Automatic pocket ironing machine

A pocket machine and pocket technology, which is applied in the field of garment production, can solve the problems of cumbersome ironing process and multiple processes, and achieve the effects of improving efficiency, reducing workload and improving ironing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

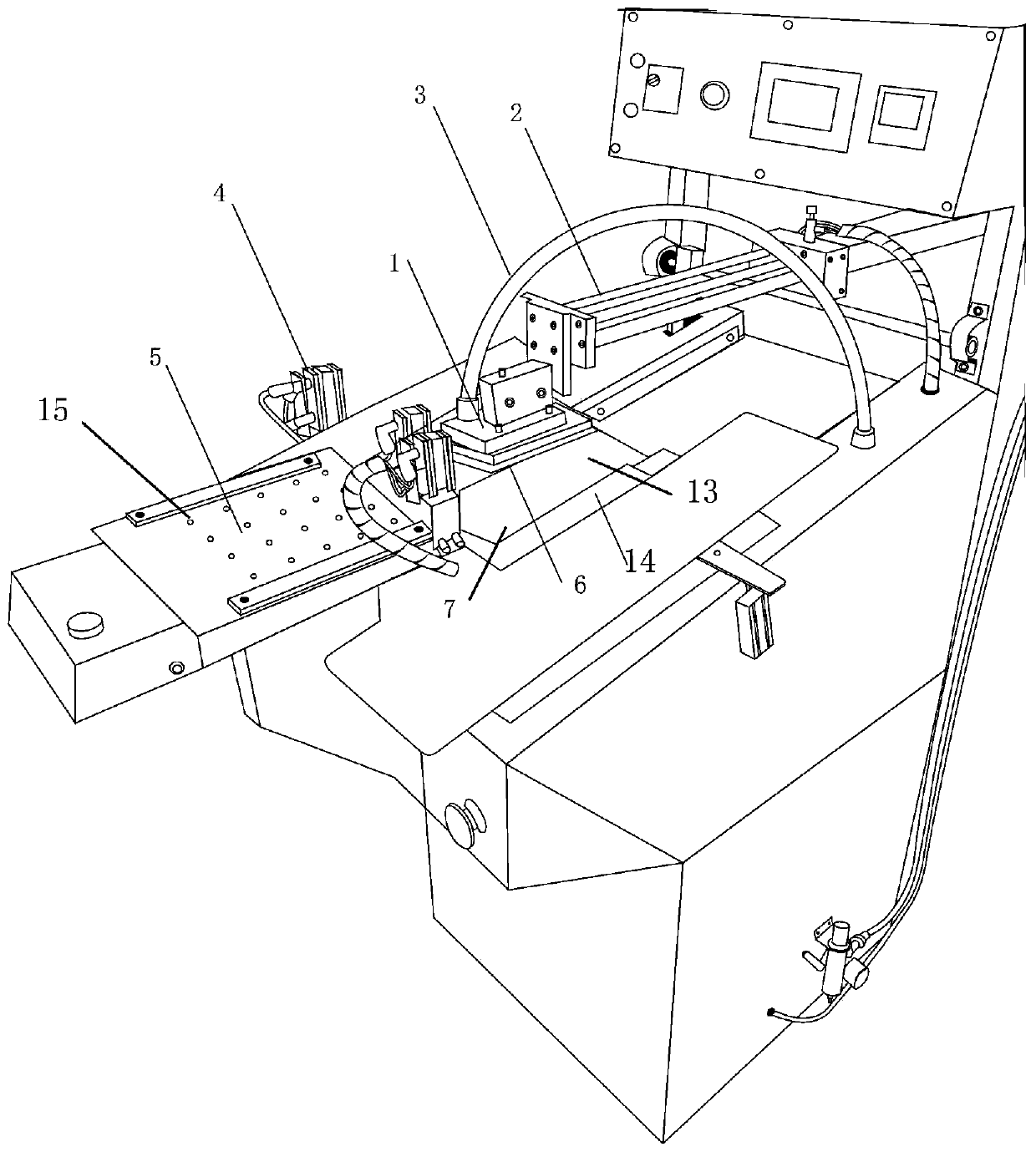

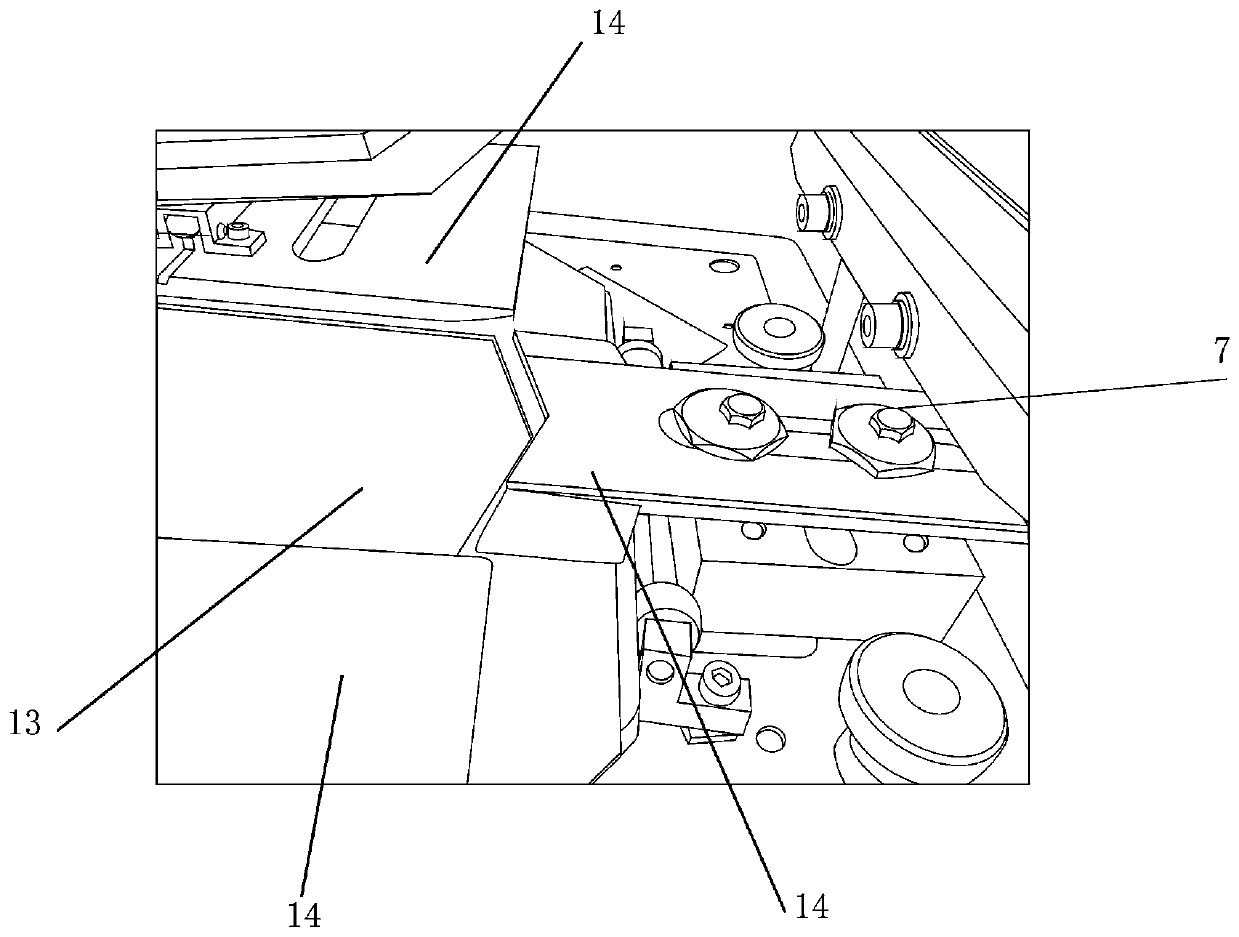

[0032] Such as Figure 1-4 Shown, a kind of automatic bag ironing machine is characterized in that, comprises

[0033] Pocket mould, said pocket mold comprises pocket lower mold pre-ironing device 7 and pocket upper mold 6, said pocket lower mold pre-ironing device 7 matches with pocket upper mold 6, and is used for folding and ironing the carrier sheet;

[0034] Telescopic mechanical arm 2, the telescopic mechanical arm 2 is connected with the mold 6 on the pocket, and drives the mold 6 on the pocket to move horizontally and vertically;

[0035] Pre-feeding device 1, the pre-feeding device 1 is arranged between the mold 6 on the pocket and the telescopic mechanical arm 2, and is used to drive the mold 6 on the pocket to move;

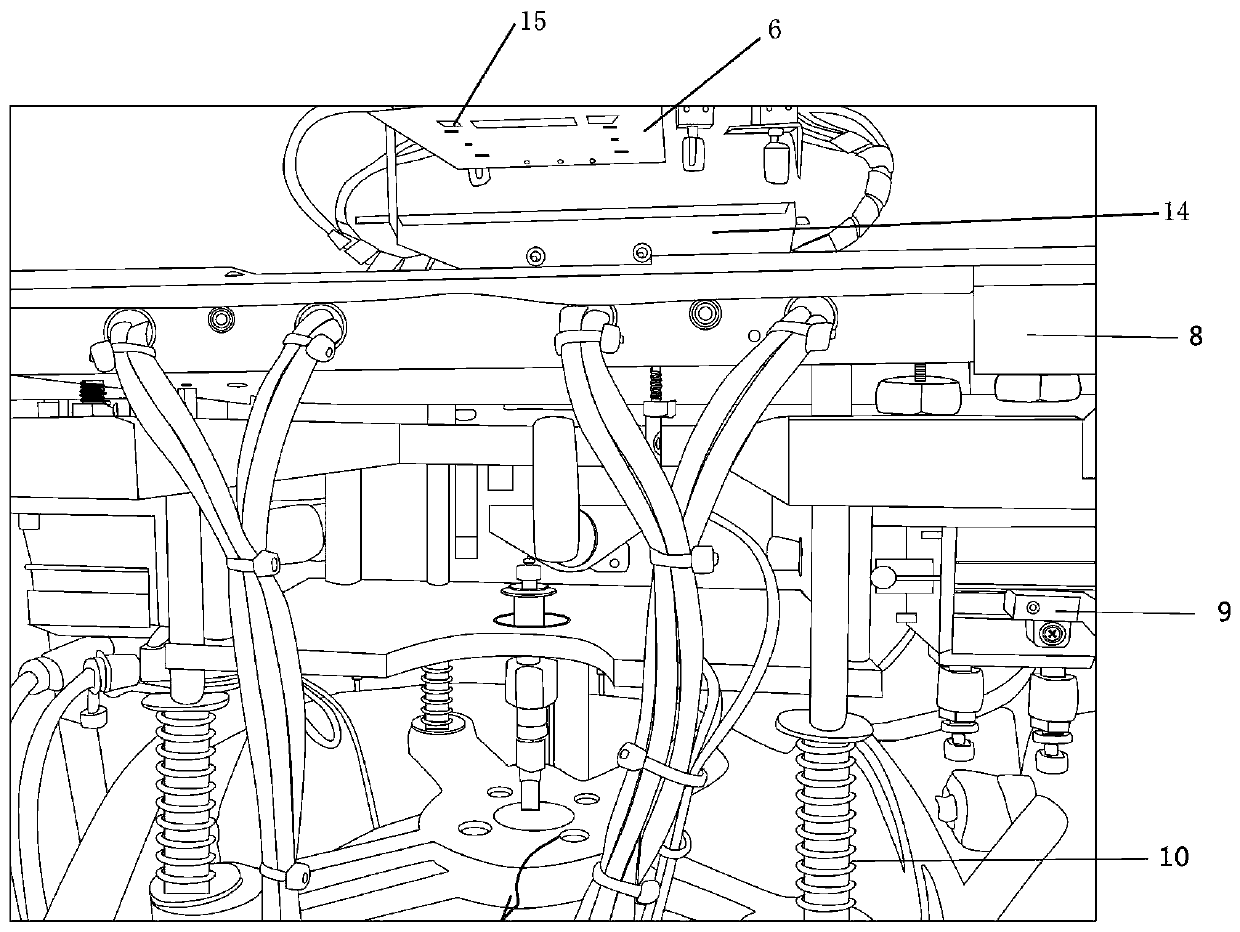

[0036] An aspirating device, the aspirating device includes a cylinder and an aspirating pipeline 3 communicating with the cylinder, and the aspirating pipeline 3 communicates with the air hole 15 for absorbing and fixing the slide.

[0037] The abov...

Embodiment 2

[0049] Such as Figure 1-4 Shown, a kind of automatic bag ironing machine is characterized in that, comprises

[0050] Pocket mould, said pocket mold comprises pocket lower mold pre-ironing device 7 and pocket upper mold 6, said pocket lower mold pre-ironing device 7 matches with pocket upper mold 6, and is used for folding and ironing the carrier sheet;

[0051] Telescopic mechanical arm 2, the telescopic mechanical arm 2 is connected with the mold 6 on the pocket, and drives the mold 6 on the pocket to move horizontally and vertically;

[0052] Pre-feeding device 1, the pre-feeding device 1 is arranged between the mold 6 on the pocket and the telescopic mechanical arm 2, and is used to drive the mold 6 on the pocket to move;

[0053] An aspirating device, the aspirating device includes a cylinder and an aspirating pipeline 3 communicating with the cylinder, and the aspirating pipeline 3 communicates with the air hole 15 for absorbing and fixing the slide.

[0054] The abov...

Embodiment 3

[0060] Such as Figure 1-4 Shown, a kind of automatic bag ironing machine is characterized in that, comprises

[0061] Pocket mould, said pocket mold comprises pocket lower mold pre-ironing device 7 and pocket upper mold 6, said pocket lower mold pre-ironing device 7 matches with pocket upper mold 6, and is used for folding and ironing the carrier sheet;

[0062] Telescopic mechanical arm 2, the telescopic mechanical arm 2 is connected with the mold 6 on the pocket, and drives the mold 6 on the pocket to move horizontally and vertically;

[0063] Pre-feeding device 1, the pre-feeding device 1 is arranged between the mold 6 on the pocket and the telescopic mechanical arm 2, and is used to drive the mold 6 on the pocket to move;

[0064] An aspirating device, the aspirating device includes a cylinder and an aspirating pipeline 3 communicating with the cylinder, and the aspirating pipeline 3 communicates with the air hole 15 for absorbing and fixing the slide.

[0065] The abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com