Hot surface cavitation efficiency-increasing and resistance-reducing test device and method

The technology of a test device and test method is applied in the field of hot surface cavitation synergistic drag reduction test device, which can solve the problems of poor continuous drag reduction effect, inability to realize stable attachment of microbubbles, and high energy consumption, and achieve low cost, Simple operation and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

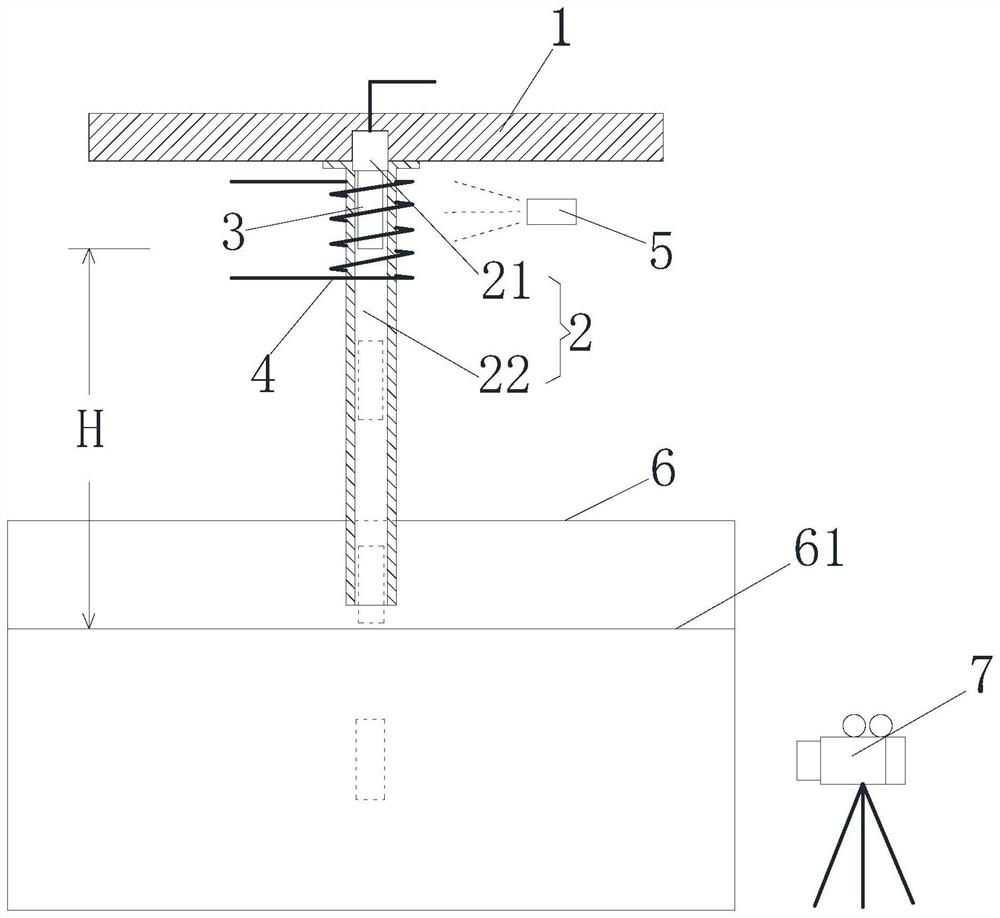

[0043] like figure 1 As shown, a thermal surface cavitation efficiency and drag reduction test device includes a test bench 1 , a transmitter 2 , a metal body 3 , a heater 4 , a thermometer 5 , a water tank 6 and a photographing device 7 . Wherein, the test table 1 may be a fixed table set fixedly, and may also be a movable table whose height can be adjusted up and down. The test bench 1 includes, but is not limited to, a transmitter 2 installed with a metal body 3 detachably and vertically connected. In addition, the number of transmitters 2 can be increased as required and arranged at intervals.

[0044] like figure 1As shown, in one specific embodiment, the transmitter 2 includes an electromagnet 21 and a conduit 22 . The upper end of the guide tube 22 is connected to the test stand 1 , and is provided with an electromagnet 21 for attracting the transmitter 2 . Specifically, the upper end of the conduit 22 and the upper end of the electromagnet 21 are both vertically and...

Embodiment 2

[0073] like Figure 1 to Figure 8 As shown, in this specific embodiment, a thermal surface cavitation synergistic drag reduction test device, compared with the thermal surface cavitation synergy drag reduction test device described in the first embodiment, also includes a pick-and-place device. , the pick-and-place device mainly includes a two-dimensional sliding table structure 81 , a collection tray 82 and a lifting device 83 .

[0074] like Figure 8 As shown, specifically, the test bench 1 is provided with an ejection opening 11 and an ejection opening 12 , and a conduit 22 is arranged at the lower port of the ejection opening 12 . The electromagnet 21 is disposed on the test stand 1 through the two-dimensional sliding table structure 81 so as to be able to move back and forth between the cartridge taking port 11 and the cartridge discharging port 12 . The two-dimensional sliding table structure 81 includes, but is not limited to, it is mainly composed of a first electri...

Embodiment 3

[0078] like Figure 1 to Figure 10 As shown, in this specific embodiment, a thermal surface cavitation synergy and drag reduction test device, compared with the thermal surface cavitation synergy and drag reduction test device described in the second embodiment, the test bench passes the swing mechanism. It is arranged above the water tank in a swingable and adjustable manner, and is used to change the water entry angle of the metal body, so as to facilitate the study of the oblique injection of the metal body into the water.

[0079] like Figure 1 to Figure 10 As shown, specifically, the swing mechanism includes but is not limited to a connecting arm 91, a swing arm 92, a linkage shaft 93 and a drive motor 94, the left and right ends of the test bench 1 are provided with swing arms 92, and the other end of the swing arm 92 is pivotally connected There are connecting arms 91 connected to the fixed surface. The two swing arms 92 are connected to each other through a linkage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com