Roller compacted concrete dam internal prefabricated corridor structure with buckle connection and implementation method

A technology of roller compacted concrete and corridors, which is applied in water conservancy projects, marine engineering, coastline protection, etc. It can solve the problems of dam body leakage and affect the overall appearance of the inner surface of the corridor, so as to reduce the probability of leakage and improve the overall appearance sex, the effect of ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as any limitation to the present invention.

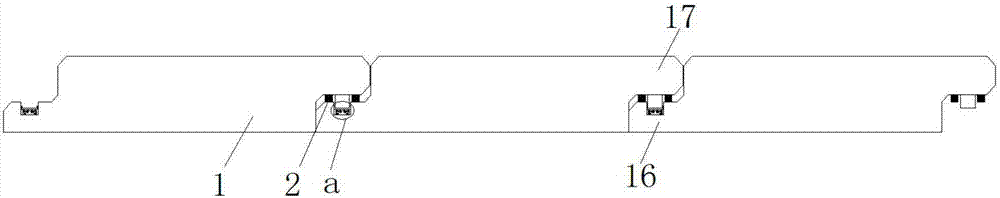

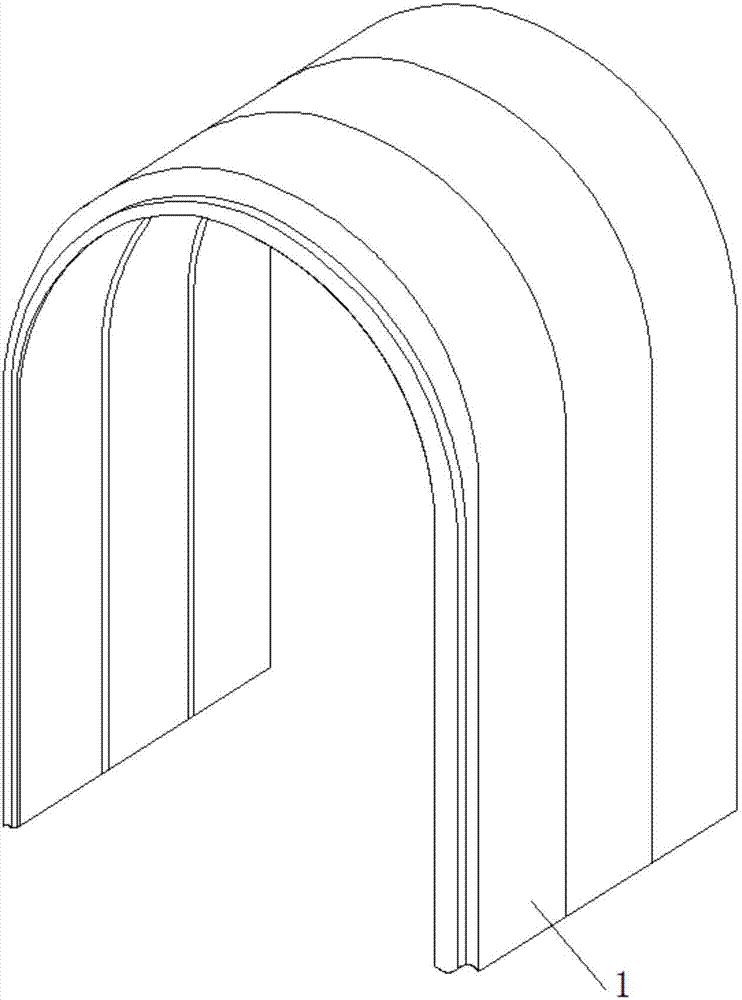

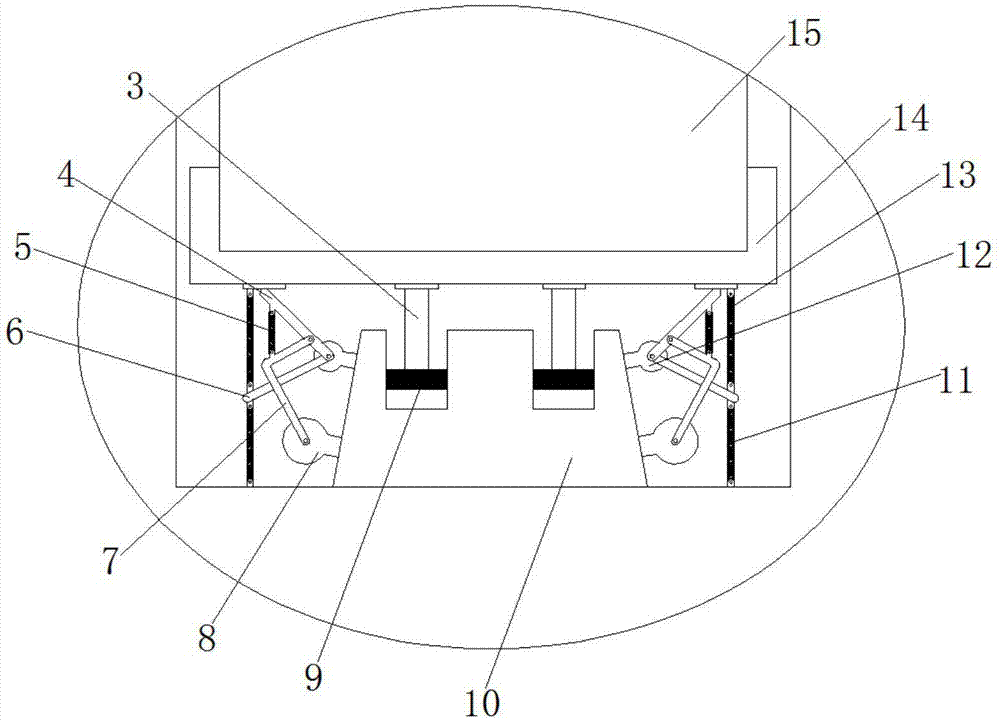

[0020] refer to Figure 1-3 , a prefabricated corridor structure in a roller compacted concrete dam using buckle connections, including a prefabricated corridor 1, the length of the prefabricated corridor 1 is about 0.5m to 1m, which can be adjusted according to the load-carrying conditions of the hoisting equipment, and the prefabricated corridor One side of the part 1 is provided with a positive buckle 16, and the side of the corridor prefabricated part 1 away from the positive buckle 16 is provided with a reverse buckle 17. The size of the positive buckle 16 and the reverse buckle 17 is generally 15 cm in length, and the reverse buckle 17 is fixedly connected with a connection block 15, and the positive buckle 16 is provided with a first groove, and a limit block 10 is arranged in the first groove, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com