Base support component, film-forming device and method

A technology of film forming equipment and film forming method, which is applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problems of high risk, long tangent time, inflexible thickness adjustment, etc., and achieve non-hazardous , faster tangent speed and better working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

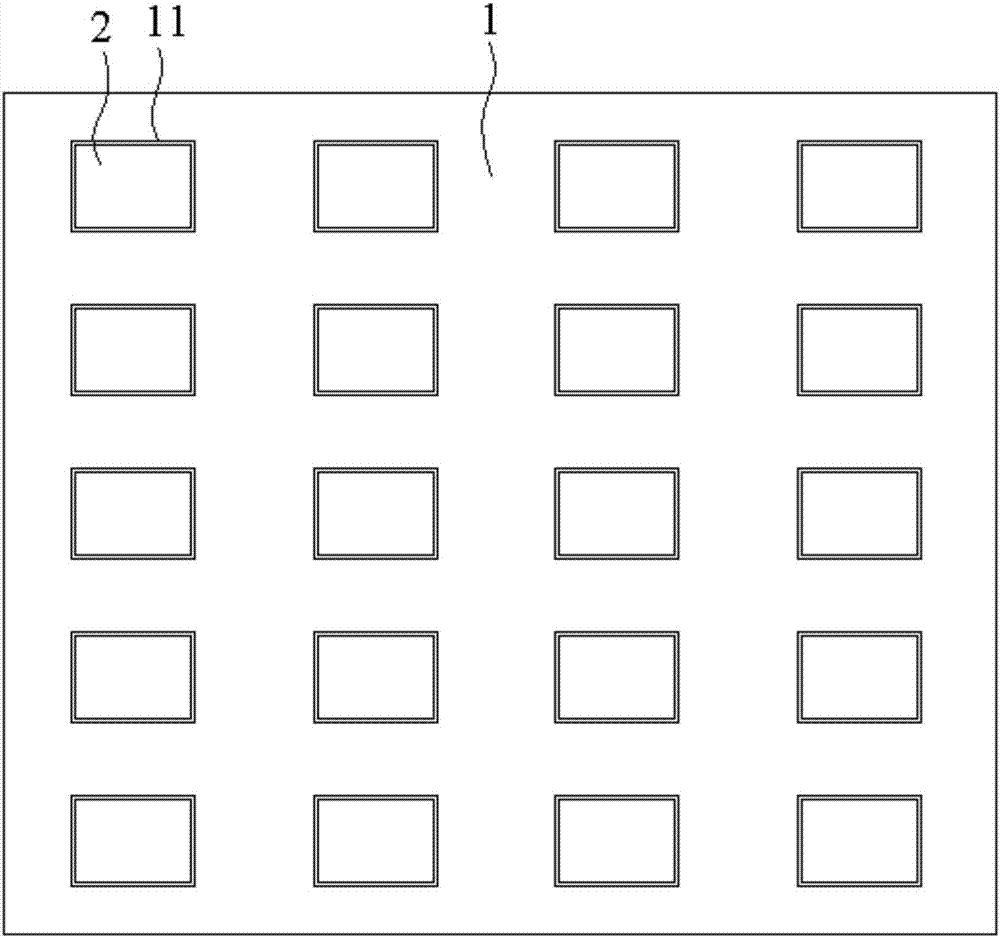

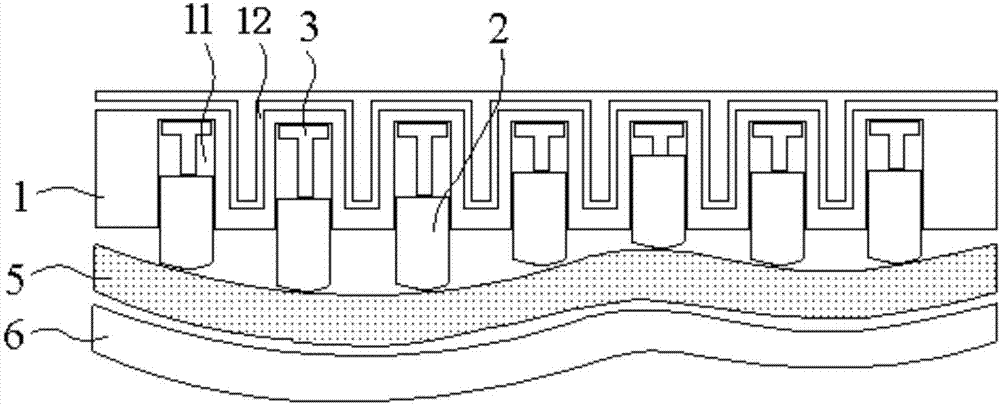

[0043] Such as Figure 2 to Figure 4 As shown, the present embodiment provides a substrate support assembly, which includes a support plate 1 for supporting the substrate 5 in the film forming process, the support plate 1 has a working surface for facing the substrate 5, wherein,

[0044] There are a plurality of openings 11 arranged at intervals on the working surface of the support plate 1, and a movable block 2 and a driver 3 are arranged in each opening 11, and the driver 3 is used to drive the movable block 2 to lift relative to the working surface, so that the movement of the movable block 2 The top surface is at least movable between a position flush with the work surface and a position protruding from the work surface.

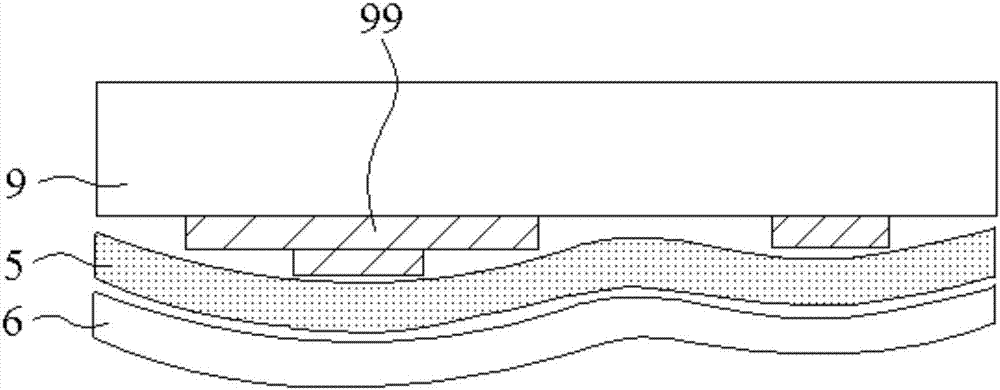

[0045] The substrate support assembly has a support plate 1, which is used to support a substrate 5 in a film forming process such as evaporation; and a mask plate 6 is a mask with a hollow pattern (not shown) for passing a film forming gas. The stenc...

Embodiment 2

[0080] Such as Figure 2 to Figure 4 As shown, the present embodiment provides a film-forming method, which is carried out by using the above-mentioned film-forming equipment, and the film-forming method includes:

[0081] The substrate 5 is supported outside the working surface of the support plate 1 of the substrate support assembly, and the mask plate 6 (such as a fine metal mask plate) with a hollow pattern (not shown in the figure) is set on the mask plate support assembly 69 , making it contact with the side of the substrate 5 away from the working surface;

[0082] According to the ups and downs of the mask 6, adjust the position of each movable block 2, so that each position of the base 5 is in contact with the mask 6;

[0083] The film forming component 7 is used to form a film on the position of the substrate 5 corresponding to the hollow pattern.

[0084] When using the above film forming equipment to form a film, the position of each movable block 2 can be adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com