Forming process for novel environment-friendly energy-saving and disassembly-free house

An environmentally friendly, energy-saving, molding process technology, applied in building types, residential buildings, mold shells/templates/work frames, etc., can solve problems such as affecting the health of users, consuming a lot of manpower and time, and being disorderly, to meet the differences The effect of optimizing production and use requirements and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The invention discloses a molding process of a novel environment-friendly and energy-saving house without dismantling. The molding process includes the following steps:

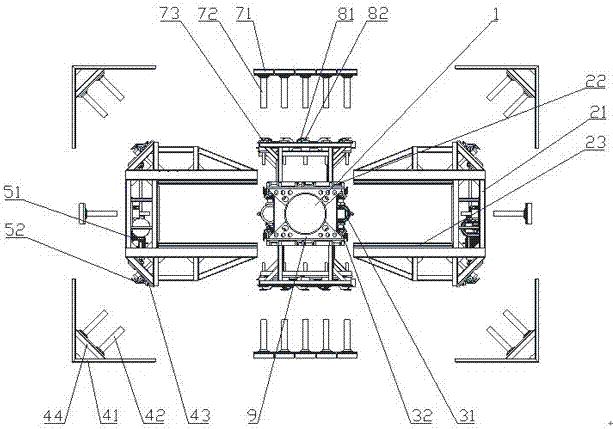

[0059] (1) Expansion forming mold: According to the specified size of the production tank, the expansion and opening of the tank forming mold is completed, and the second drive motor 51 drives the second screw lifter 52 to move, so that the screw end of the second screw lifter 52 will be supported at a right angle. The frame 41 is pushed back, and the first drive motor 31 drives the first screw lifter 32 to move, so that the screw end of the first screw lifter 31 pushes the module frame 21 back;

[0060] (2) Gap compensation of the forming mold after expansion: Since the module frame 21 and the right-angle support frame 41 are pushed apart, there will be a gap between the right-angle support frames 41, and the gap compensation module 7 is used for gap compensation, and the third drive The motor 81 driv...

Embodiment 2

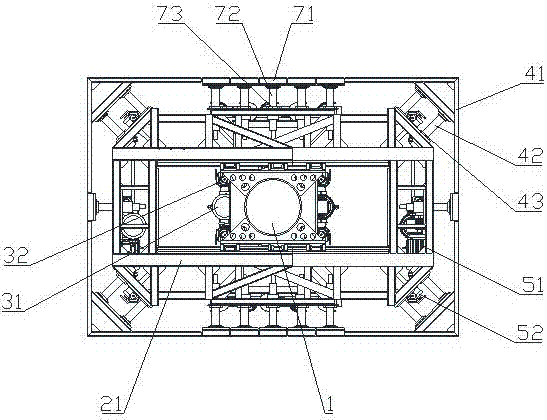

[0072] Different from Example 1, as Figure 4 As shown, three groups of clearance compensation blocks 71, a second guide rod 72 and a second guide sleeve 73 are respectively provided on the upper and lower sides of the mold main shaft 1 in this embodiment, and a group of clearance compensation blocks 71, second guide sleeves 73 are respectively provided on the left and right sides of the main shaft 1. The guide rod 72 and the second guide sleeve 73 form a rectangular profile on the side after the mold is expanded, so that the non-demolition house with a rectangular cross section can be produced. The size of the non-demolition house is: length 9m, width 3.6m, height 3m.

Embodiment 3

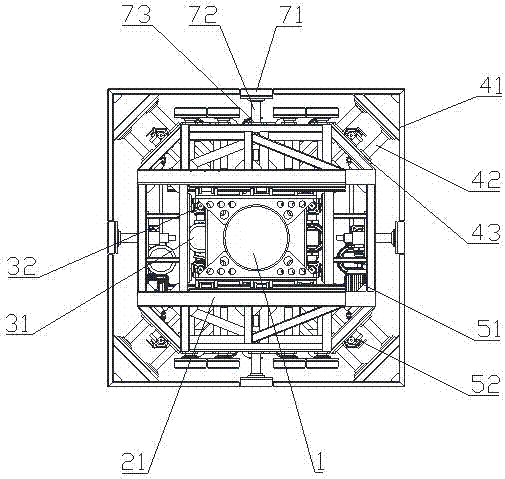

[0074] Different from Examples 1 and 2, as Figure 5 As shown, five sets of gap compensation blocks 71, a second guide rod 72, and a second guide sleeve 73 are provided on the upper and lower sides of the mold spindle 1 in this embodiment, and a set of gap compensation blocks 71, a second guide sleeve 73 are respectively provided on the left and right sides of the main shaft 1. Two guide rods 72 and the second guide sleeve 73 form a rectangular profile on the side after the mold is expanded, so that a rectangular cross-section can be produced without dismantling the house. The size of the dismantling-free house is: length 9m, width 4.2m, height 3m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com