Picking manipulator on picking equipment

A technology of manipulator and equipment, applied in the direction of pickers, manipulators, agricultural machinery and implements, etc., can solve problems such as damage to fruit trees, waste of time, and difficulty in picking fruits, and achieve the effect of reducing damage and avoiding multiple movements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

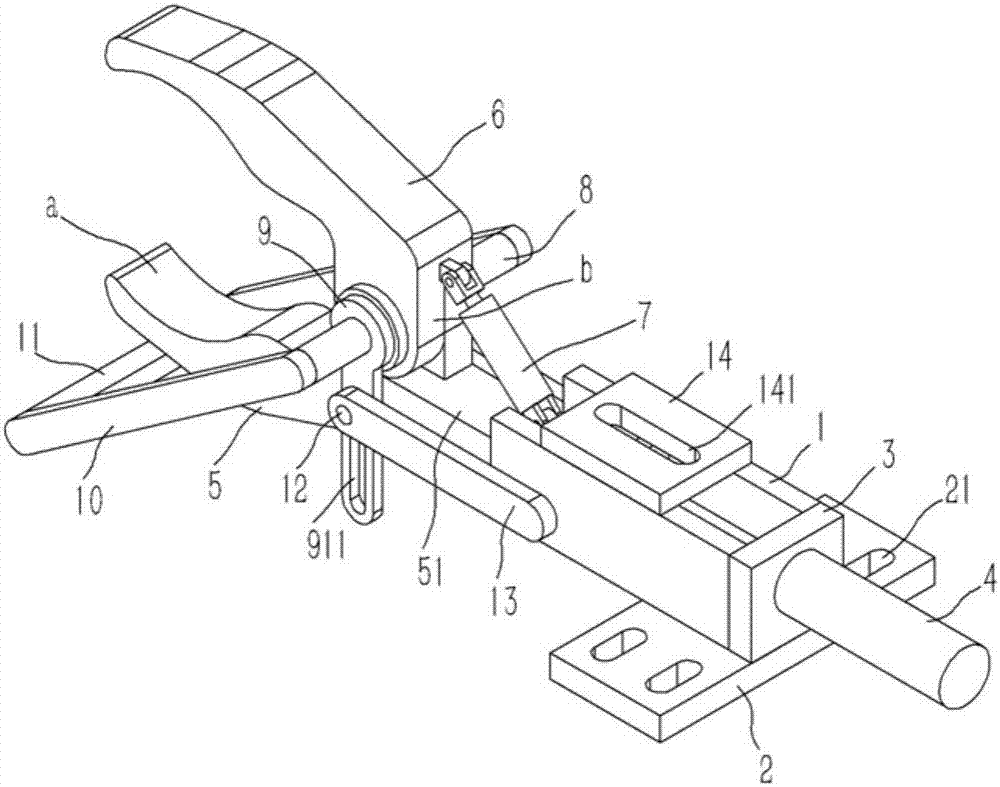

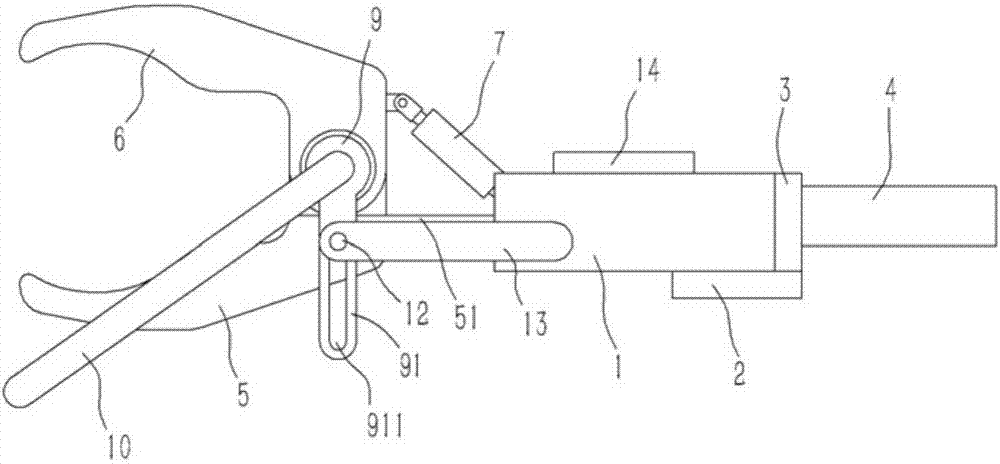

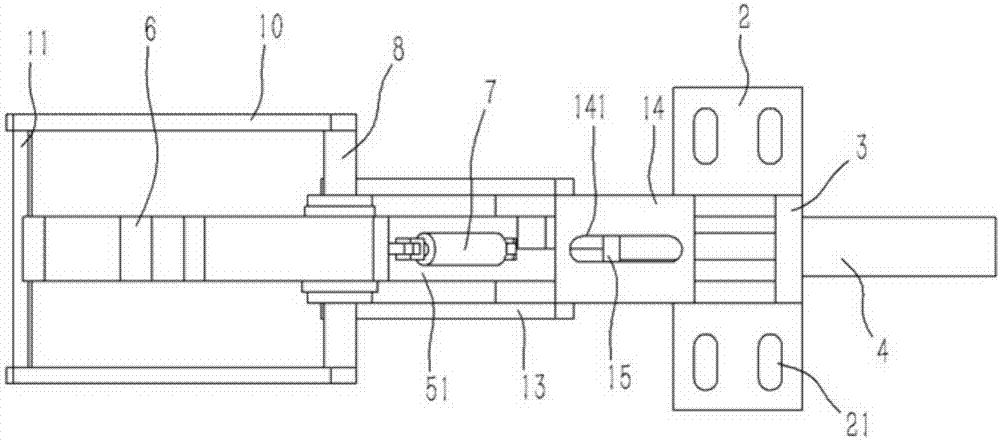

[0018] Such as Figure 1-5 As shown, the picking manipulator on the picking equipment includes a C-shaped groove rail 1, a baffle plate 3 is fixed on the rear end surface of the groove rail 1, the bottom surface of the rear end of the groove rail 1 is fixed on the bottom plate 2, and the bottom plates on both sides of the groove rail 1 There are several installation holes 21 formed on the 2, and the front side of the groove rail 1 is provided with the opposite first jaw 5 and the second jaw 6, and the first jaw 5 or the second jaw 6 are formed by arc-shaped jaws a and an L-shaped hinge part b, the hinge part b of the first jaw 5 and the hinge part b of the second jaw 6 are hinged through the hinge shaft, and the hinge between the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com