Underwater drag-reducing coating and preparation method thereof

A coating and resin-based technology, applied in the field of preparation of underwater drag-reducing coatings, can solve the problems of high production and maintenance costs, low drag reduction rate, etc., achieve low production costs and maintenance costs, and reduce drag effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

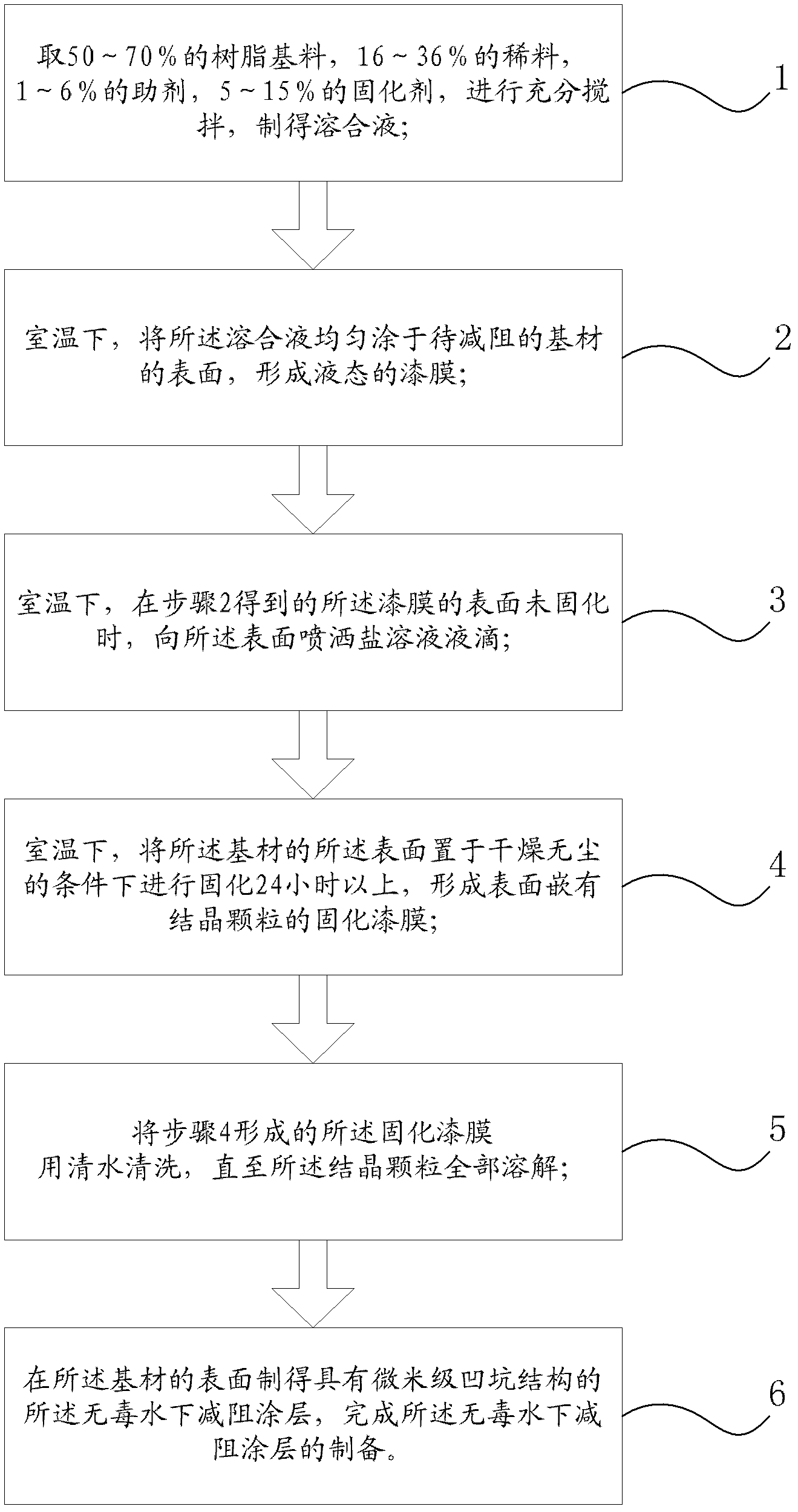

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: According to a kind of underwater drag-reducing coating of the present invention, comprise epoxy resin, thinner, auxiliary agent, curing agent, each component is respectively by weight percentage: epoxy resin 70%, thinner 20%, auxiliary Agent 5%, curing agent 5%. The underwater drag-reducing coating of this embodiment, after being placed on the surface of the substrate by the preparation method of the present invention, has a micron-scale pit structure on the surface, which has a good drag-reducing effect and can achieve the purpose of the present invention.

Embodiment 2

[0027] Embodiment 2: Another underwater drag-reducing coating of the present invention, including polyurethane resin, thinner, auxiliary agent, fat-soluble luminous powder, curing agent, each component is respectively by weight percentage: polyurethane resin 65%, thinner 19% %, auxiliary agent 6%, curing agent 10%. The underwater drag-reducing coating of this embodiment also has a good drag-reducing effect after being placed on the surface of the substrate by the preparation method of the present invention, and can achieve the purpose of the present invention.

Embodiment 3

[0028] Embodiment 3: Another underwater drag-reducing coating of the present invention, including silicone resin, thinner, auxiliary agent, fat-soluble luminous powder, curing agent, each component is respectively by weight percentage: silicone resin 60%, Thinner 25%, auxiliary agent 3%, curing agent 12%. The underwater drag-reducing coating of this embodiment, after being placed on the surface of the substrate by the preparation method of the present invention, also has a good drag-reducing effect, and can also achieve the purpose of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com