Passageway gas temperature regulator and hyperbaric oxygen chamber system

A technology of gas temperature and hyperbaric oxygen chamber, which is applied in the directions of transportation and packaging, refrigeration and liquefaction, respiratory protection containers, etc., and can solve the problems that cannot fundamentally solve the temperature of the cabin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to specific embodiments and drawings.

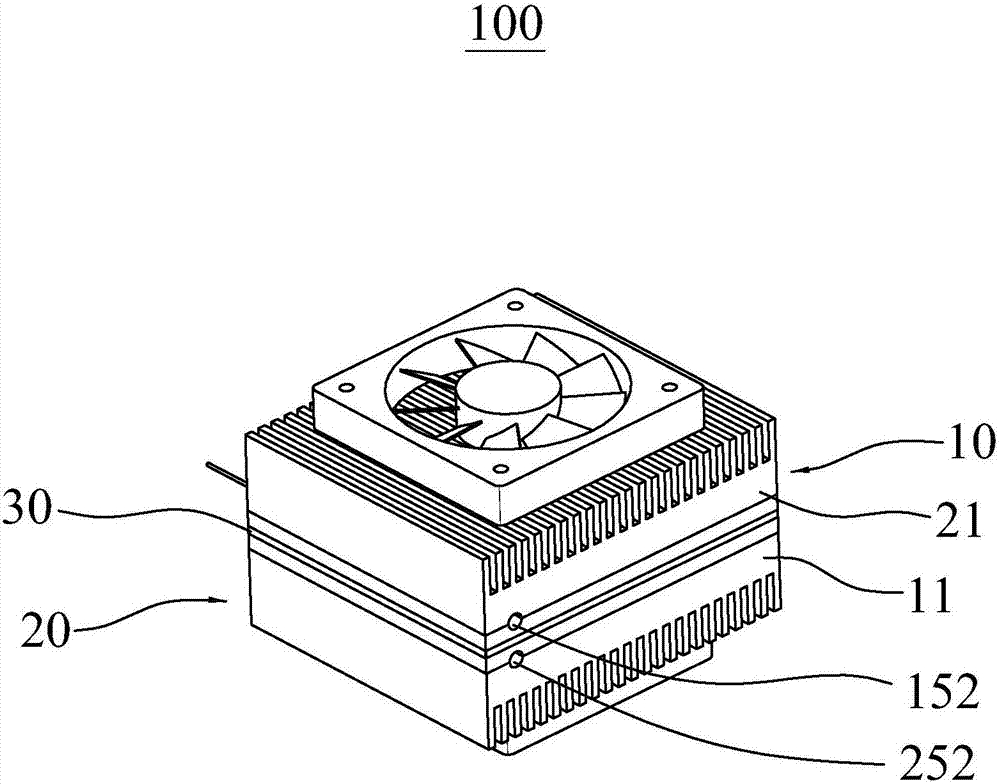

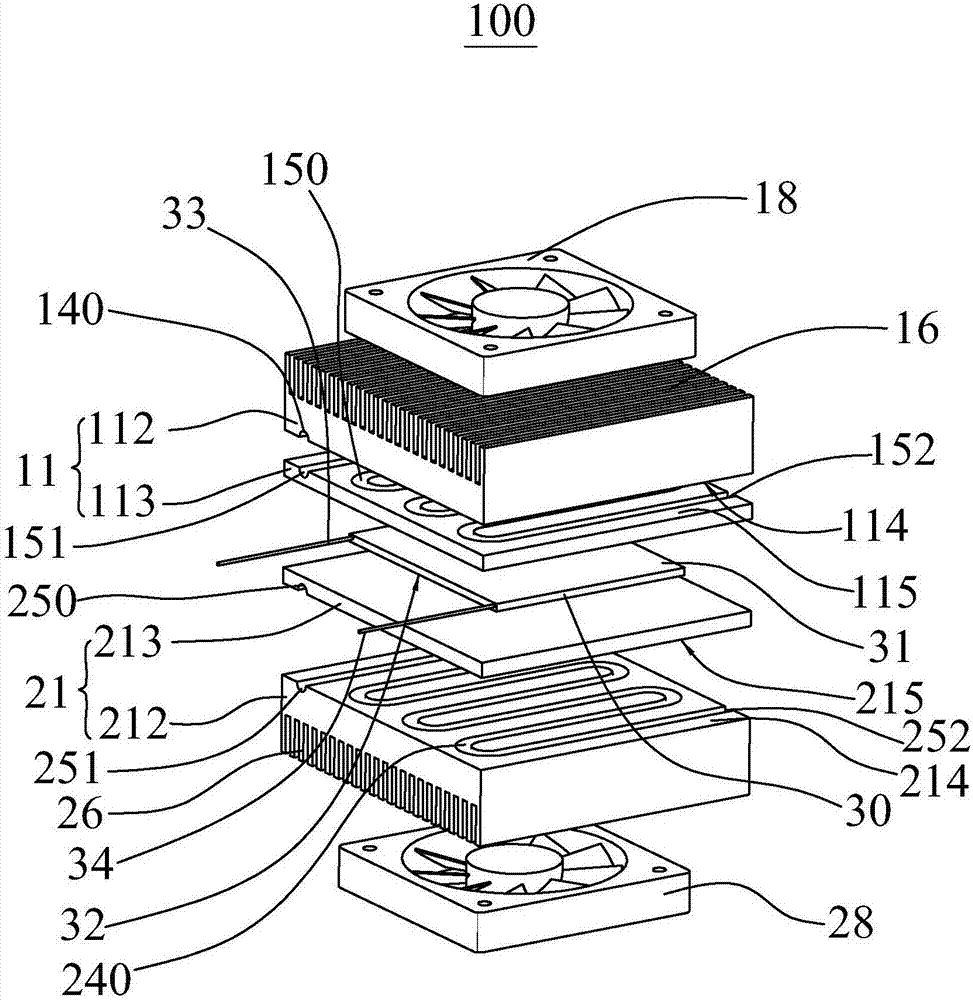

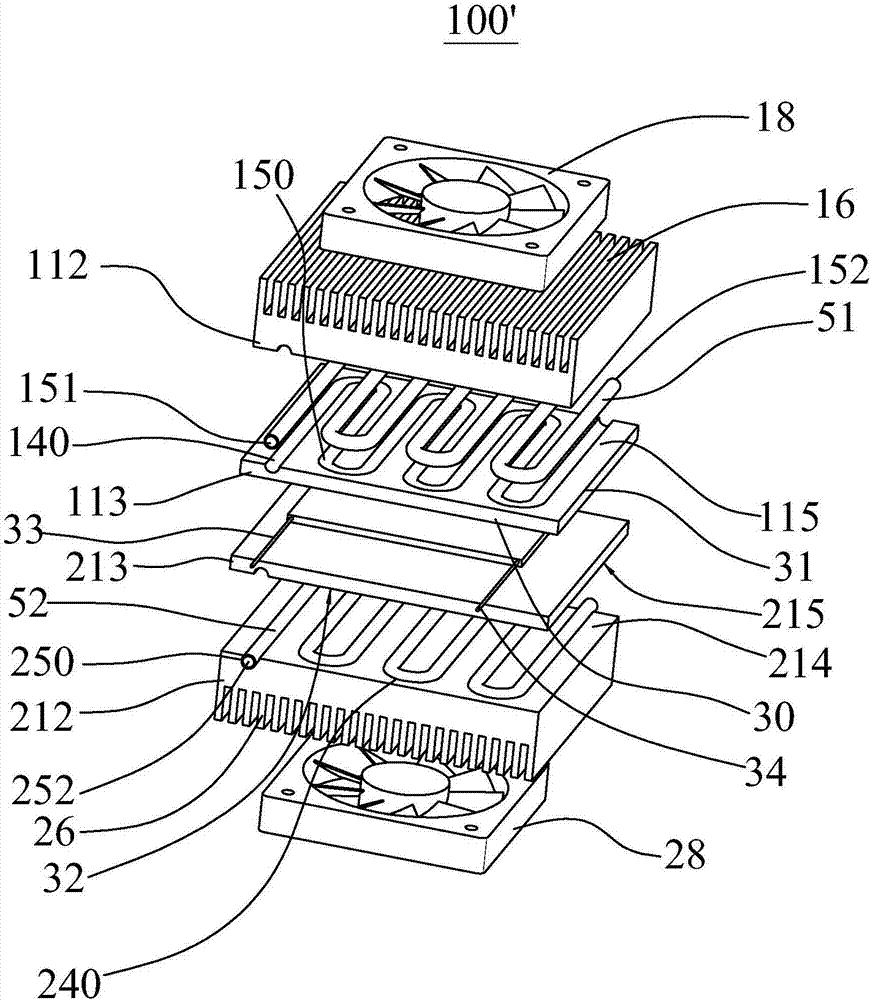

[0023] See figure 1 with figure 2 , Showing a flow channel gas temperature regulator 100 of the first embodiment of the present invention, including a hot-end radiator 10, a cold-end radiator 20, and a semiconductor refrigerator located between the hot-end radiator 10 and the cold-end radiator 20 30. The hot-end heat sink 10 has a hot-end heat dissipation base 11, the cold-end heat sink 20 has a cold-end heat dissipation base 21, and the hot-end heat dissipation base 11 is provided with a hot-end gas flow channel 15, and the cold The end heat sink base 21 is provided with a cold end gas flow passage 25, the hot end gas flow passage 15 has a hot end gas inlet 151 and a hot end gas outlet 152, and the cold end gas flow passage 25 has a cold end gas inlet 251 and The cold end gas outlet 252, the hot end gas outlet 152 and the cold end gas outlet 252 are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com