Scraping and finishing device for Nixing pottery processing

A trimming device and the technology of Nixing pottery, which is applied in the direction of manufacturing tools and ceramic molding machines, etc., can solve the problems of poor scraping effect and single structure of scraping blades, and achieve fast scraping, wide applicability and good scraping effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

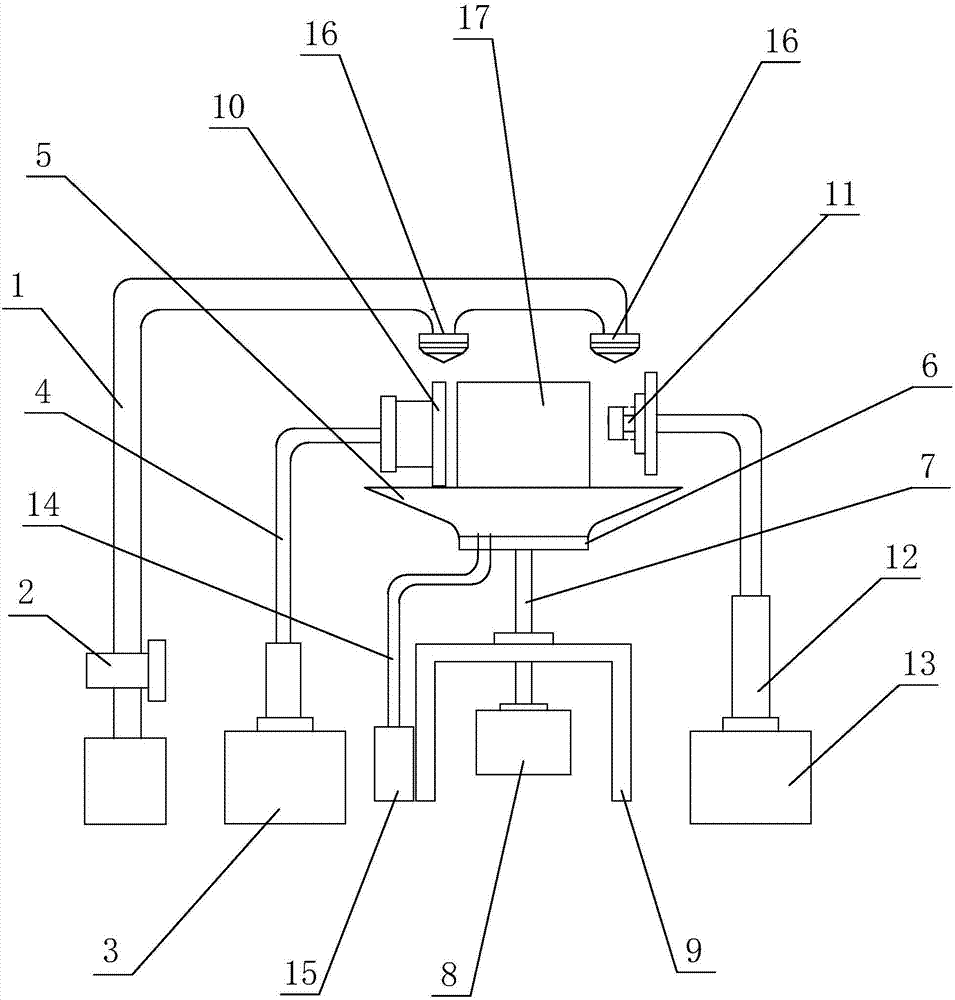

[0021] Such as figure 1 As shown, a scraping and trimming device for Nixing pottery processing includes a placement plate 5, a turntable 6, a support rod 7, a support seat 9, a first motor 8 and first scrapers symmetrically arranged on both sides of the placement plate 5. The edge device and the second edge scraping device, in this embodiment, also include a cleaning device for the scraper blade 10.

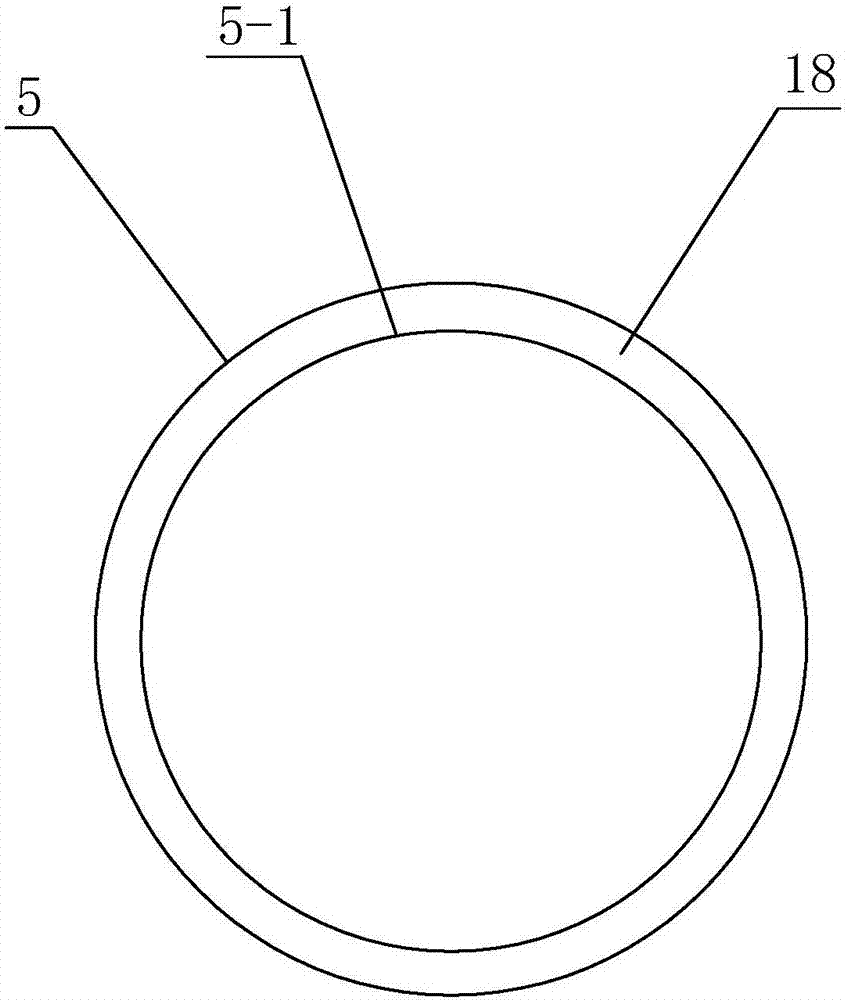

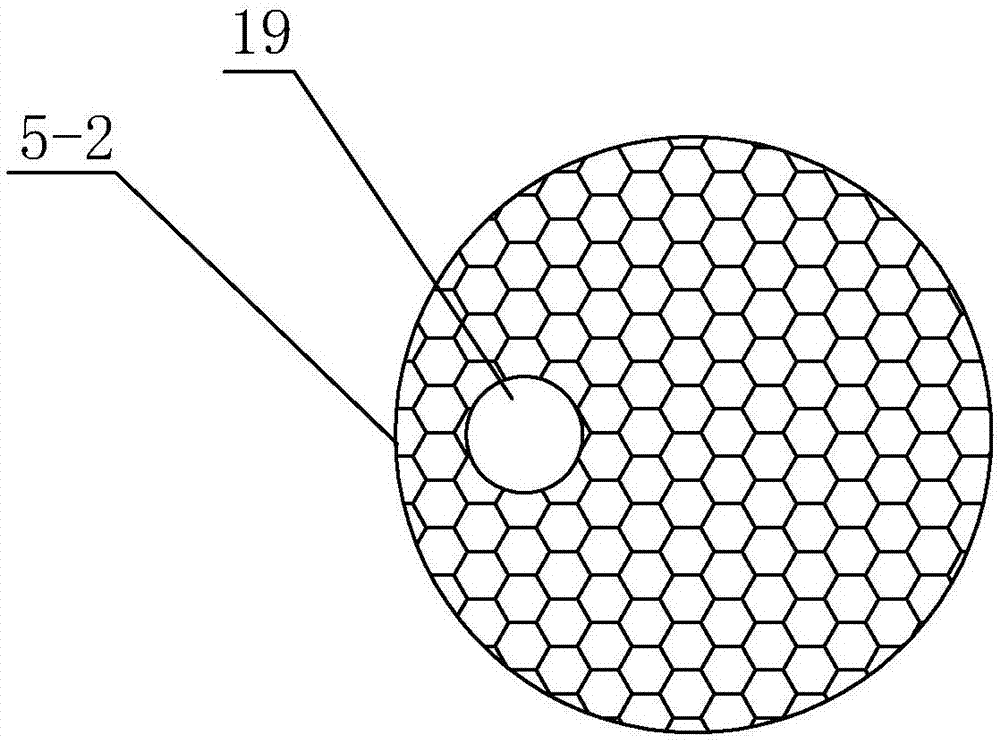

[0022] The placing tray 5 is used to place the main body 17 of Nixing pottery and is installed on the turntable 6 . The turntable 6 is arranged above the support base 9 for driving the placement tray 5 to rotate. One end of the support rod 7 is fixed on the bottom of the turntable 6 , and the other end passes through the support base 9 and is connected to the first motor 8 . In order to facilitate the removal or placement of the Nixing pottery main body 17 from the placement tray 5, the support rod 7 can be designed as a liftable structure. The first motor 8 is used to drive t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com