Rotary clamping assembly

A technology of clamping components and rotary shafts, which is applied in the direction of clamping devices, clamping, metal processing machinery parts, etc., can solve problems affecting the accuracy of the center hole, affecting work efficiency, and affecting accuracy, so as to ensure processing accuracy and clamping Good effect and high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

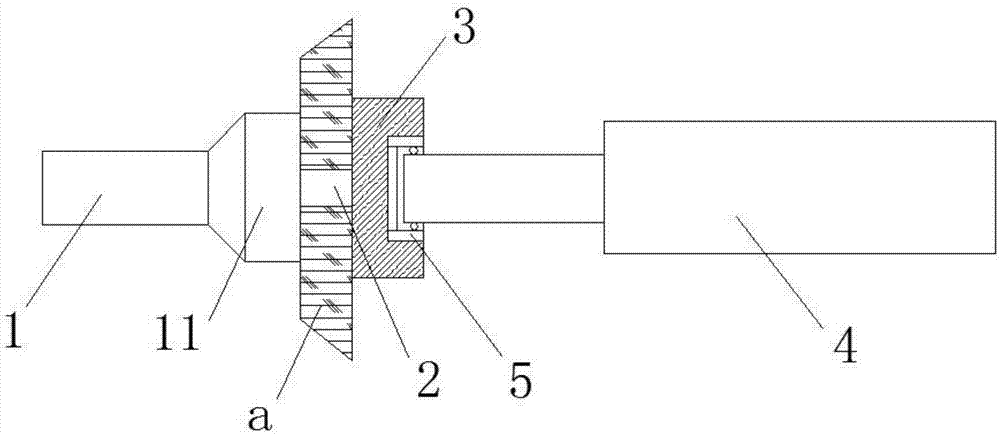

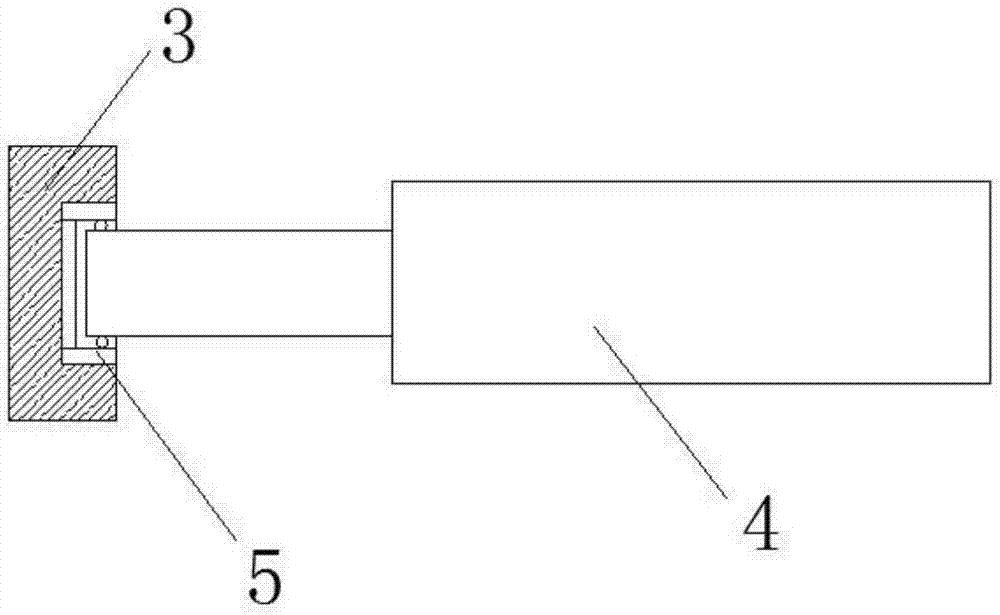

[0022] see figure 1 , figure 1 It is a structural schematic diagram of the rotary clamping assembly of the present invention. The rotary clamping assembly of the present invention includes a rotary shaft 1, a fixing member 2, a pressing block 3 and a pressing cylinder 4; the fixing member 2 is fixed on the rotating shaft 1 and is used to fix the workpiece a; the pressing The compression cylinder 4 is arranged coaxially with the rotary shaft 1, and the piston rod of the compression cylinder 4 faces the rotary shaft 1; the compression block 3 is fixed on the piston of the compression cylinder 4 through a bearing 5 On the rod, there is a gap between the pressing block 3 and the fixing piece 2 .

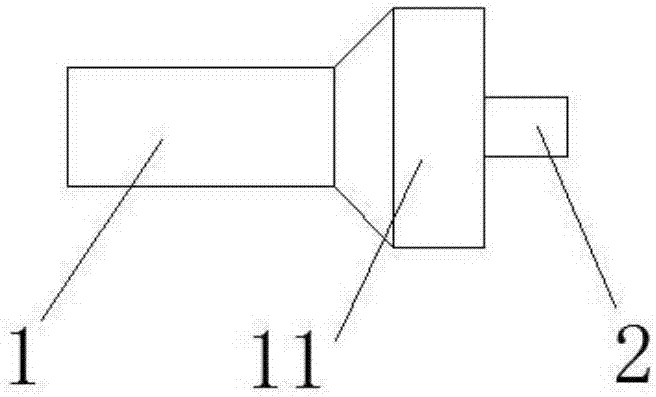

[0023] Specifically, see figure 2 , figure 2 It is a schematic diagram of the structure of the rotary shaft 1 and the fixed part 2. In this embodiment, a fixing part 11 is preferably provided at the end of the rotating shaft 1, the diameter of the fixing part 11 is larger than the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com