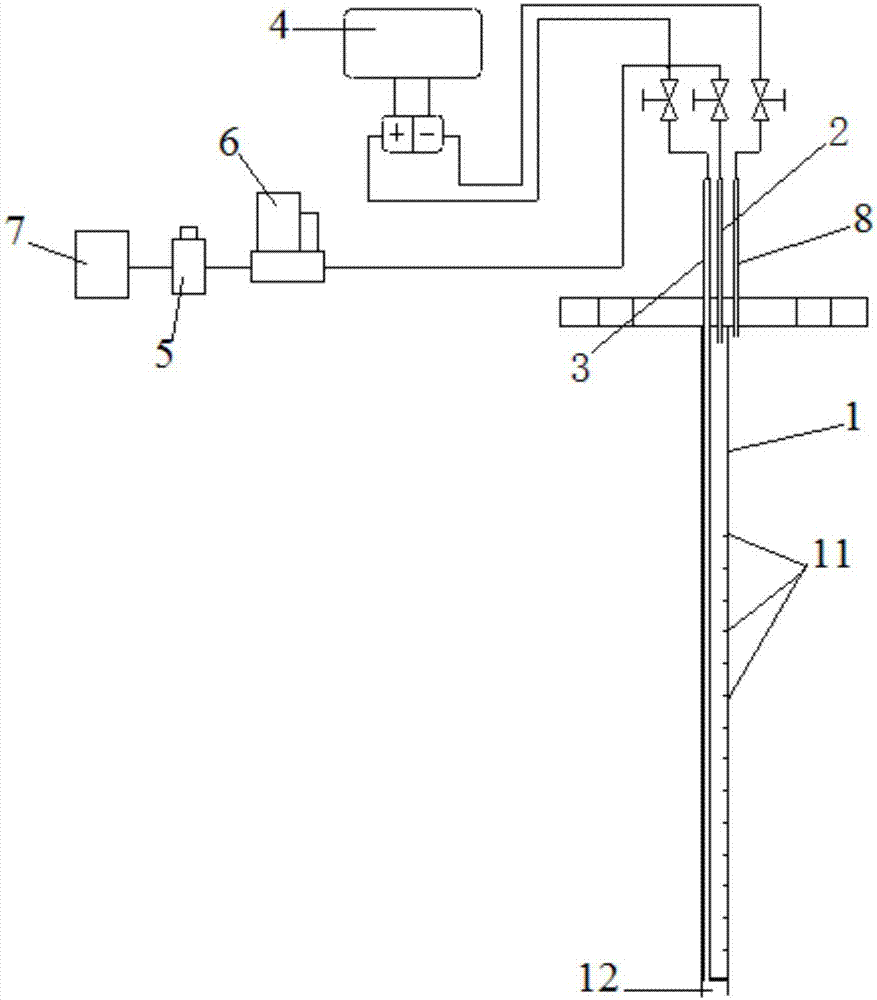

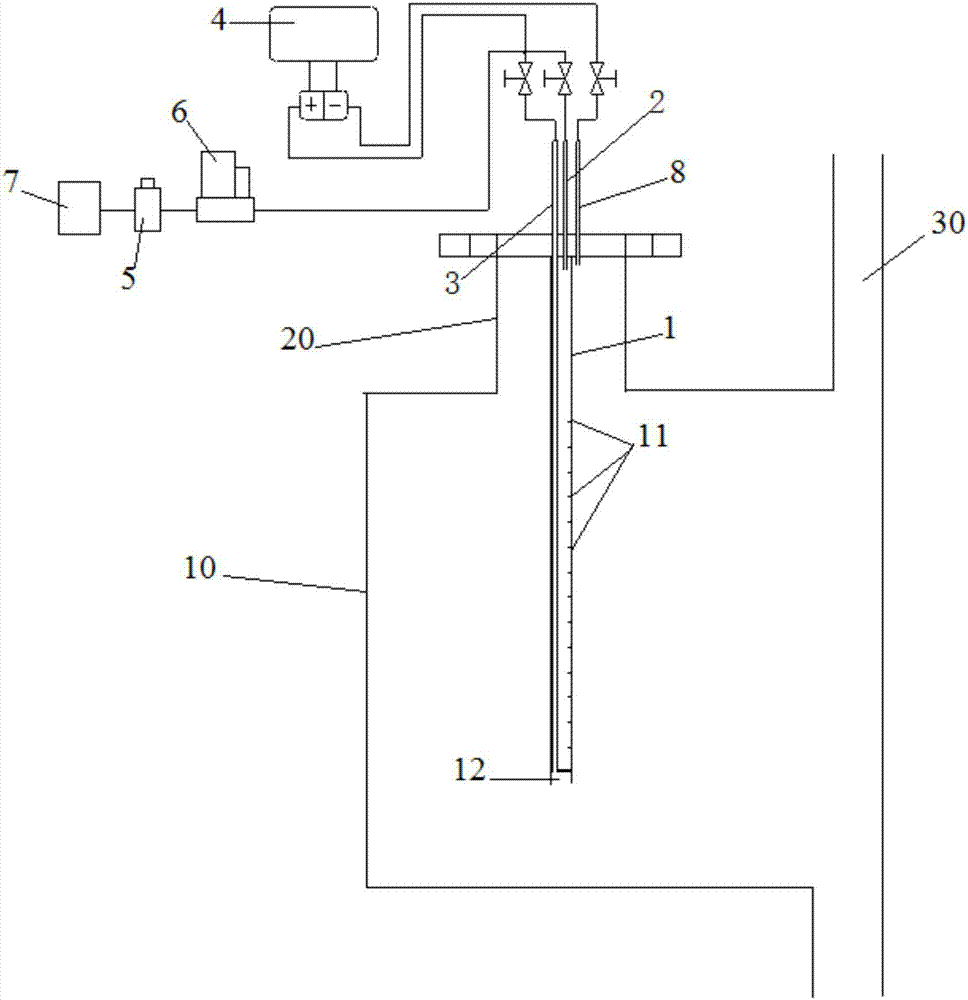

[0032] In this embodiment, when detecting the material level, the use method may be to insert the end of the high temperature resistant detection tube 1 close to or contact the bottom of the housing 10 .

[0033] At this time, the plurality of first material level detection ports 11 can function as depth scales. The solid material accumulated in the container can block the first material level detection port 11 below the height of the material level. When all the first material level detection ports 11 can be ventilated, the pressure value detected by the pressure sensor on the first air pipe 2 is a small reference value. As the material gradually accumulates in the container, the material level rises and gradually blocks the first material level detection port 11 from bottom to top. Since the unblocked first material level detection port 11 gradually decreases, the first material level detection port 11 is gradually reduced. The air pressure in the gas pipe 2 increases gradu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com