A method for automatic docking trajectory planning of a launch vehicle bleeder connector

A launch vehicle and trajectory planning technology, which is applied in transportation and packaging, space navigation equipment, space navigation ground equipment, etc. It can solve the problems of increasing the difficulty of automatic docking control, eliminate the risk of collision, and ensure rapidity and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

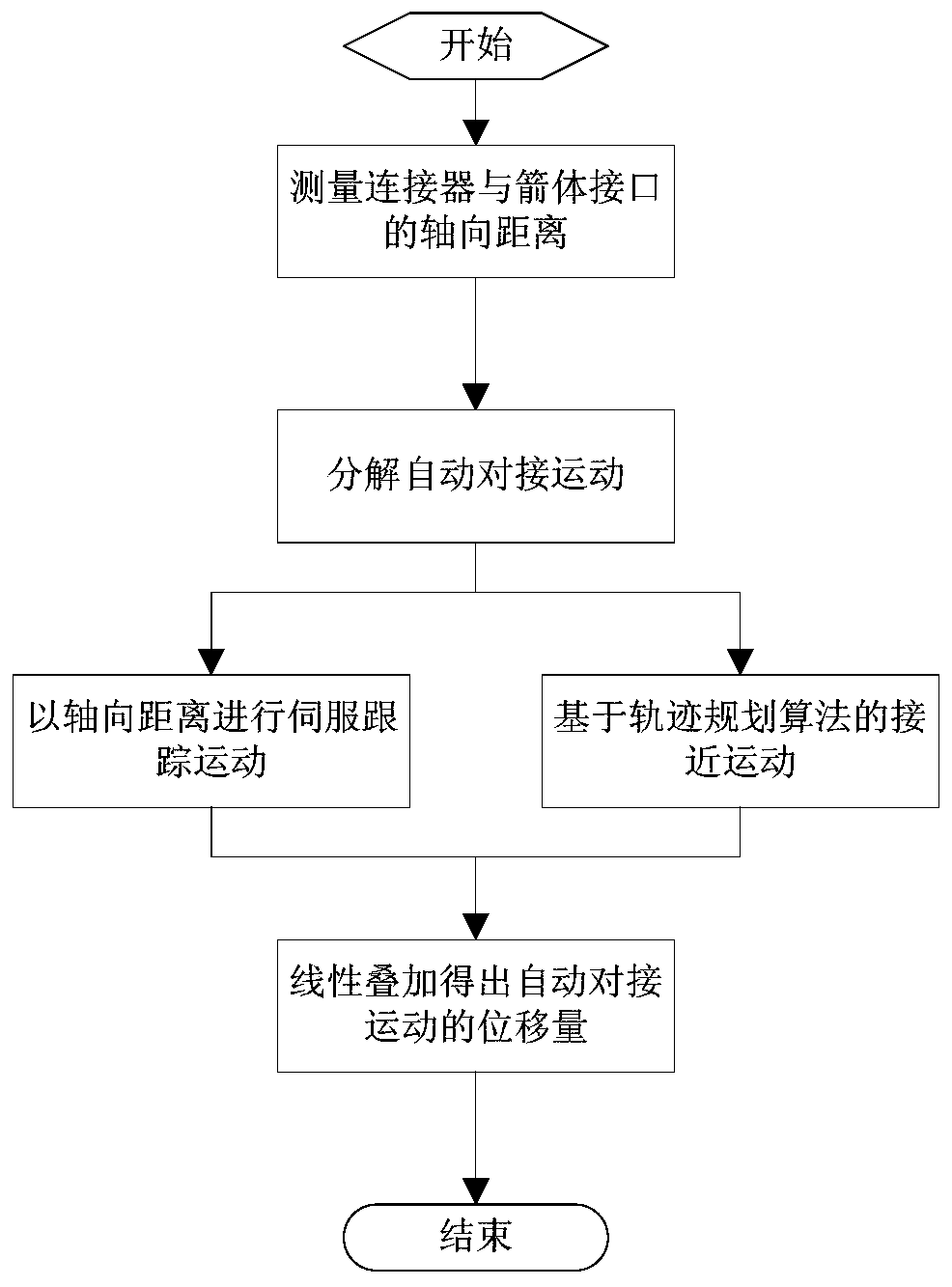

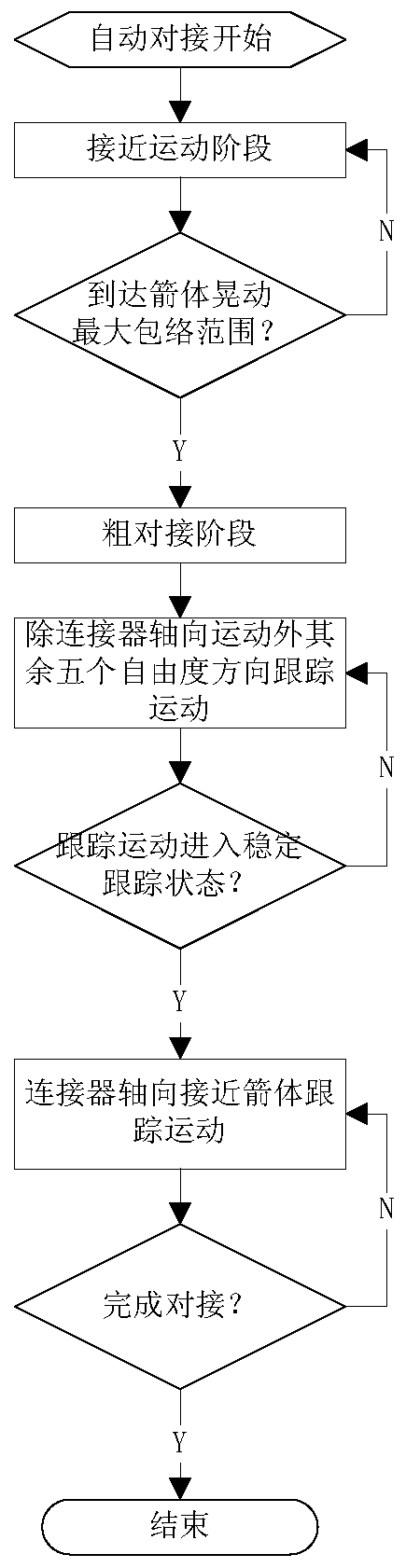

[0034] An automatic docking trajectory planning method for a carrier rocket loading and releasing connector according to the present invention divides the automatic docking process into three stages, which are respectively the approaching motion stage, the rough docking stage, and the fine docking stage, and then describes the automatic docking motion in the fine docking stage as The servo tracking motion of the randomly measurable target, and the method of linear superposition is used to divide the automatic docking motion into two parts: one is the servo tracking motion of the venting connector and the propellant filling port of the rocket body at a known distance, and the other is the servo tracking motion at a known distance. It is the approach motion based on the trajectory planning algorithm of the filling and venting connector and the propellant filling port of the rocket body. The control algorithm is designed for the two parts of the motion respectively, and the displac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com