An electrolysis device and its application in microbubble drag reduction technology

A micro-bubble and technical technology, applied in transportation and packaging, hull, ship construction, etc., can solve the problems of high production and maintenance costs, complicated drag reduction methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

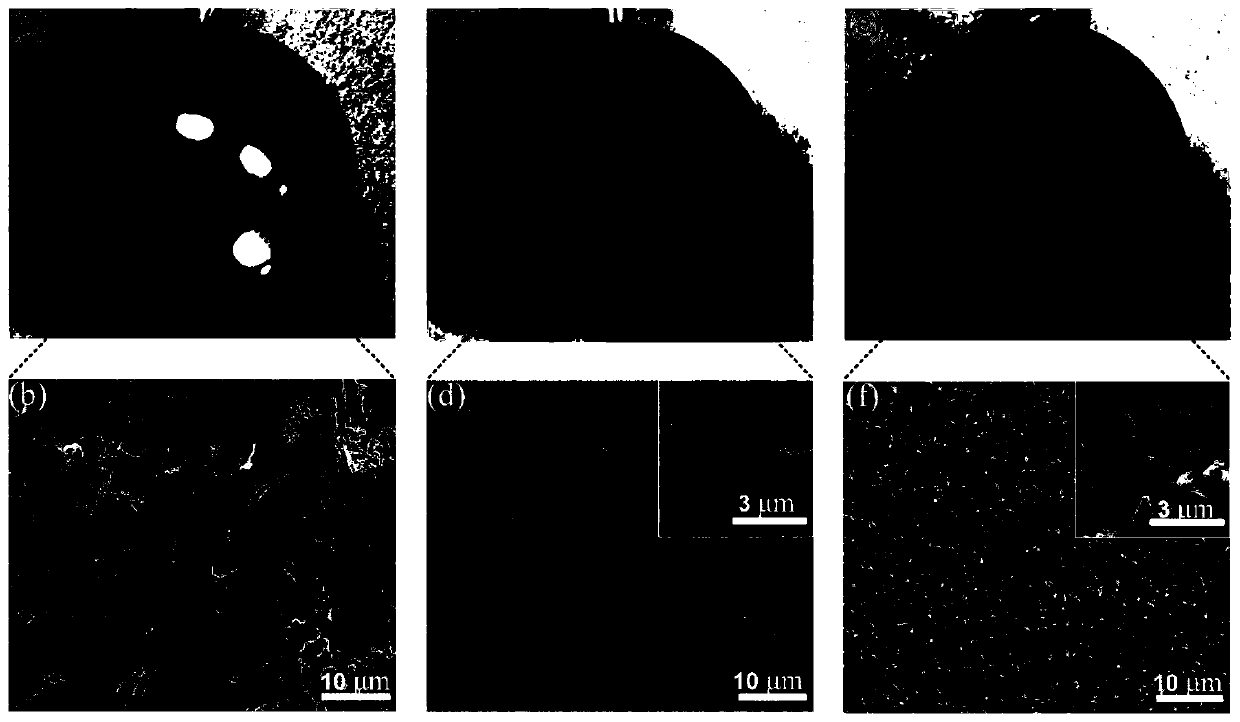

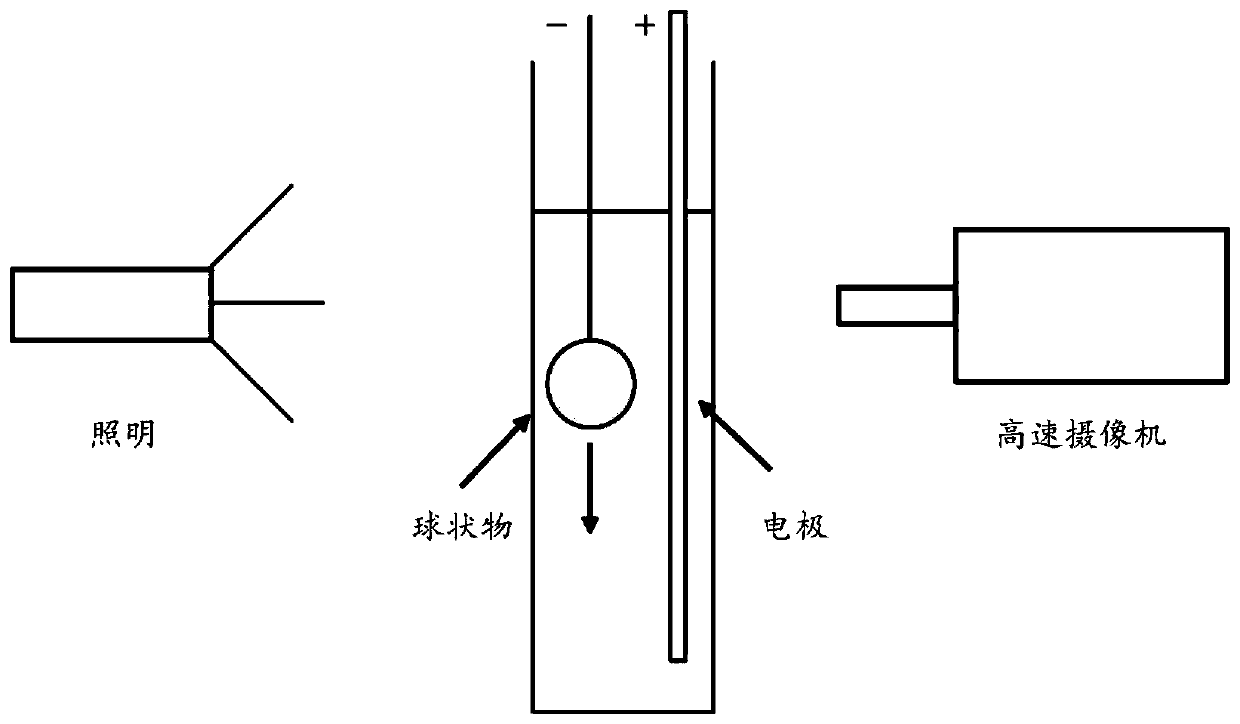

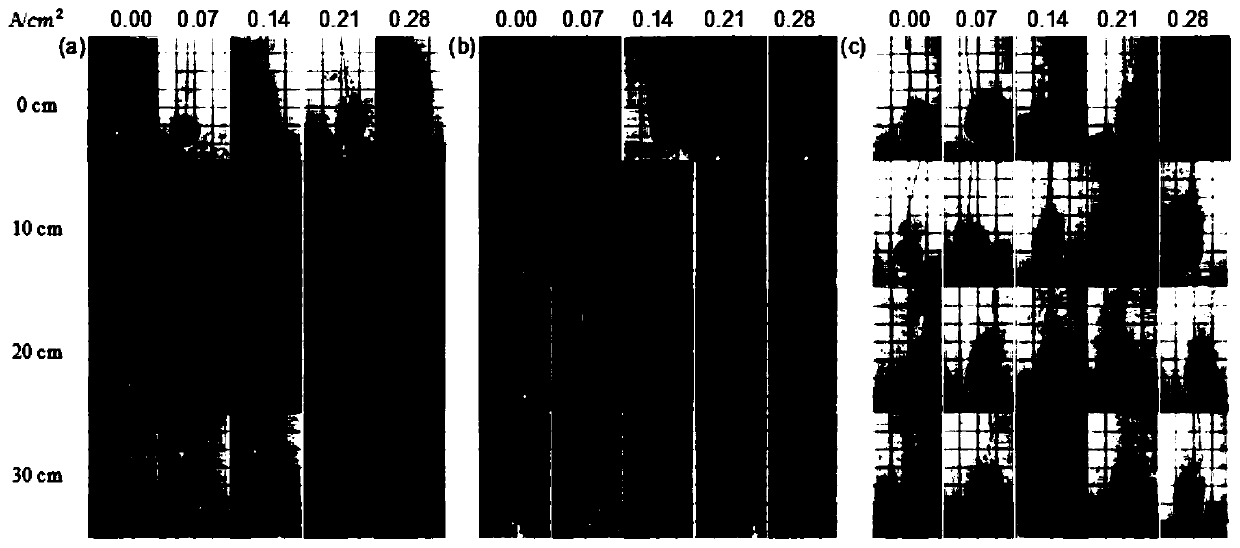

Image

Examples

Embodiment 1

[0048] Drill a hole in the center of the 15mm diameter brass ball, the hole is about 2mm in diameter and about 7mm in depth. Use 600-mesh sandpaper to fully polish one end of the enamelled copper wire with two diameters of thick and thin, so that the copper wire slightly larger than the depth of the first step is exposed. Use 2mol / L sodium hydroxide solution, 2mol / L Hydrochloric acid solution and acetone ultrasonically clean the surface of the brass ball and the exposed copper wire, then clean it with absolute ethanol, finally clean it with deionized water, and dry it for later use. Cut a section of conductive double-sided tape, the length and width are 6×8mm. Tightly wrap half of the conductive double-sided adhesive on the tip of the thick copper wire, and then tightly wrap the thin copper wire on the tip of the copper wire with the conductive double-sided adhesive; insert the thick copper wire wrapped with double-sided adhesive into the brass ball In the hole, keep a thick ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com