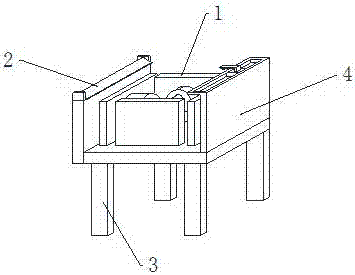

Diamond cutting line detection clamp

A technology of diamond cutting wire and detection fixture, which is applied in the field of diamond processing, can solve the problems of reducing the service life of the fixture, corrosion of the fixture, and increasing the workload of the staff, so as to avoid damage, increase labor, and facilitate installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

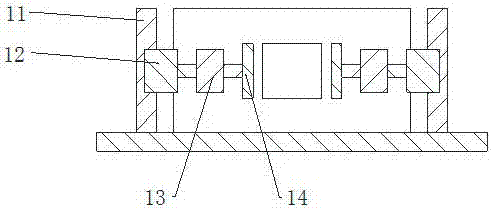

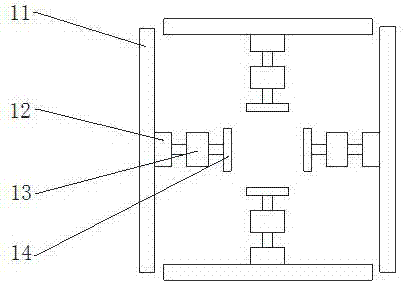

[0029]Specific embodiments: when using the present invention, the staff first turns on the lighting lamp 46, and the lighting lamp 46 starts to emit light, and then the staff pushes the slider 42, and the slider 42 moves forward under the action of the ball, and the slider 42 moves forward Drive the fixed frame 44 to move forward, the fixed frame 44 moves forward to drive the universal head 45 to move forward, the universal head 45 moves forward to drive the lighting lamp 46 to move forward, until the lighting lamp 46 moves to a suitable position, the staff stops Push the slider 42, and then the staff starts the electric telescopic rod 2 43, and the electric telescopic rod 2 43 works and expands outwards until the right end of the electric telescopic rod 2 43 contacts with the inner left wall of the chute, and the slider 42 is fixed on the chute Inside, the staff closes the electric telescopic rod 2 43, which is designed to facilitate the adjustment of the position of the light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com