Full-automatic duck feather removing system and duck feather removing method

A fully automatic, duck feather technology, applied in poultry plucking machines, slaughtering, poultry processing, etc., can solve the problem of consuming a lot of manpower and material resources, achieve the effect of low labor cost and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to have a further understanding of the technical solutions and beneficial effects of the present invention, the technical solutions of the present invention and the beneficial effects produced are described in detail below in conjunction with the accompanying drawings.

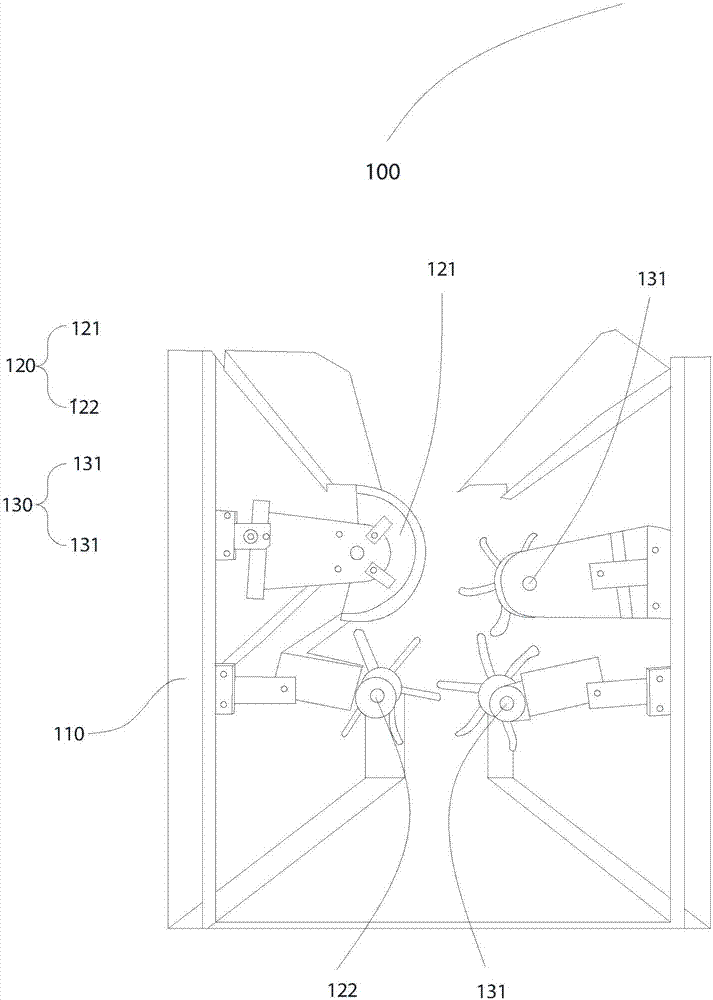

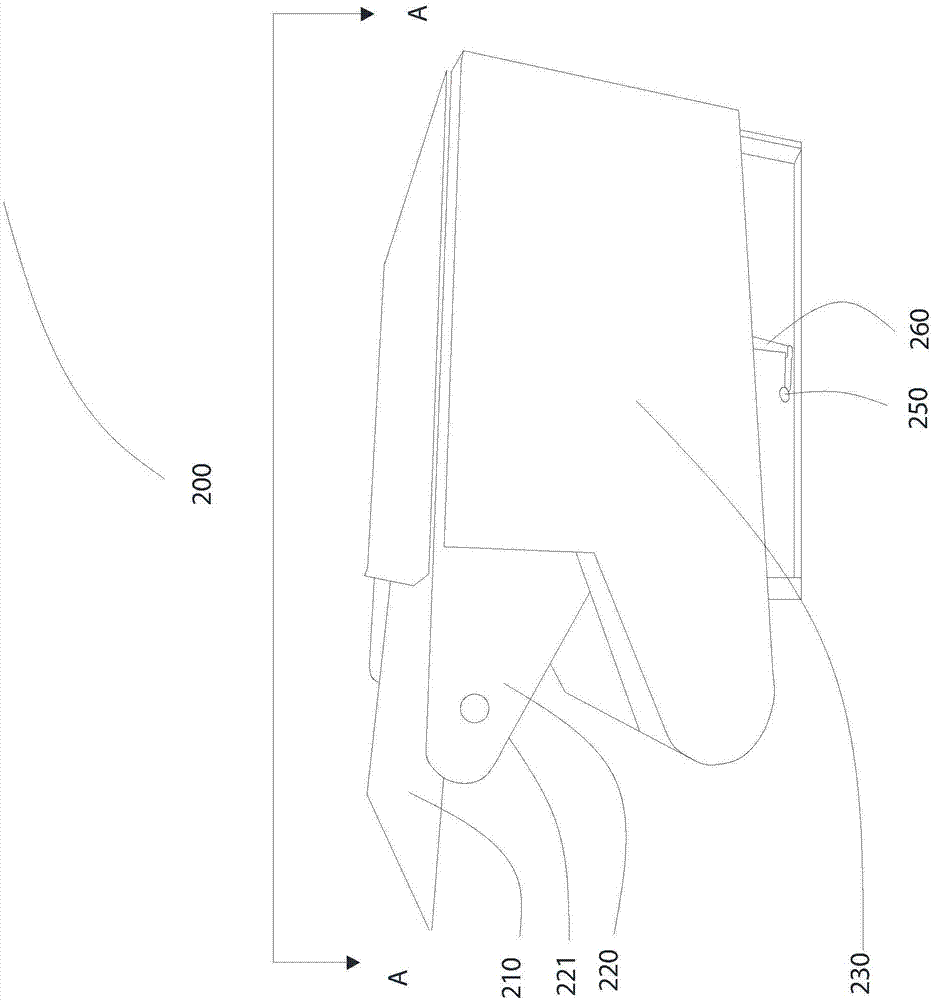

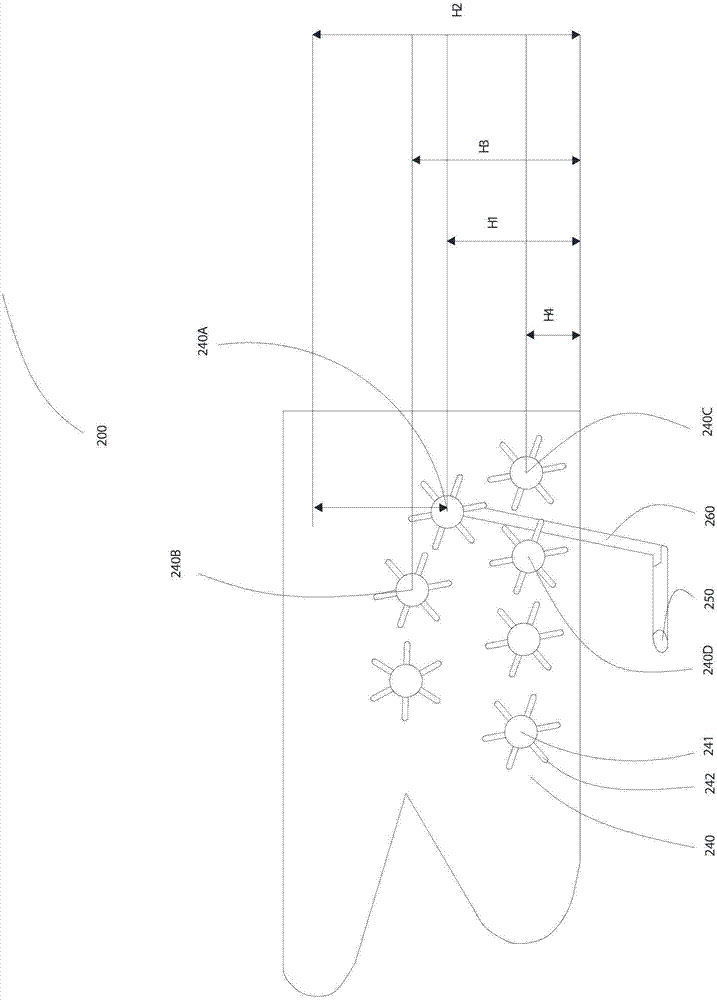

[0061] figure 1 , figure 2 and Figure 4 They are respectively the three-dimensional structural schematic diagrams of the vertical depilatory machine and the horizontal depilatory machine and the front view structural schematic diagrams of the wax dipping device in an embodiment of the present invention, such as Figure 1-Figure 2 and Figure 4As shown, the present invention provides a fully automatic duck feather removal system, comprising a vertical hair remover 100, a horizontal hair remover 200 and a wax dipping device 300, wherein the vertical hair remover 100 is used to remove hair first in ducks Complete the depilation of the back and neck of the duck. During specific work, the duck ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com