A preparation of porous resin microspheres with controllable surface growth morphology tio 2 Methods

A technology of porous resin and surface growth, applied in chemical instruments and methods, chemical/physical processes, catalysts for physical/chemical processes, etc. Conductive capacity, high adsorption capacity, obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

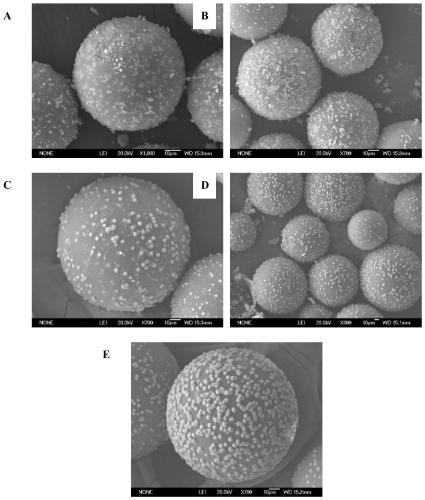

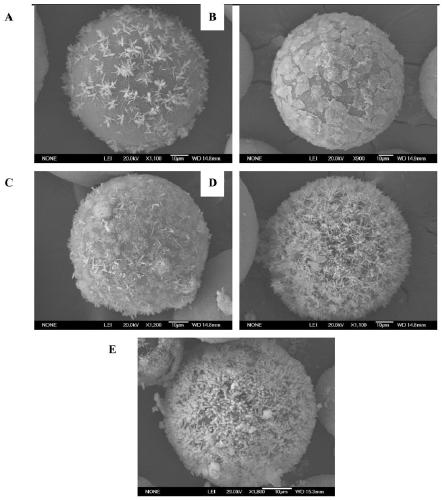

[0020] Embodiment 1: porous resin microsphere / TiO 2 Preparation of composite microspheres

[0021] Preparation mass concentration is the n-butyl titanate solution of 100g / L, and wherein solvent is the hydrochloric acid solution that concentration is 5mol / L; 3.0g porous poly (styrene-divinylbenzene) microspheres are added to 30g above-mentioned n-butyl titanate butyl ester solution, and ultrasonically dispersed. Transfer the dispersed solution to a polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle, then place the hydrothermal reaction kettle in a high-temperature oven, slowly raise the temperature to 180°C, and react for 12 hours, then naturally cool to room temperature, and wash the product with water And after centrifugation, the porous poly(styrene-divinylbenzene) microspheres / TiO 2 Composite microspheres.

Embodiment 2

[0022] Embodiment 2: porous resin microsphere / TiO 2 Preparation of composite microspheres

[0023] Preparation mass concentration is the tetraisopropyl titanate solution of 100g / L, and wherein solvent is that concentration is 5mol / L hydrochloric acid solution; 2.5g porous poly(glycidyl methacrylate-divinylbenzene) microspheres are added to 30g The above tetraisopropyl titanate solution, and ultrasonic dispersion. Transfer the dispersed solution to a polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle, then place the hydrothermal reaction kettle in a high-temperature oven, slowly raise the temperature to 200°C, and react for 6 hours, then naturally cool to room temperature, and wash the product with water And after centrifugation, the porous poly(glycidyl methacrylate-divinylbenzene) microspheres / TiO 2 Composite microspheres.

Embodiment 3

[0024] Embodiment 3: porous resin microsphere / TiO 2 Preparation of composite microspheres

[0025] Preparation mass concentration is the n-butyl titanate solution of 100g / L, and wherein solvent is that concentration is 4mol / L hydrochloric acid solution; 3.0g porous poly(glycidyl methacrylate-divinylbenzene) microspheres are added to 30g above-mentioned In n-butyl titanate solution, and ultrasonically dispersed. Transfer the dispersed solution to a polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle, then place the hydrothermal reaction kettle in a high-temperature oven, slowly raise the temperature to 220°C, react for 9 hours, cool to room temperature naturally, and wash the product with water And after centrifugation, the porous poly(glycidyl methacrylate-divinylbenzene) microspheres / TiO 2 Composite microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com