A non-contact 3D printing consumable state detection method

A 3D printing, non-contact technology, applied in the field of 3D printing, can solve problems such as printing failure, affecting printing quality, exhaustion of consumables, etc., and achieve the effect of avoiding printing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the description of the drawings and specific embodiments.

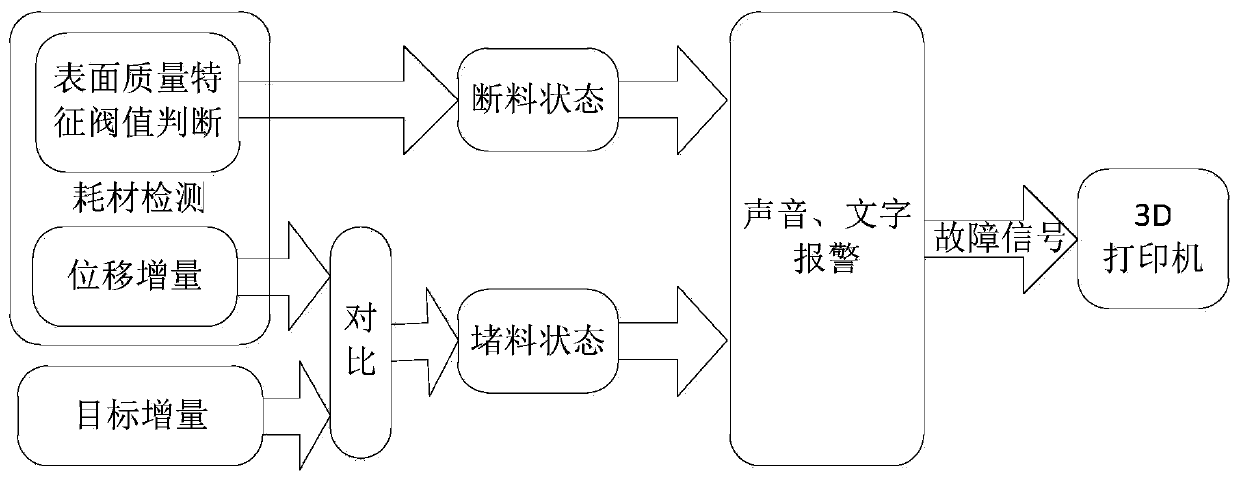

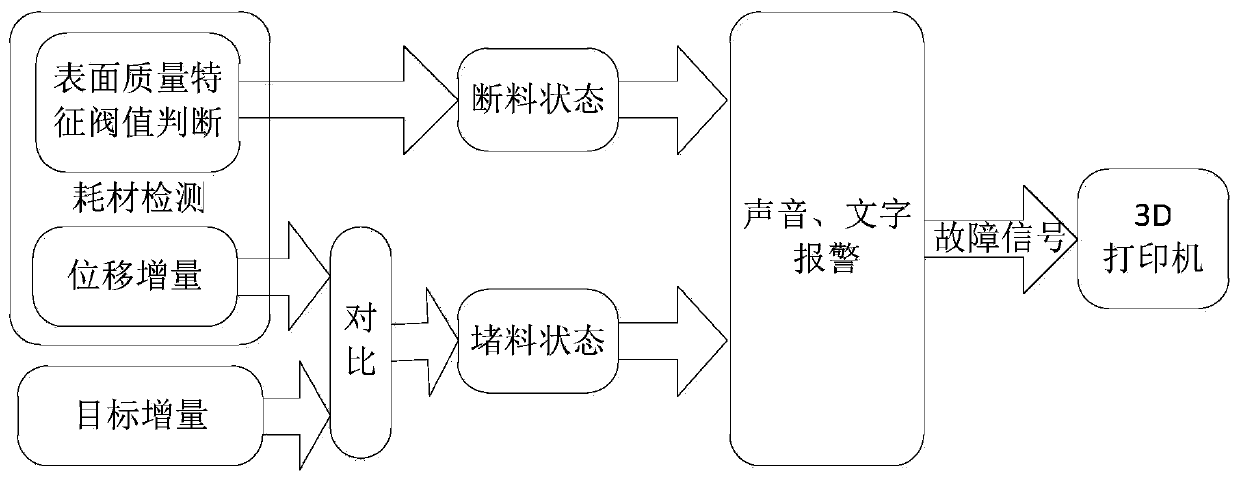

[0015] Such as Figure 1 to Figure 2 As shown, a non-contact 3D printing consumables state detection method comprises the following steps:

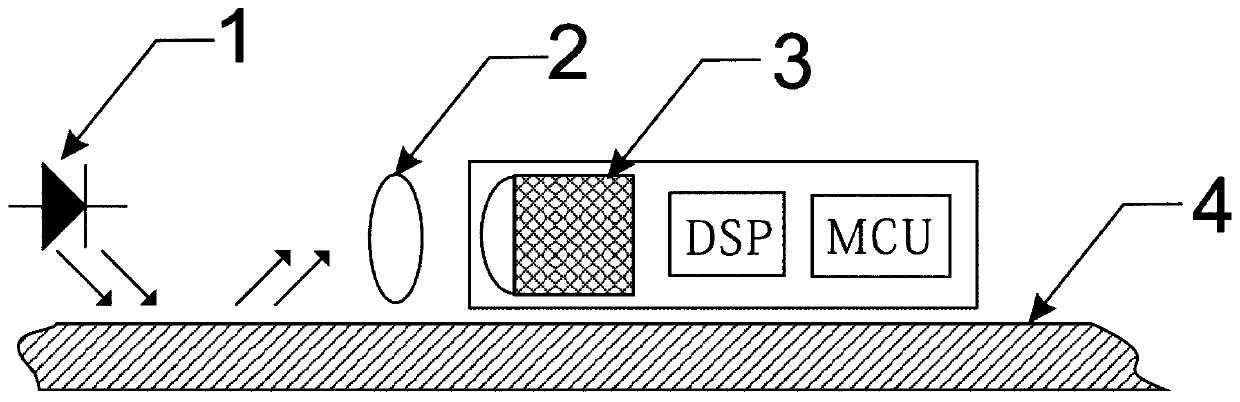

[0016] S1. Inspection of consumables 4 (also known as 3D printing consumables), such as figure 2 As shown, the lighting conditions are provided by the light-emitting diode 1, and the CMOS camera 3 continuously takes pictures of the surface of the consumable 4 through the convex lens 2, and the DSP unit extracts the feature pixels in each picture, and records the number of effective features (also known as surface quality). Index), by comparing the position changes of the same feature pixel in two adjacent photos, calculate the displacement increment of consumable 4 in the time interval between these two photos;

[0017] S2. Judging the status of consumables 4;

[0018] S21. Material broken detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com