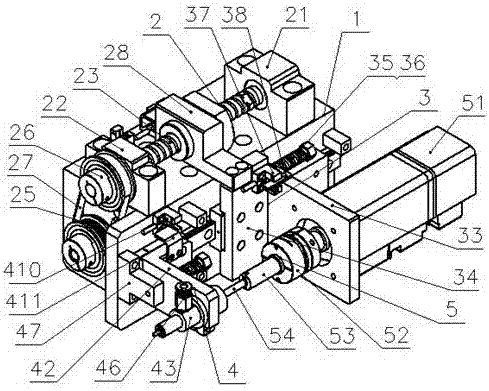

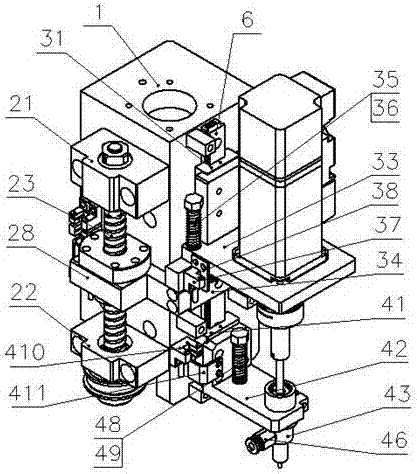

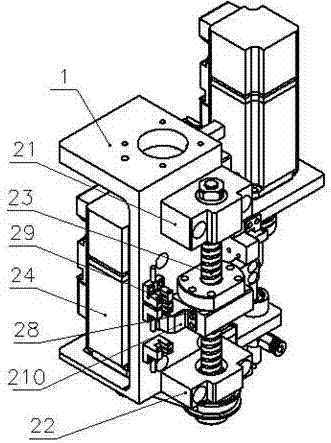

Full-automatic screw locking device

A screw-locking, fully automatic technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inconsistent screw installation torque, damage to workpiece screw holes, over-tightening and sliding teeth, etc., to save positioning time , cost saving and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0049] First, the lifting mechanism lowers the screw suction nozzle mechanism and the screw tightening mechanism along the linear guide rail, the screw suction nozzle mechanism absorbs the screws, and the lifting device raises the screw suction nozzle mechanism and the screw tightening mechanism along the linear guide rail; the base is transferred to the position where the screws need to be installed ; The lifting mechanism lowers the screw suction nozzle mechanism and the screw tightening mechanism along the linear guide rail, the screw suction nozzle mechanism loosens the screws, and the screw tightening mechanism tightens the screws to complete the screw tightening process.

[0050] The limit protection device can protect the position of the suction nozzle mechanism during the process of rising and falling, so as to avoid damage to the screw suction mechanism if it is too high or too low; the overload buffer protection device plays a buffer role to avoid emergency stop during...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com