Patents

Literature

34results about How to "Eliminate precision errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

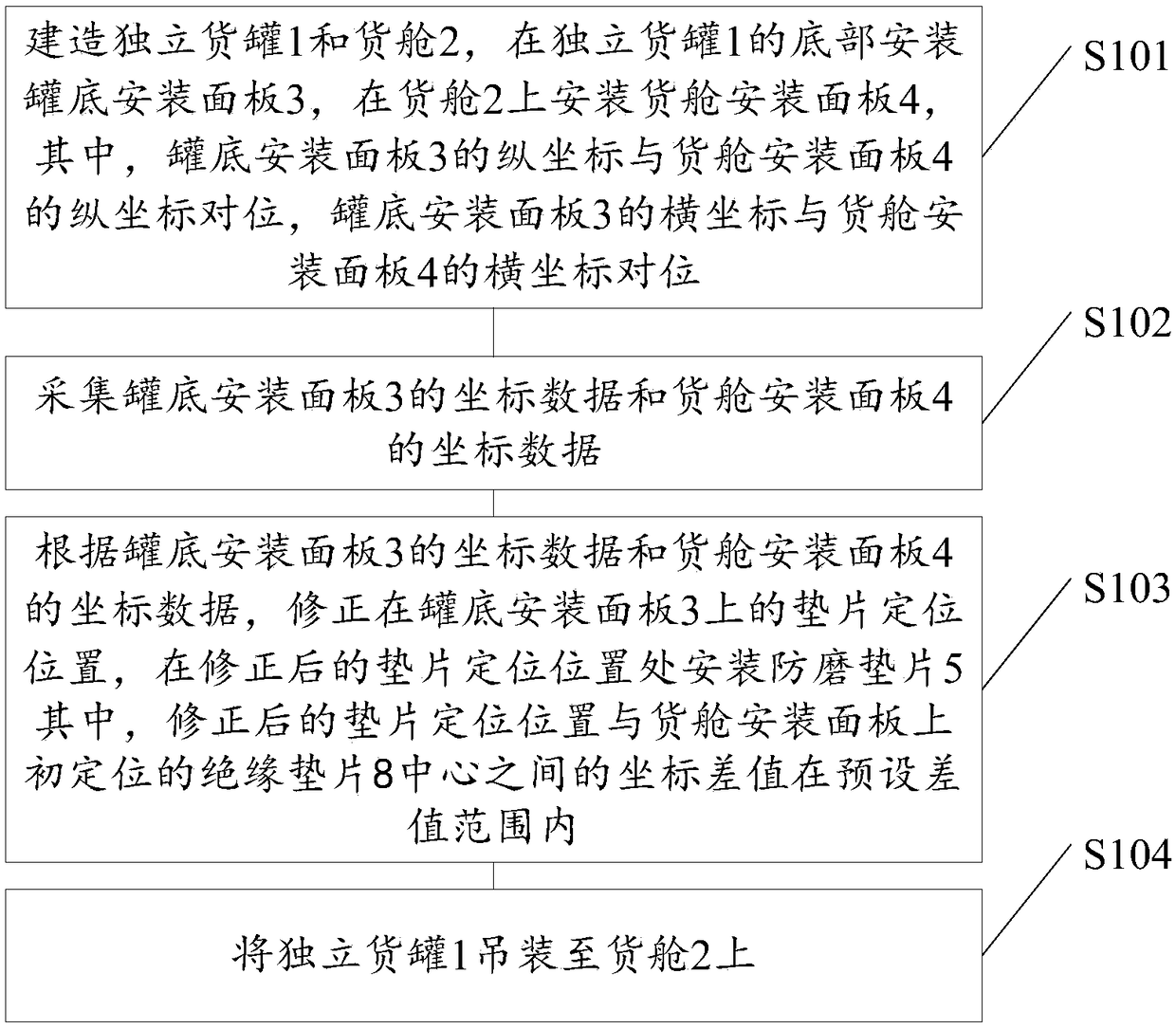

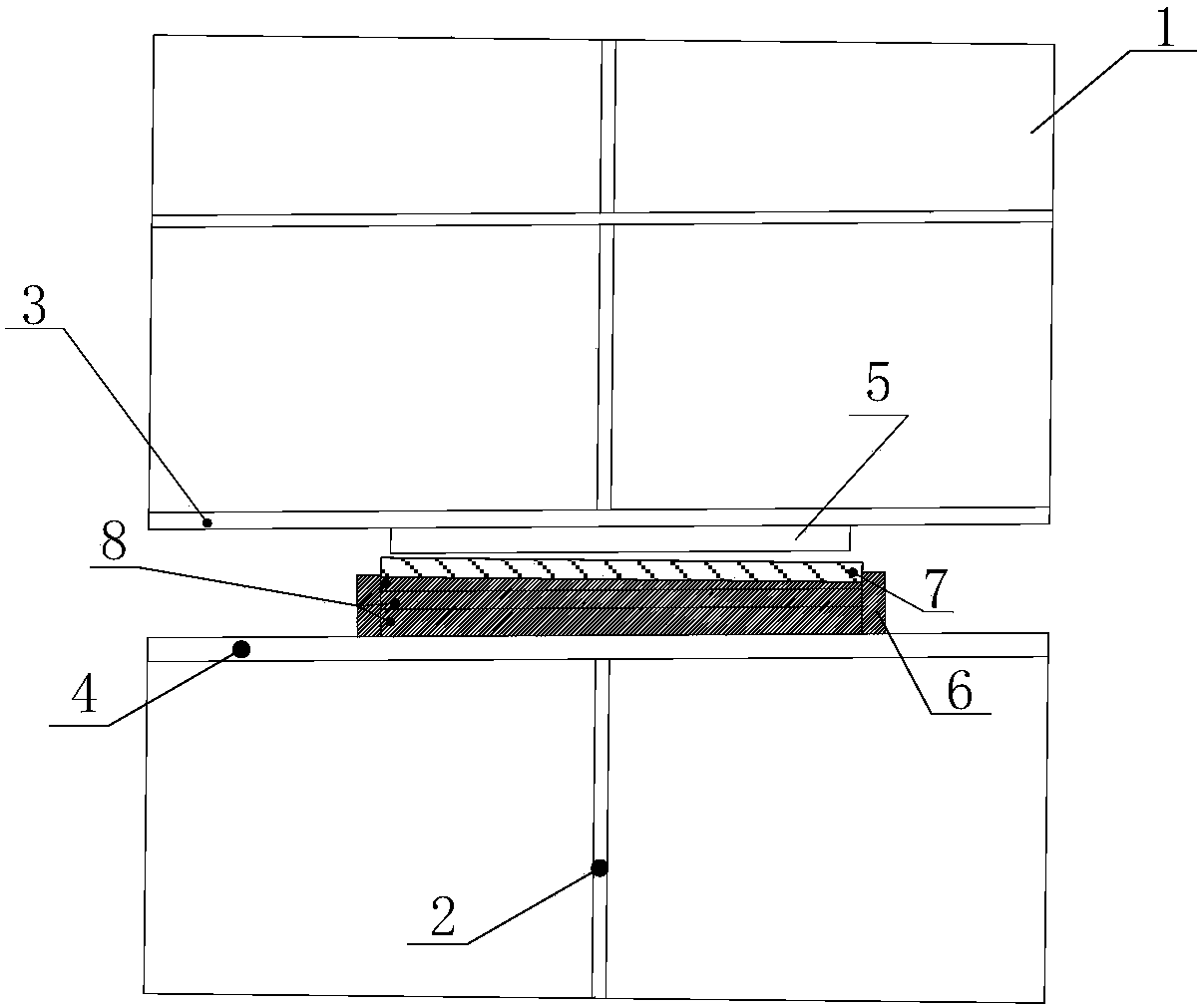

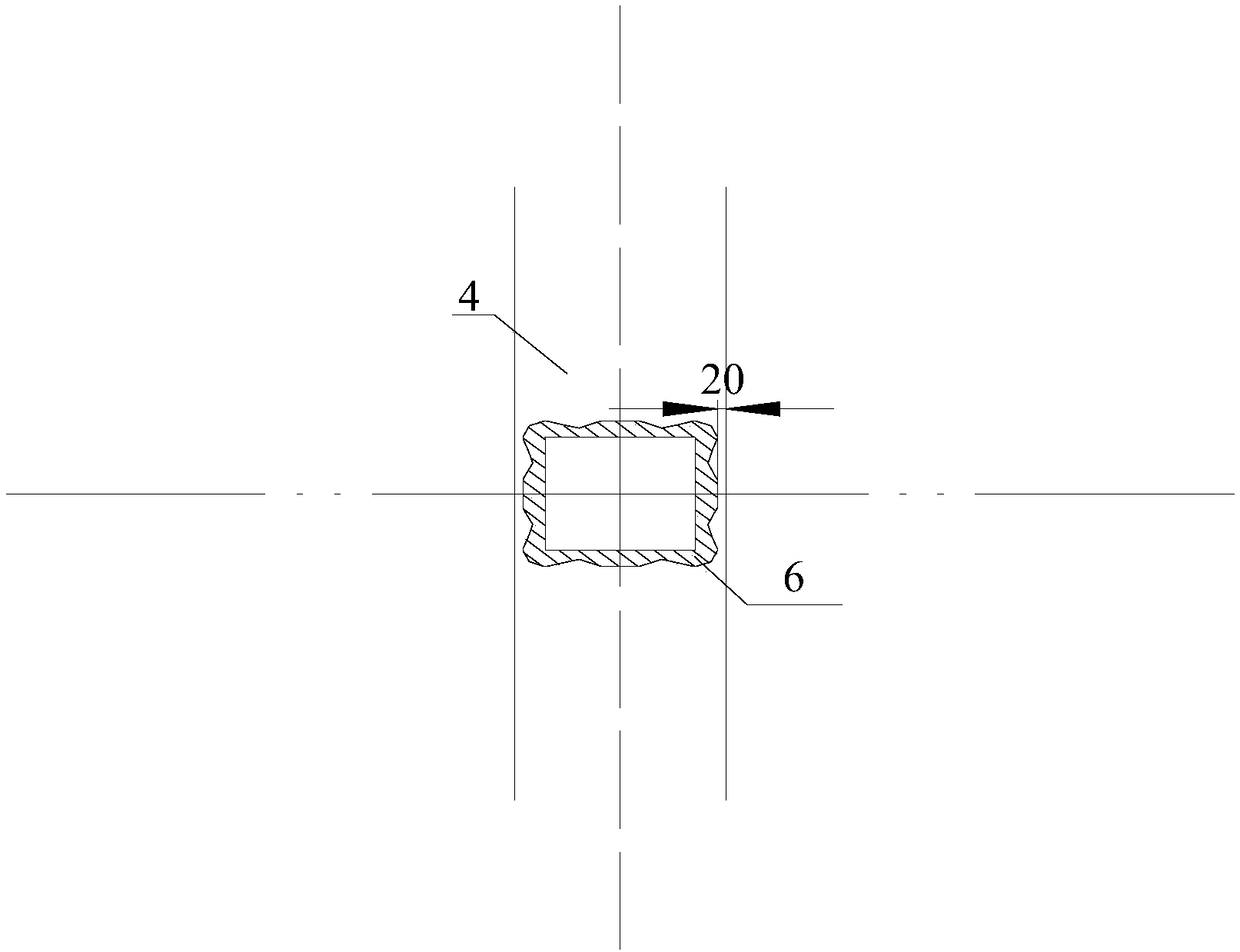

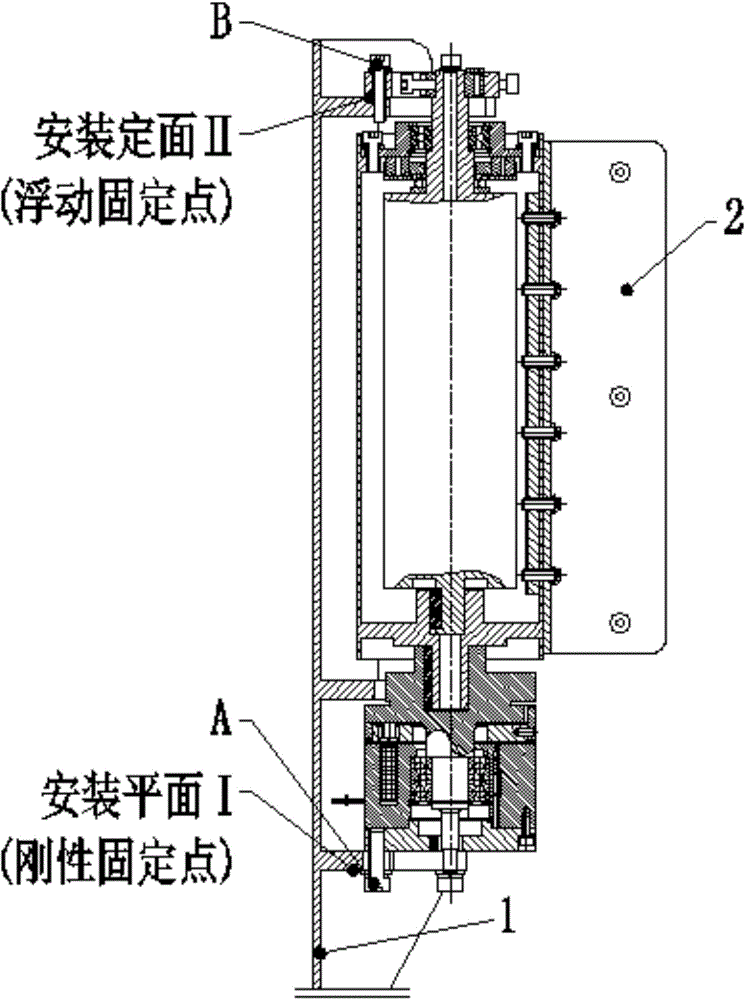

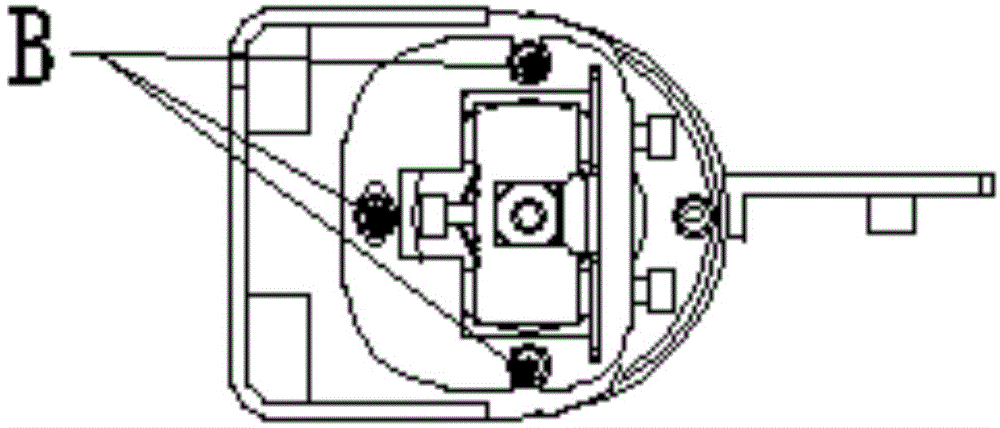

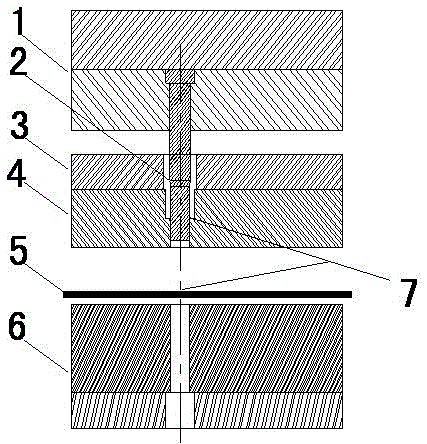

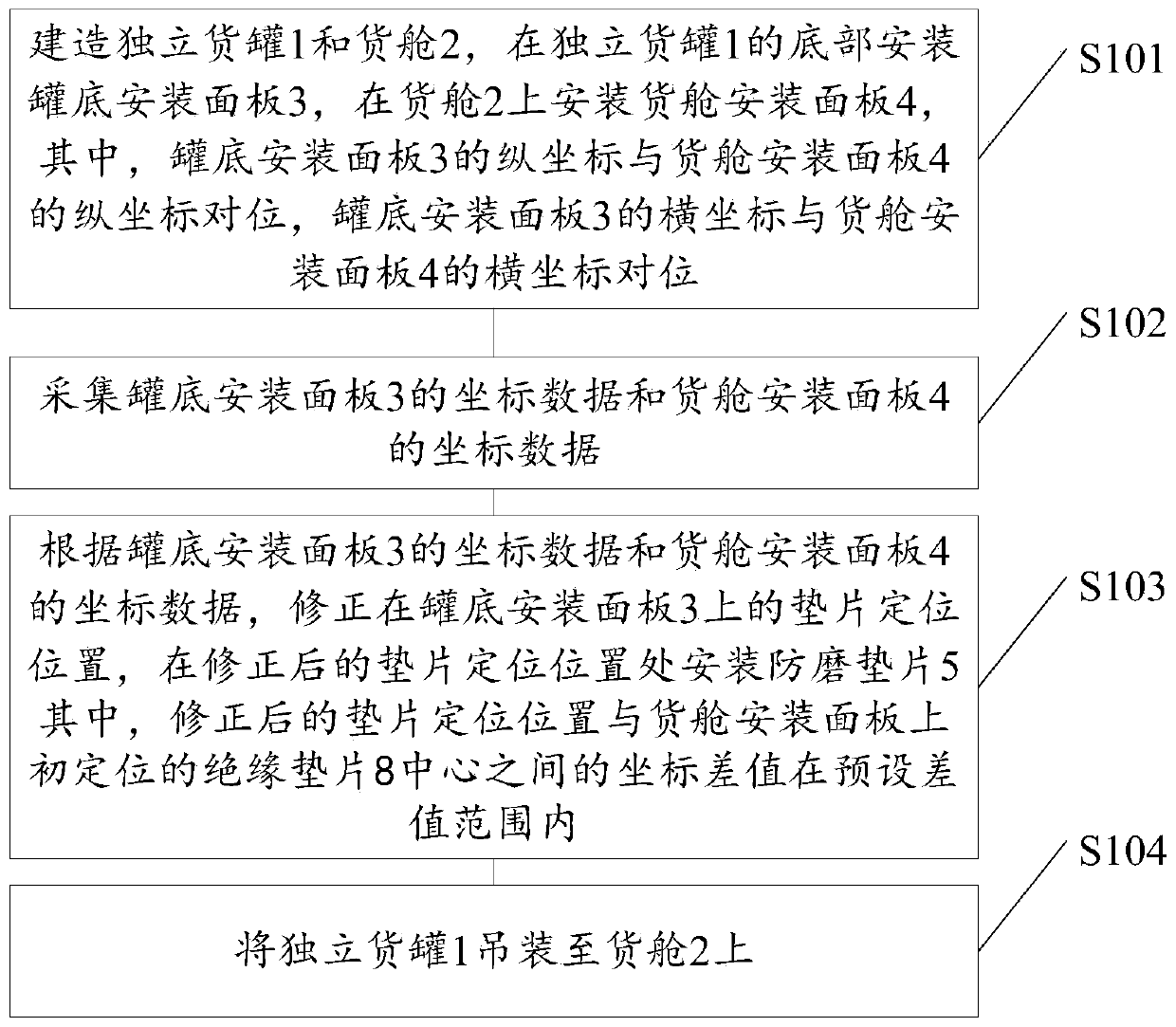

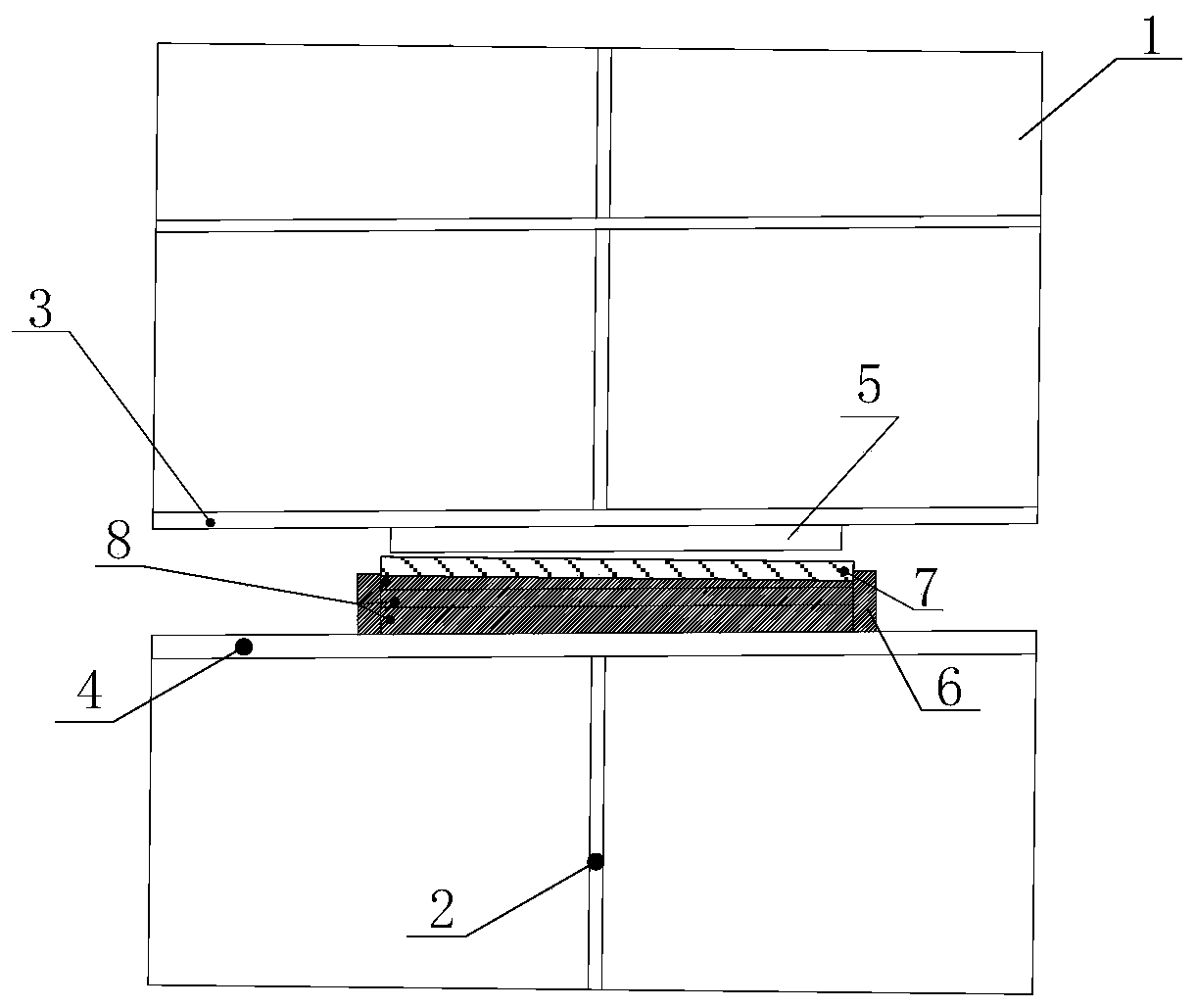

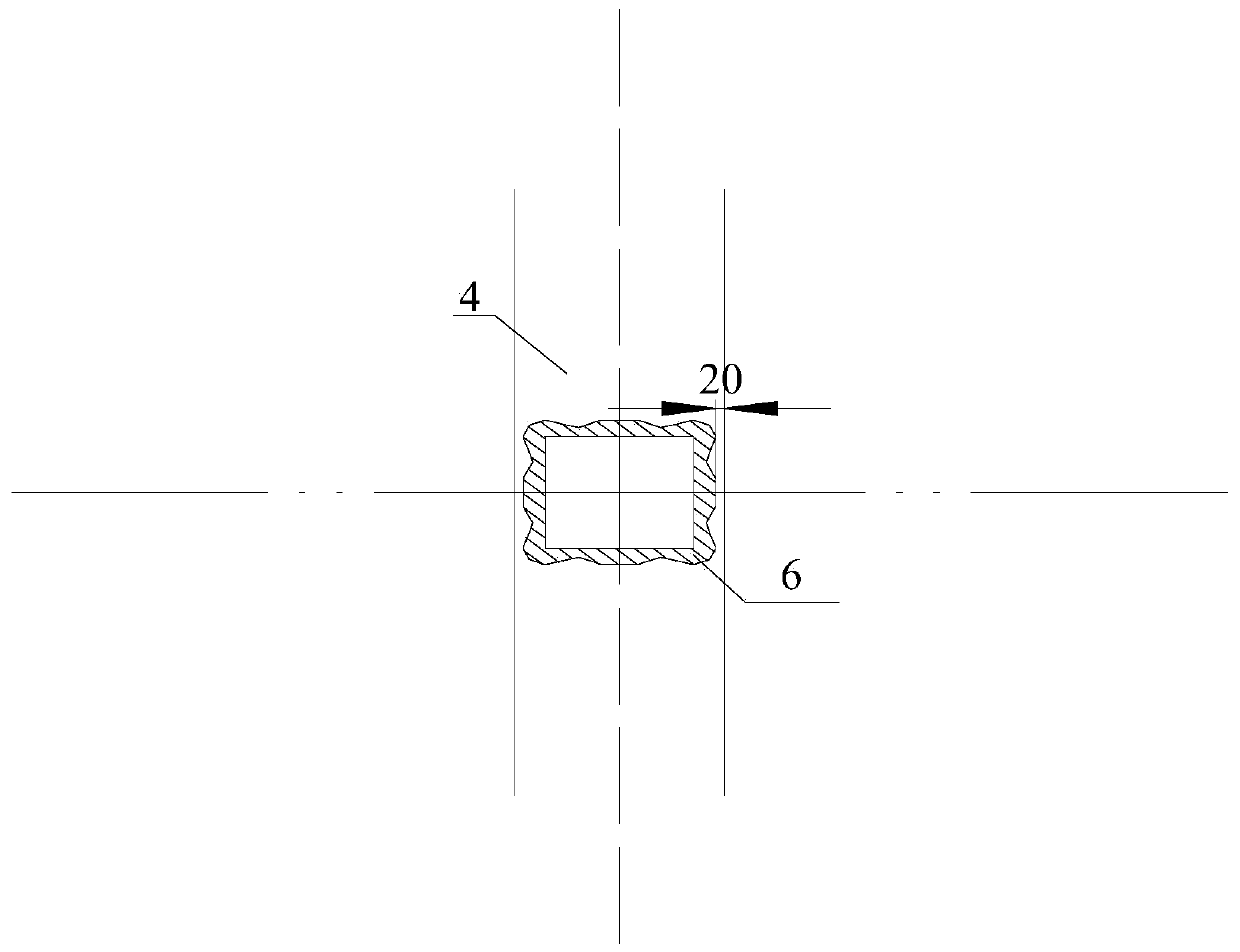

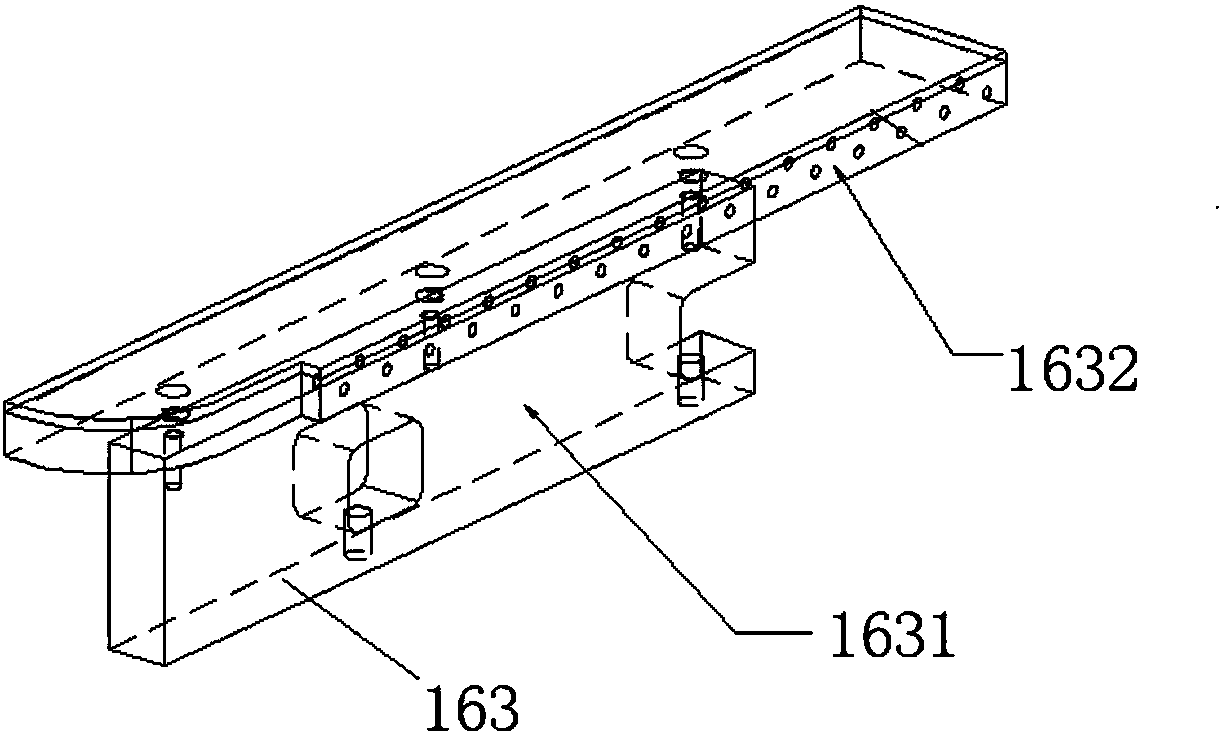

Cargo ship independent cargo tank mounting method

The invention discloses a cargo ship independent cargo tank mounting method. The cargo ship independent cargo tank mounting method comprises the steps that an independent cargo tank and a cargo hold are built, a tank bottom mounting face plate is mounted at the bottom of the independent cargo tank, a cargo hold mounting face plate is mounted on the cargo hold, longitudinal coordinates of the tankbottom mounting face plate are aligned with longitudinal coordinates of the cargo hold mounting face plate, and transverse coordinates of the tank bottom mounting face plate are aligned with transverse coordinates of the cargo hold mounting face plate; coordinate data of the tank bottom mounting face plate and the cargo hold mounting face plate are collected, spacer positioning positions on the tank bottom mounting face plate are corrected according to the coordinate data of the tank bottom mounting face plate and the cargo hold mounting face plate, and abrasion-resistant spacers are mounted in the corrected spacer positioning positions; and the independent cargo tank is hoisted on the cargo hold. Achieving difficulty of each step of precision is lowered, and the effective contact effect between the abrasion-resistant spacers and steel spacers on the upper portions of insulation spacers is improved; and the manual machining workload is reduced, the construction environment is improved,and the building period is shortened.

Owner:HUBEI OCEAN ENG EQUIP RES INST CO LTD

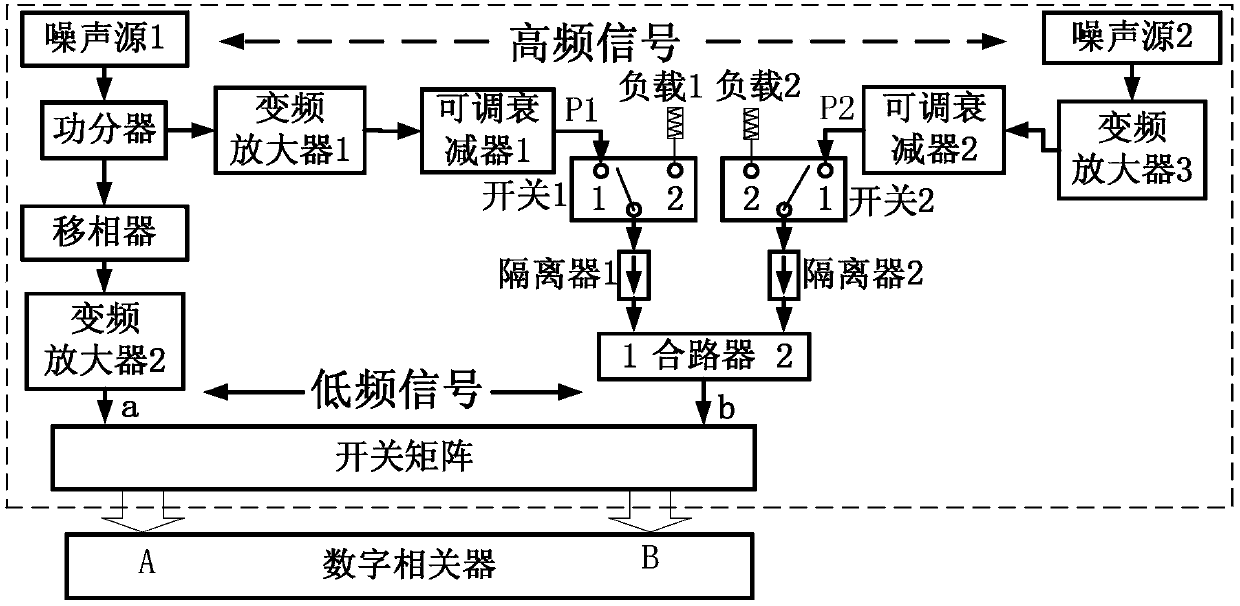

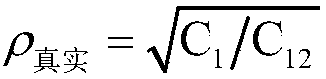

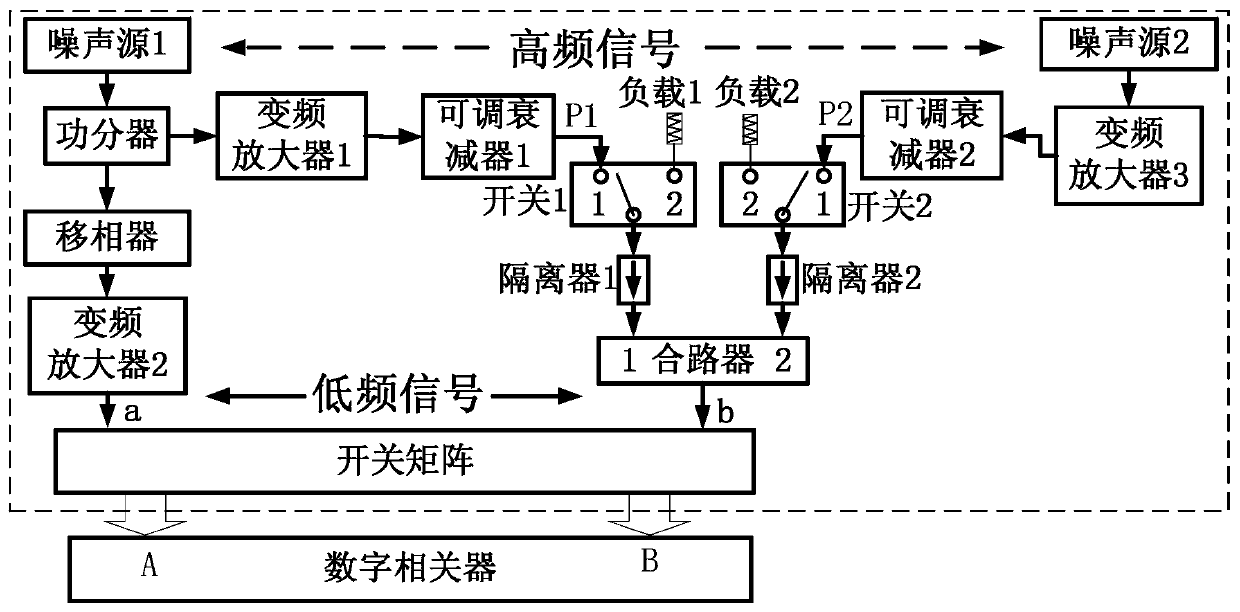

Digital correlator testing system and method

ActiveCN107782993AAvoid situations such as self-excitementImprove stabilityElectrical testingIntermediate frequencyFrequency ratio

The invention relates to a digital correlator testing system and method, and belongs to the space microwave remote sensing technical field; the system and method firstly shunt, amplify, filter and phase shift a high frequency signal source, then carry out signal down conversion to needed intermediate frequency, and finally amplify and output in a combined path; the output signal frequency and thesignal source frequency are different, and segmented amplification is employed, thus effectively preventing inter-channel crosstalk and amplifier self excitation conditions, and greatly improving theoutput signal stability. The noise signal phase shift operations of the method are carried out in the high frequency band, thus reducing the signal bandwidth frequency ratio (B / f<<0.05), effectively eliminating the correlation noise signal decorrelation effect, and greatly improving the output signal correlation precision; the method is suitable for all digital correlator tests.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

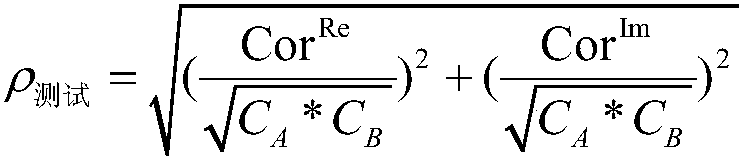

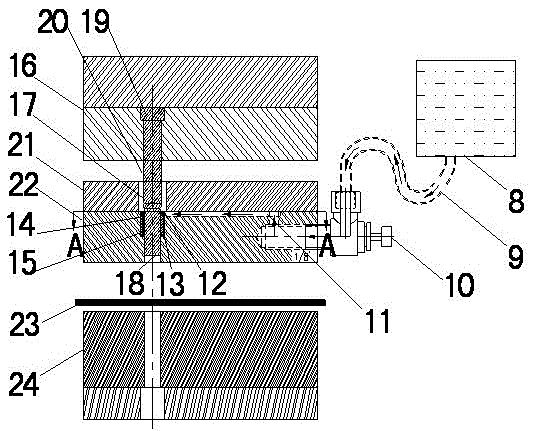

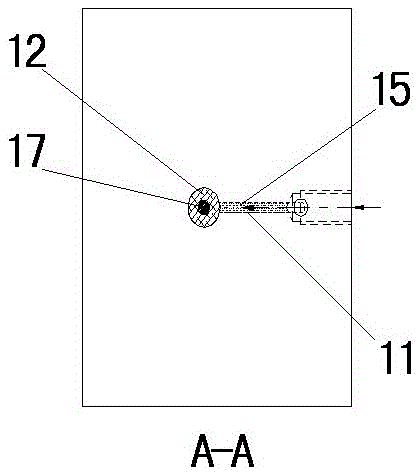

Floating and breakage preventing screw tap clamp

The invention discloses a floating and breakage preventing screw tap clamp. The floating and breakage preventing screw tap clamp is characterized by comprising a screw tap chuck, an upper slotted set screw, a lower slotted set screw, a guide sleeve, a rotation stopping bolt, a sliding ferrule, a mandrel, an outer hexagon nut, a torque transmission steel ball, a torque transmission spring and a clamp handle. During use, by using the floating and breakage preventing screw tap clamp, automatic feed in the tapping process is realized; meanwhile, disalignment error, mounting errors of workpieces, precision error of a machine tool and the like after a machine tool spindle and a drum turret are repeatedly positioned are eliminated, and the processing precision of threads is improved; meanwhile, the common problem that a screw tap is twisted off during automatic tapping due to chip blockage, disalignment, low roughness, over tapping and the like is solved; new workers can ensure the processing quality of products, so that the qualified rate of the products is greatly improved, and the processing cost is effectively reduced; and in addition, the floating and breakage preventing screw tap clamp has the advantages of simple structure, flexibility, reliability and low cost.

Owner:HENGYANG TEXTILE MACHINERY MANUFACTORY +1

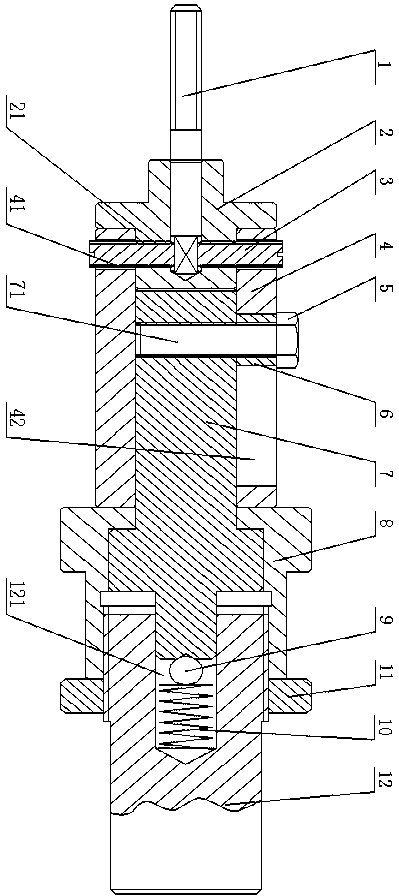

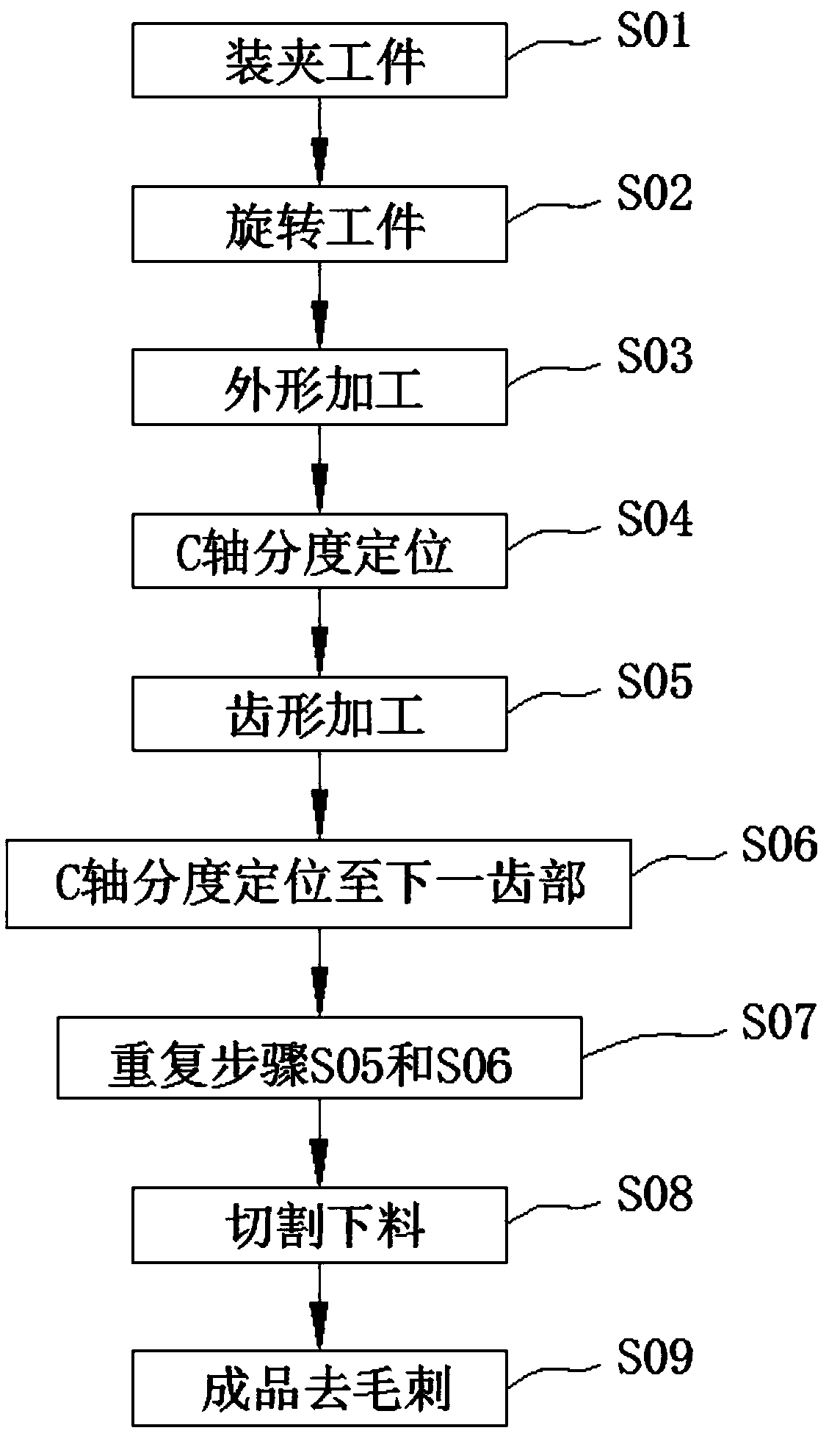

Spur gear numerical control machining method

InactiveCN108994553AGuaranteed machining accuracyEliminate precision errorsNumerical controlEngineering

The invention provides a spur gear numerical control machining method. The spur gear numerical control machining method comprises the following steps that step S01, a workpiece is clamped; step S02, the workpiece is rotated; step S03, shape machining is performed; step S04, C-axis indexing positioning is performed; step S05, tooth profile machining is performed; step S06, C-axis indexing positioning is performed to a next tooth part; step S07, the step S05 and the step S06 are repeated; step S08, cutting and blanking are performed; and step S09, burrs and sharp edges of finished products are removed. The workpiece product manufactured by the spur gear numerical control machining method can eliminate the precision error problem caused by the secondary positioning clamping during the spur gear tooth profile machining, the workpiece product is machined on a CNC machine tool from the machining to the finished product blanking, midway discharging is not needed for secondary clamping machining, and the machining accuracy of the gear is ensured.

Owner:宁波联合蓝光科技有限公司

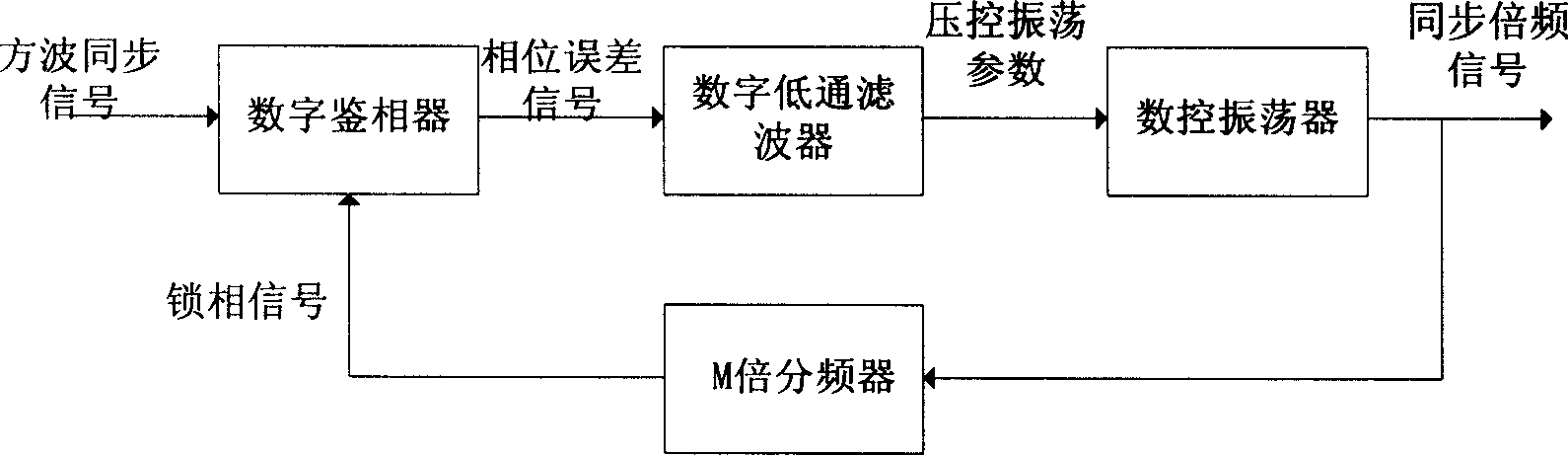

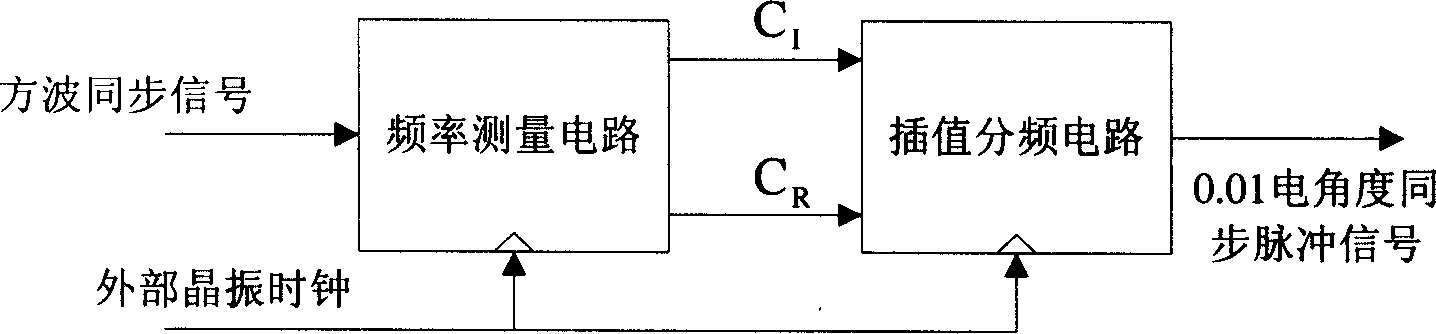

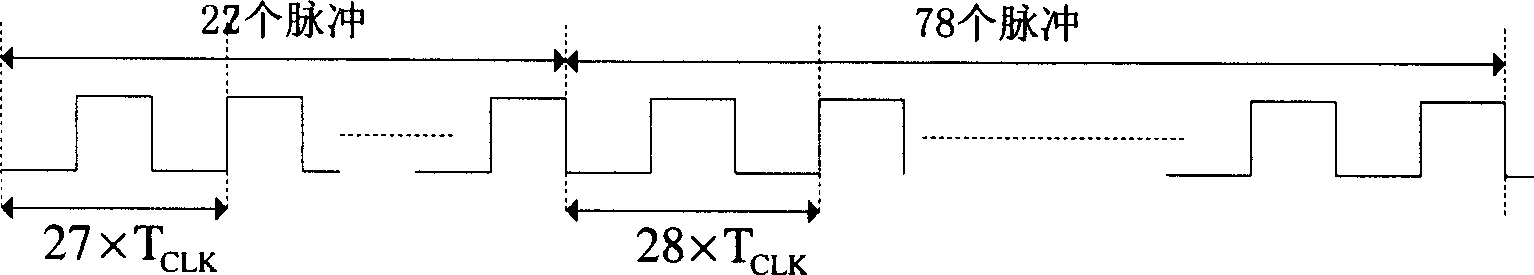

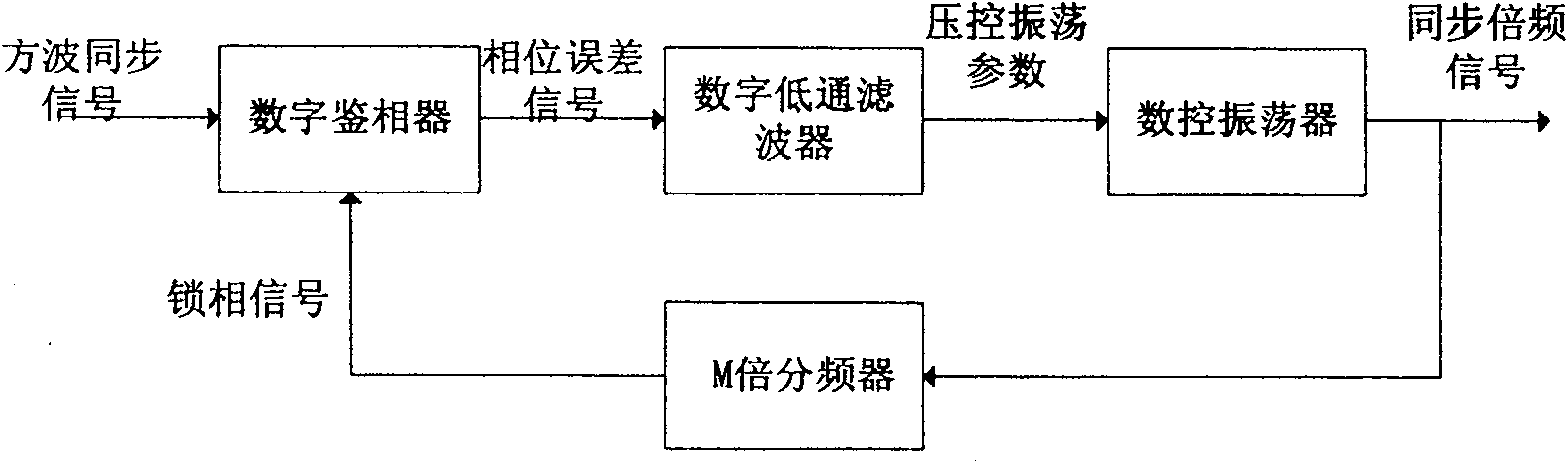

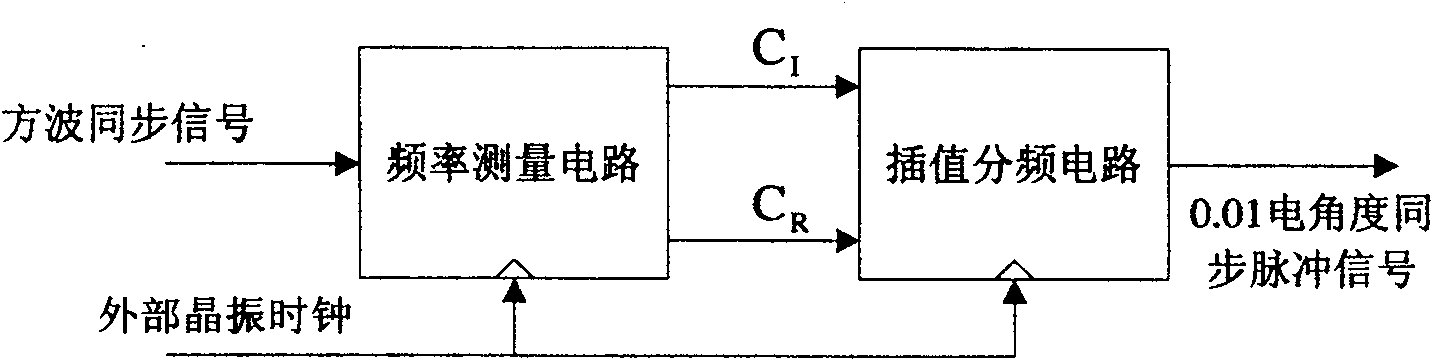

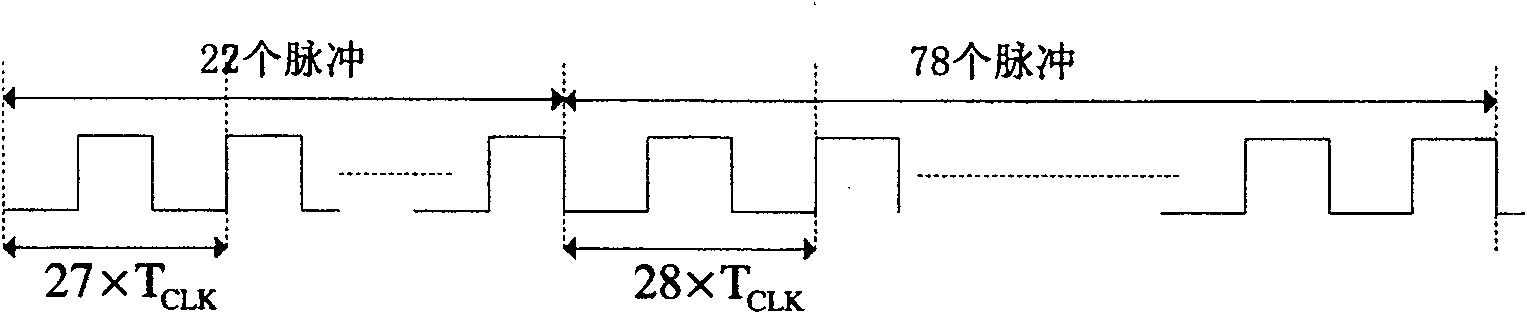

Digital tracking method of synchronous phase angle

InactiveCN1702971AEasy to handleEliminate precision errorsPulse automatic controlFrequency measurementsElectrical and Electronics engineering

This invention relates to simultaneous phase angle digital tracing method in the relative technique field and is characterized by the following: first inputting the simultaneous signals into radio measurement circuit to get the frequency division of outer crystal clock of CI and plug parameters of CR; then using the CI, CR as frequency division values input to the plug and division circuit.

Owner:TSINGHUA UNIV

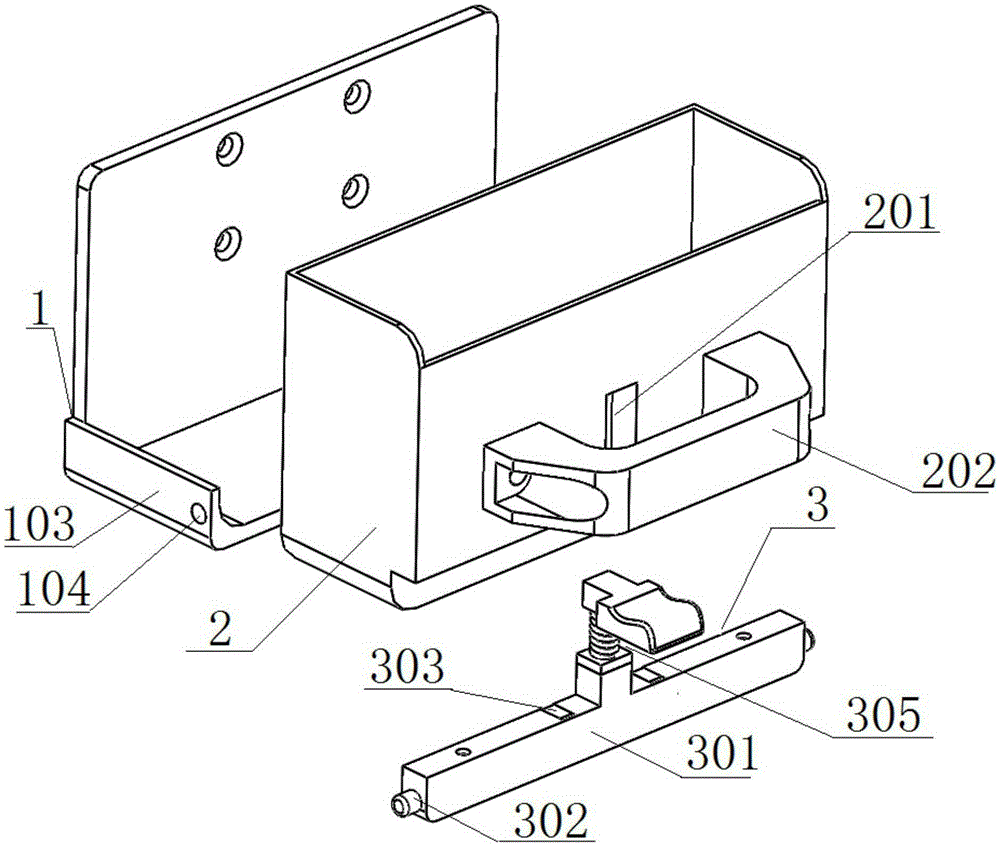

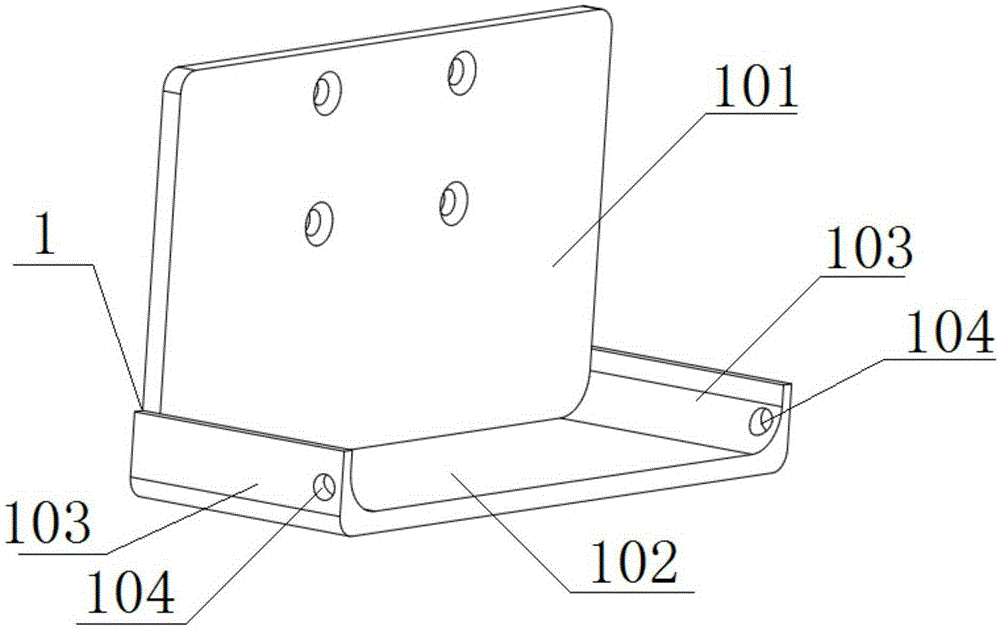

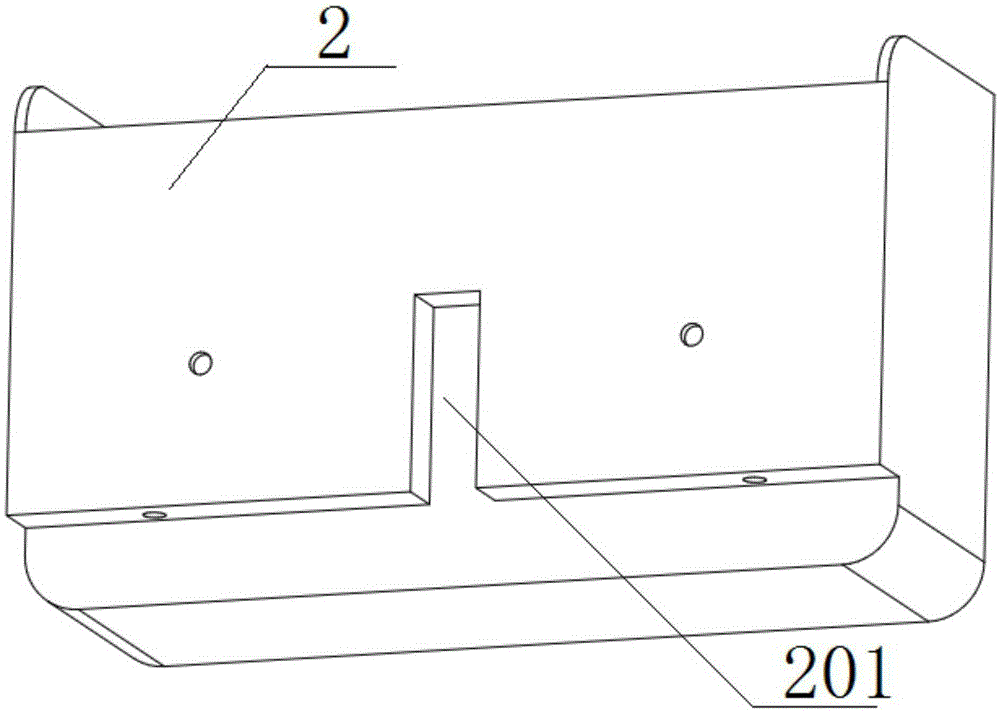

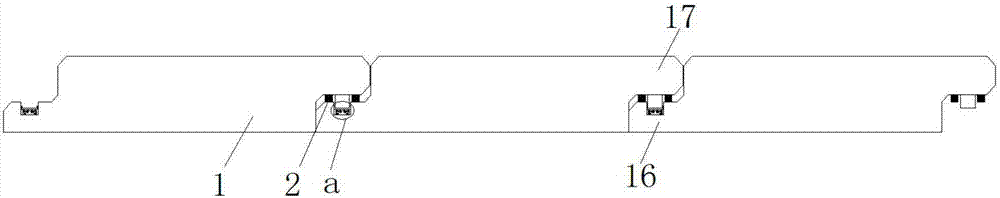

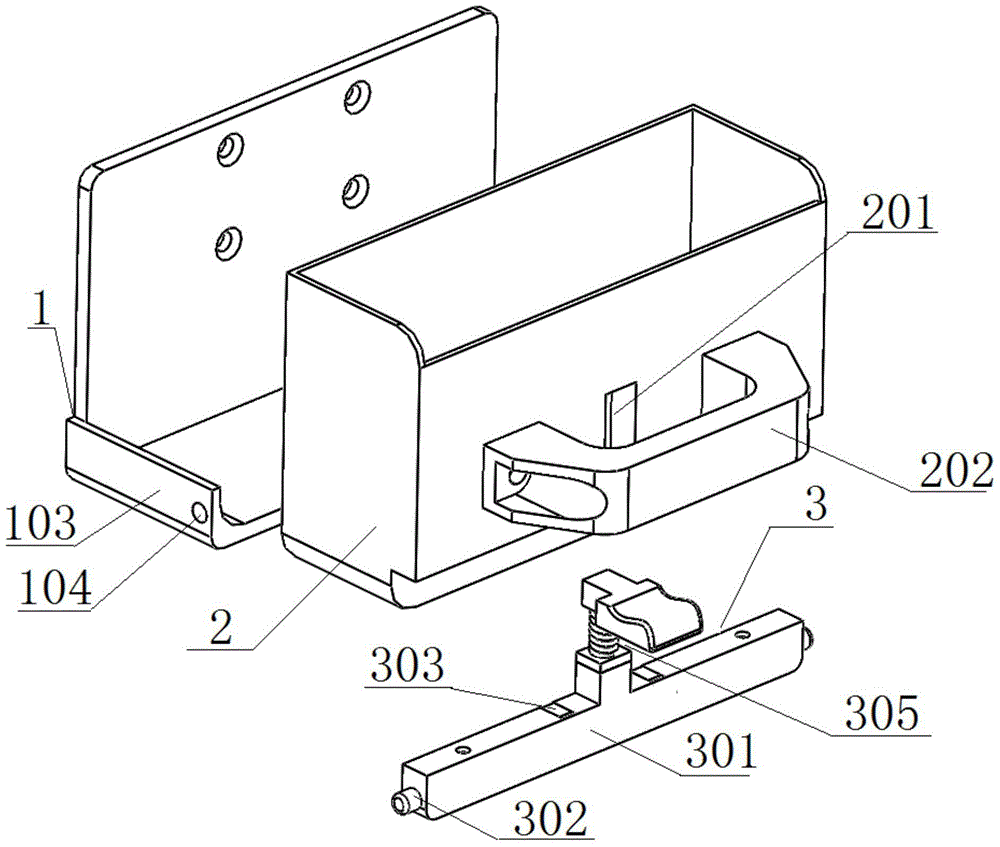

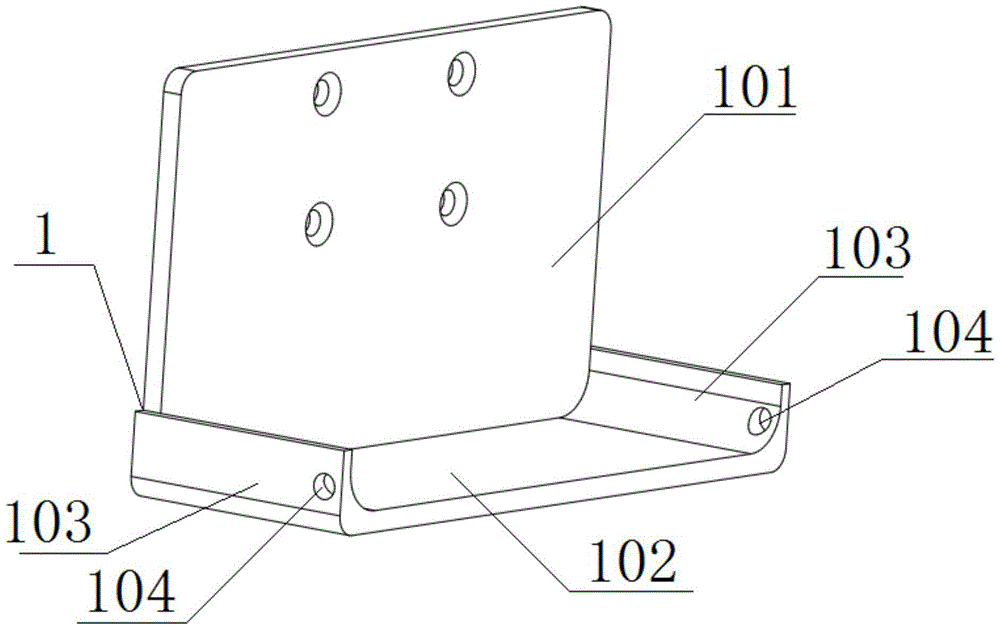

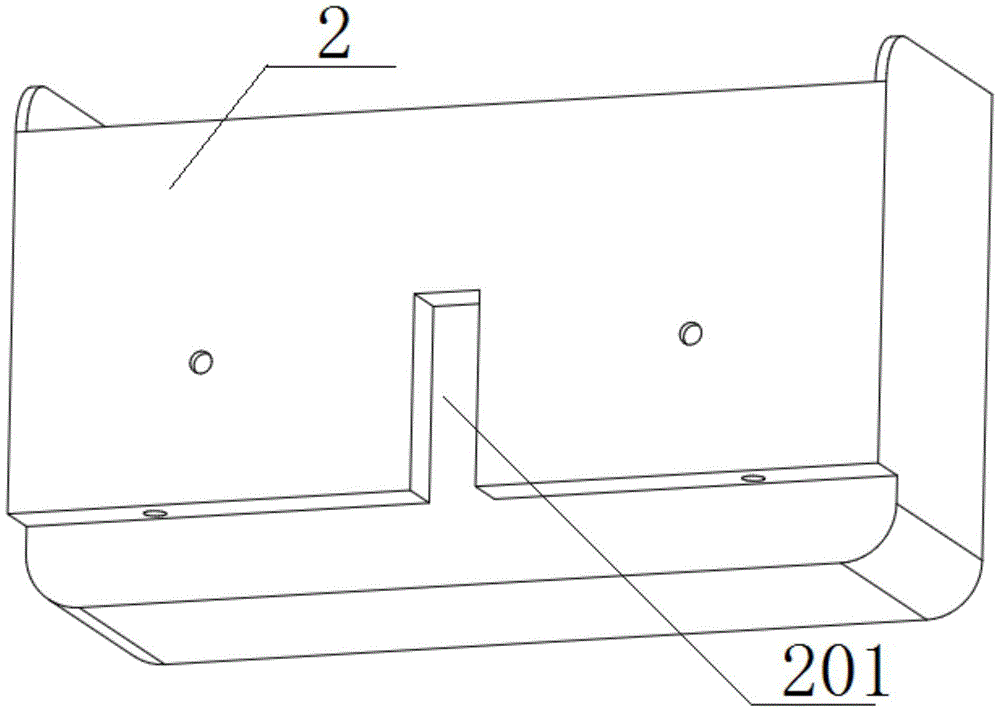

Automatic positioning cuttings accumulating box of slicing machine

ActiveCN105313171ANo loosenessRealize automatic positioningWithdrawing sample devicesMetal working apparatusAxial displacementEngineering

The invention relates to an automatic positioning cuttings accumulating box of a slicing machine. The box comprises a support, a box body and a positioning device. The positioning device comprises a clamping rod supporting box, clamping rods, a positioning block, limiting springs and a limiting element. Limiting holes corresponding to positioning holes are formed in the left side face and the right side face of the clamping rod supporting box, and the left side face is opposite to the right side face. The number of the clamping rods is two. The limiting element comprises a limiting rod and a return spring. One end of the limiting rod is provided with a wedge block, the other end of the limiting rod is provided with a cap-shaped pressing head, and the middle of the limiting rod is provided with a limiting block capable of sliding on the limiting rod. The portion, between the cap-shaped pressing head and the limiting block, of the limiting rod located is sleeved with the return spring. By means of the automatic positioning cuttings accumulating box, automatic positioning can be achieved. The limiting springs on the clamping rods can automatically compensate for axial displacement to guarantee that clamping is not loosened. The positioning structure is simple, and cutting precision and stability are guaranteed. The pressing head is pushed downwards through lower cap-shaped pressure of fingers to drive the clamping rods to retract, the box body is disengaged from the support, quickness and reliability are achieved, and the cuttings accumulating box is convenient to disassemble and assemble.

Owner:WUHAN OE BIO CO LTD

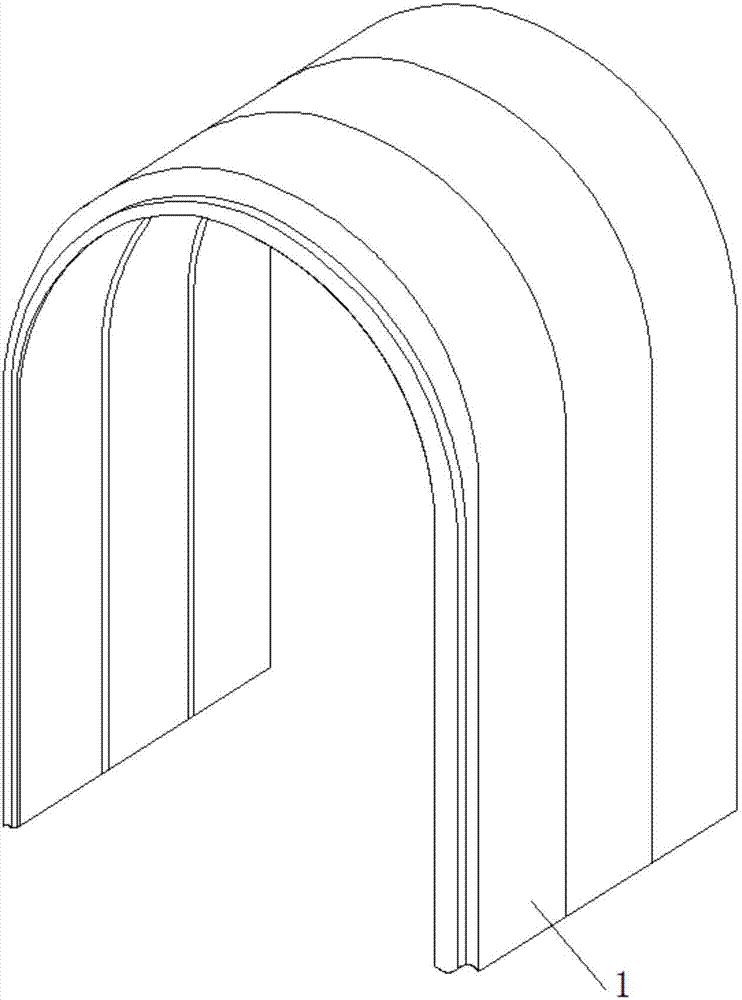

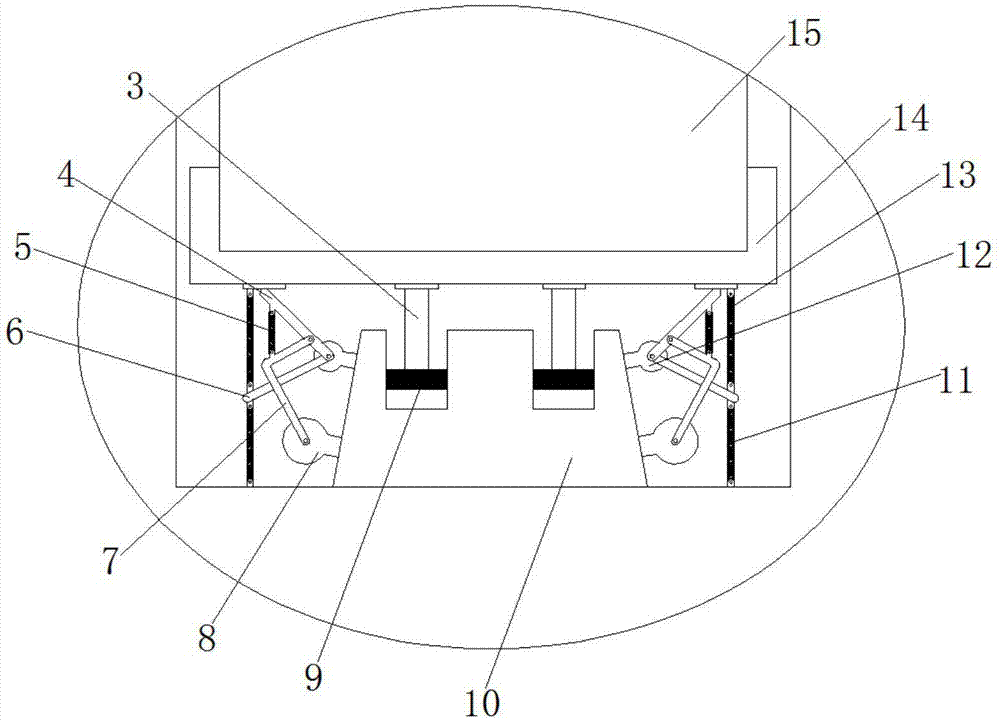

Roller compacted concrete dam internal prefabricated corridor structure with buckle connection and implementation method

ActiveCN107366258AImprove aestheticsIngenious structureBarrages/weirsHydro energy generationRoller-compacted concreteEngineering

The invention discloses a roller compacted concrete dam internal prefabricated corridor structure with buckle connection and an implementation method. The roller compacted concrete dam internal prefabricated corridor structure comprises a corridor prefabricated part, one side of the corridor prefabricated part is provided with a positive buckle, one side, away from the positive buckle, of the corridor prefabricated part is provided with a negative buckle, a connection block is fixedly connected with the negative buckle, the positive buckle is provided with a first groove, the first groove is provided with a limit block, two first fixed disks and two second fixed disks are symmetrically arranged on the limit block, and a first connecting rod and a second connecting rod are rotatably connected with the first fixed disk. The roller compacted concrete dam internal prefabricated corridor structure has the advantages that the structure is ingenious, the use is convenient, the accuracy error of artificial hoisting can be eliminated, and the irregular faulting of slab ends caused by the vibrational rolling excited vibration force during the construction process of roller compact concrete can be completely avoided, the overall beauty of the inner surface of the prefabricated corridor is greatly improved, the probability of leakage in the joint part of the prefabricated part of the corridor is greatly reduced after the reservoir is impounded, and is worthy of being popularized.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

Automatic positioning chip accumulation box of a slicer

ActiveCN105313171BNo loosenessRealize automatic positioningWithdrawing sample devicesMetal working apparatusAxial displacementBiomedical engineering

Owner:WUHAN OE BIO CO LTD

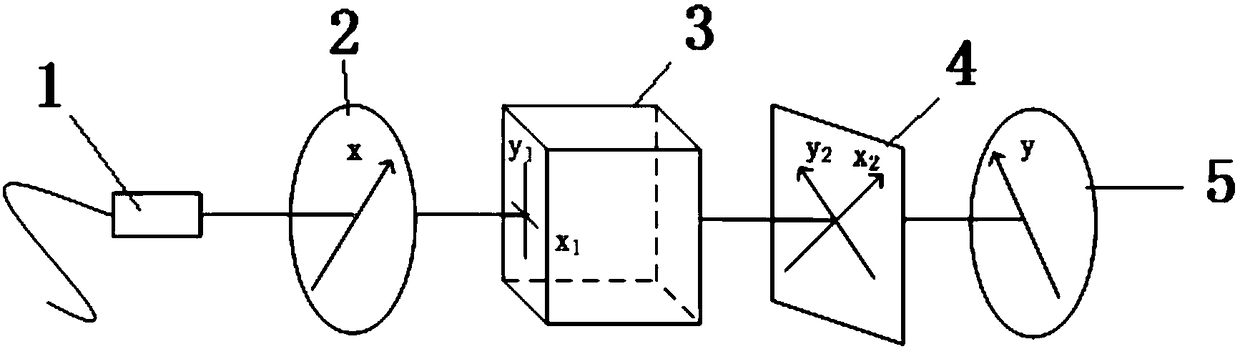

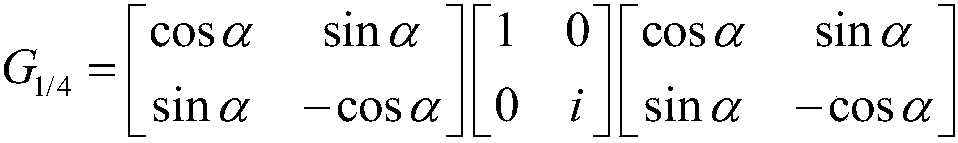

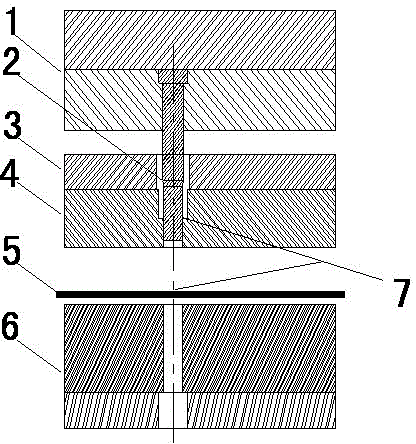

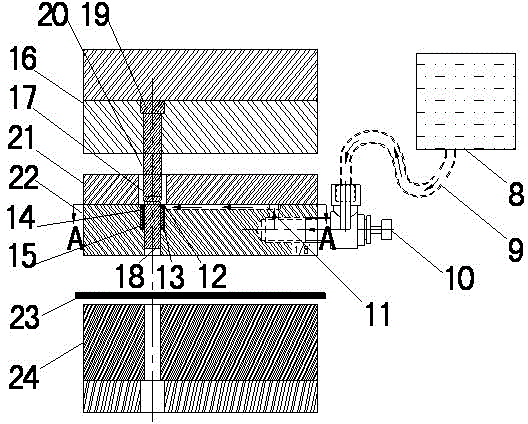

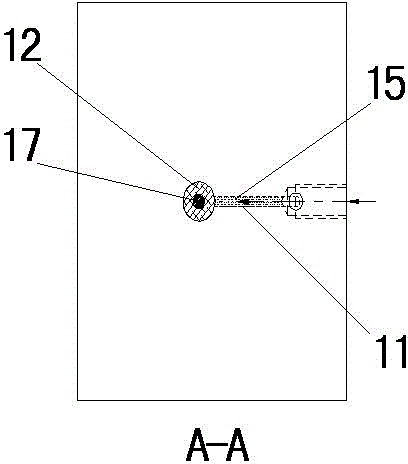

Atomic gas chamber surface stress test device and test method

PendingCN108106759AHigh precisionEasy to install and debugForce measurement by measuring optical property variationStress distributionSurface stress

The invention belongs to the technical field of gas chamber surface stress test, and specifically discloses an atomic gas chamber surface stress test device and test method. The device comprises a laser collimator, a polarizer, an atomic gas chamber, a 1 / 4 wave plate, a polarization analyzer and a CCD and lens. The device further comprises a fixed mounting base, an optical adjustment frame and four support rods. The method comprises the following steps: after a light source passes through the laser collimator and the polarizer, two beams of linearly polarized light are formed; a phase difference of PI / 2 is produced between the two beams of light; the zero position of the polarization analyzer is recorded; a gas chamber stress distribution picture with gray values is recorded by the CCD; and the correspondence between the gray values of the positions of the gas chamber and the rotation angle of the polarization analyzer is obtained, the angle of the polarization analyzer corresponding to the point with the minimum gray value at each position is obtained through fitting, and finally, the stress value distribution of the gas chamber is obtained. Precision error caused by direct measurement is eliminated, and the precision is improved. The atomic gas chamber surface stress test device adopts a cage structure, which facilitates light path alignment. Moreover, the device has a simpleand compact structure, and is stable and reliable.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

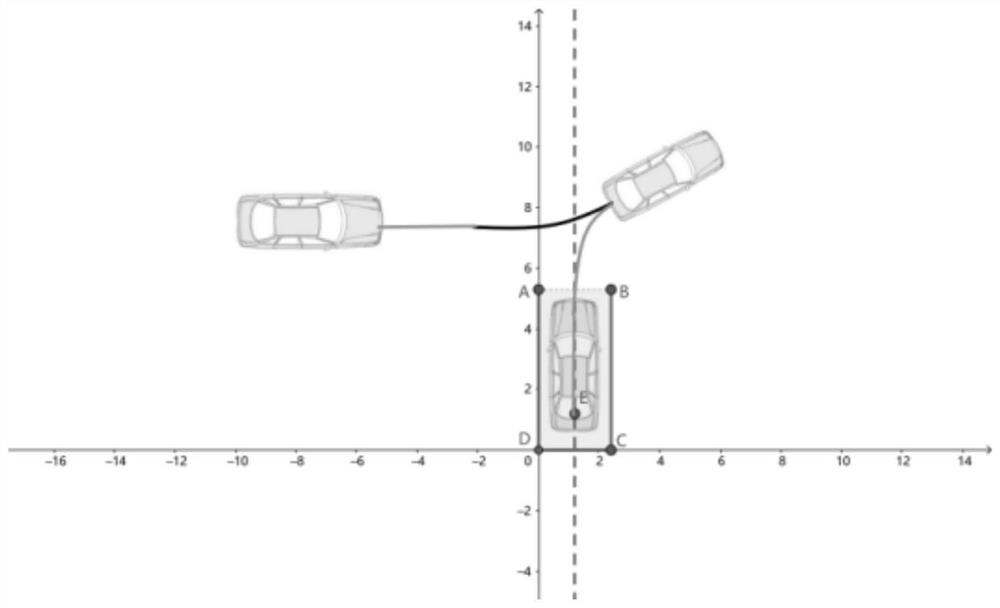

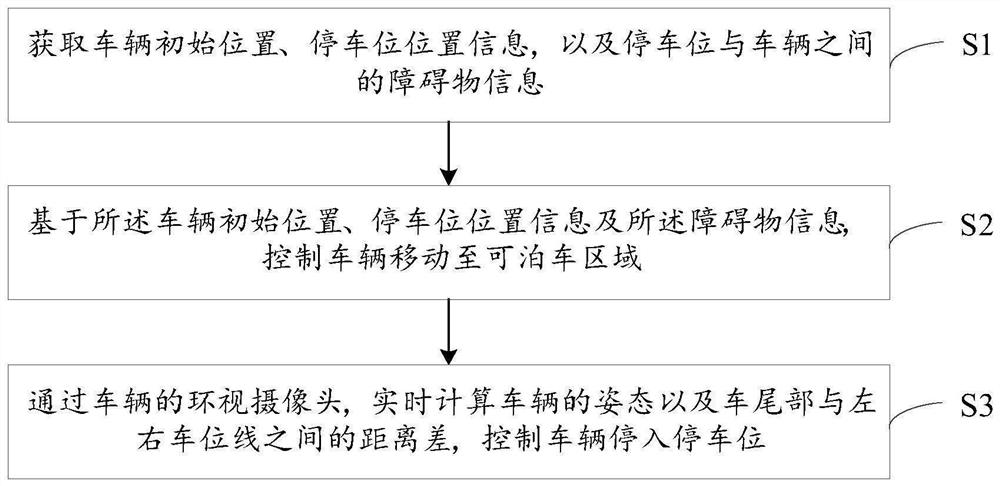

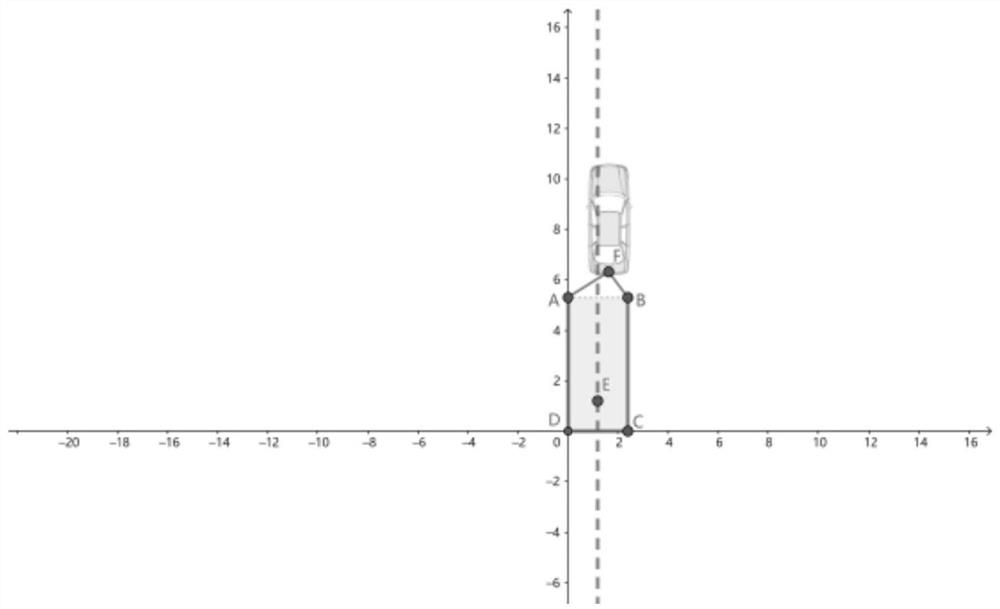

Automatic parking decision planning method and system

The invention provides an automatic parking decision planning method and system. The method comprises the following steps: collecting the initial position of a vehicle, the position information of a parking space and the information of an obstacle between the parking space and the vehicle; and controlling the vehicle to move to a parking area based on the initial position of the vehicle, the parking space position information and the obstacle information. The attitude of the vehicle and the distance difference between the tail part of the vehicle and the left and right parking space lines are calculated in real time through an all-round camera of the vehicle, and the vehicle is controlled to be parked in the parking space. When automatic parking decision planning is carried out, the distance between the vehicle and the left and right parking space lines of the parking space is detected in real time through a camera or an ultrasonic radar installed on the vehicle, the distance data serve as input of decision planning, and track information of the next point of the vehicle is planned in real time, so that the precision error of a traditional APA decision algorithm is eliminated; the precision of automatic parking decision planning is improved.

Owner:WUHAN KOTEI INFORMATICS

Fixed swing gate movement with damping property and flexibility

ActiveCN104831647ADamage reliefEliminate vibration noiseTraffic restrictionsEngineeringTreatment quality

The invention discloses a fixed swing gate movement with damping property and flexibility. A radial buffering body and an axial buffering body are additionally arranged in an inner structure of the movement. In an operation process of the movement, vibration noise caused by manufacturing and mounting errors is not caused; meanwhile, in a rotation process, when the movement is dynamically impacted, the damage of the impact to a movement component can be relieved, and the impact of gate machine passage pedestrians to a vehicle can also reduced. A door wing fixing plate in a rotating cylinder component is connected to a rotating cylinder by a screw or a rivet other than a welding way, so that machining and surface treatment on the rotating cylinder are greatly facilitated, the surface treatment quality can be improved, and precision error caused by a connecting process is eliminated.

Owner:CHENGDU QIANFAN TECH DEV

Automatic lubricating and cooling mechanism for stamping male dies

ActiveCN104475588AMaintain lubricity in real timeKeep cool in real timeShaping toolsCooling downOil pressure

The invention discloses an automatic lubricating and cooling mechanism for stamping male dies. The automatic lubricating and cooling mechanism comprises an oil cup, wherein an oil outlet end of the oil cup is parallel and level to the lower end of a fixing plate and is connected with a first oil tube in parallel; the other end of the first oil tube is connected with one end of an adjusting valve; the other end of the adjusting valve is connected with a second oil tube; the other end of the second oil tube is communicated with an oil storage cavity; a first oil seal and a second oil seal are respectively arranged at two ends of the oil storage cavity; the oil storage cavity is formed in a discharging plate of a die; a punch penetrates in the oil storage cavity; the first oil seal and the second oil seal are arranged between a die head and a die shank of the punch; and the oil pressure between the oil cup and the oil storage cavity keeps balanced by adjusting the adjusting valve. When the punch moves in the up-down direction, a die rod positioned between the die head and the die shank are always soaked in stamping oil in the oil storage cavity partially, and the punch is always lubricated and cooled down by the stamping oil. By the automatic lubricating and cooling mechanism for the stamping male dies, the safety of workers, the efficiency and the quality of the stamping male dies are greatly improved, and the service lives of the stamping male dies are greatly prolonged.

Owner:SEKSUN TECH SUZHOU

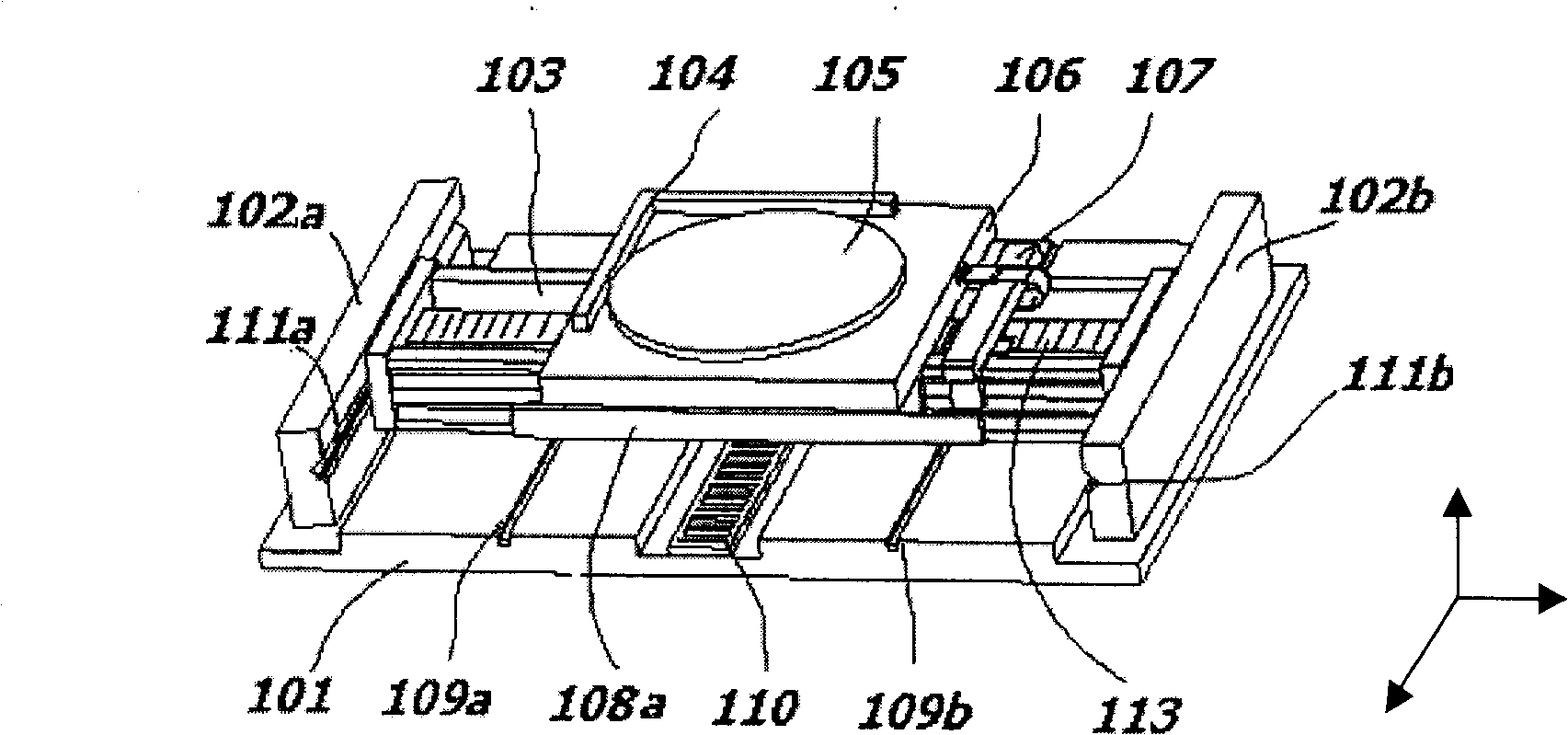

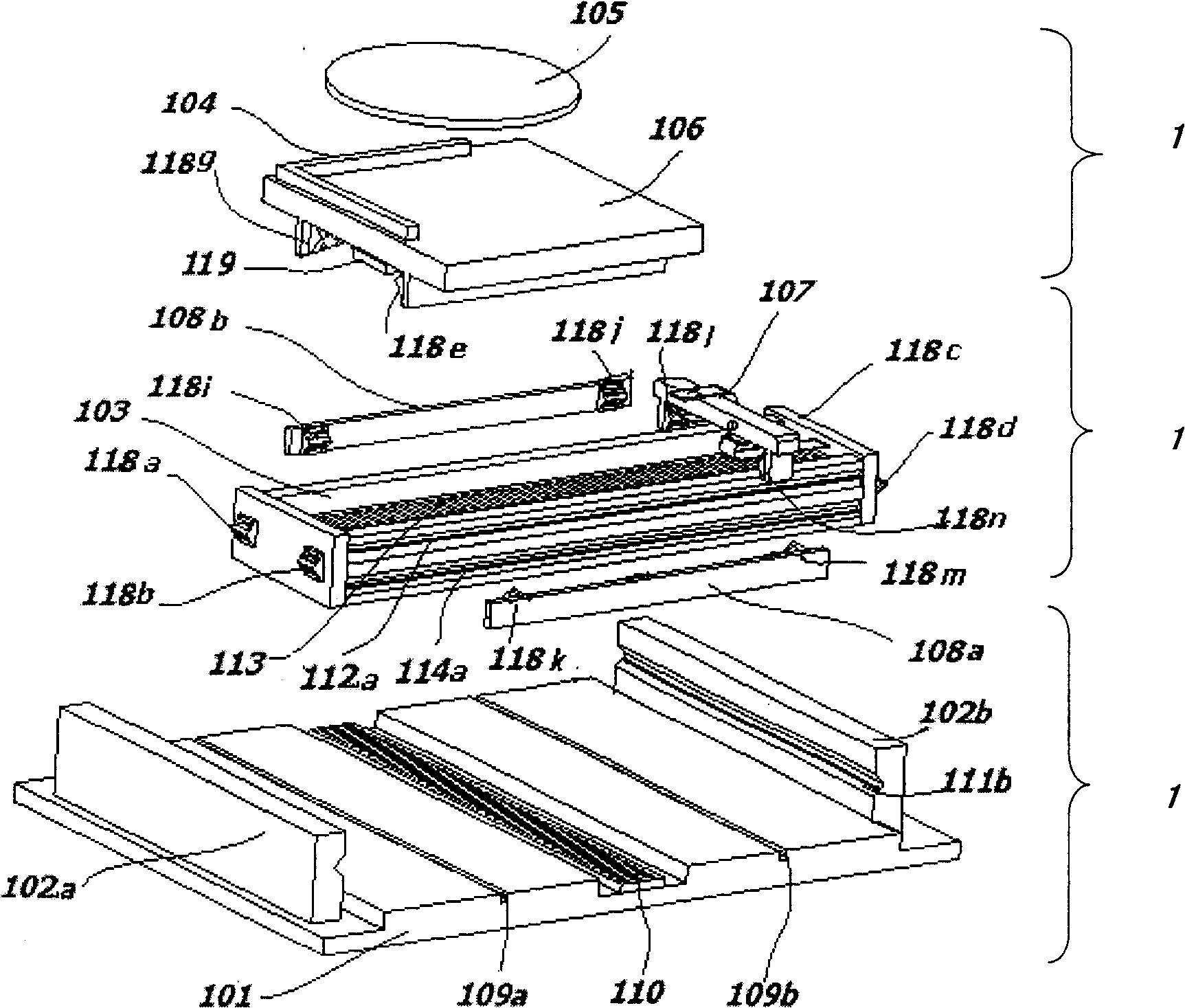

Accurate magnetic suspension worktable for photo etching under extra ultraviolet

InactiveCN100444023CSmooth motionSimple structureSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusLinear motionUltraviolet

The worktable is composed of fine positioning platform module, coarse positioning platform module and base module. Base module is located at bottom most. Being located above the base module, coarse positioning platform module can be moved related to base module along Y direction. Through magnetic suspension guide track, the base module supports the coarse positioning platform module. Being located above the coarse module, fine positioning platform module through magnetic suspension guide track supported by the coarse module can be moved related to the coarse module along X direction. Cable desk, balancing piece and electromagnet can reduce position error and increase rigidity of work head effectively. The invention can realize XY linear motion, and fine motions in 6D: X, Y, Z,ª’X, ª’Y, ª’Z. Features are: simple structure, good rigidity, low energy consumption and high precision. The invention is suitable to photo etching under extra ultraviolet etc.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

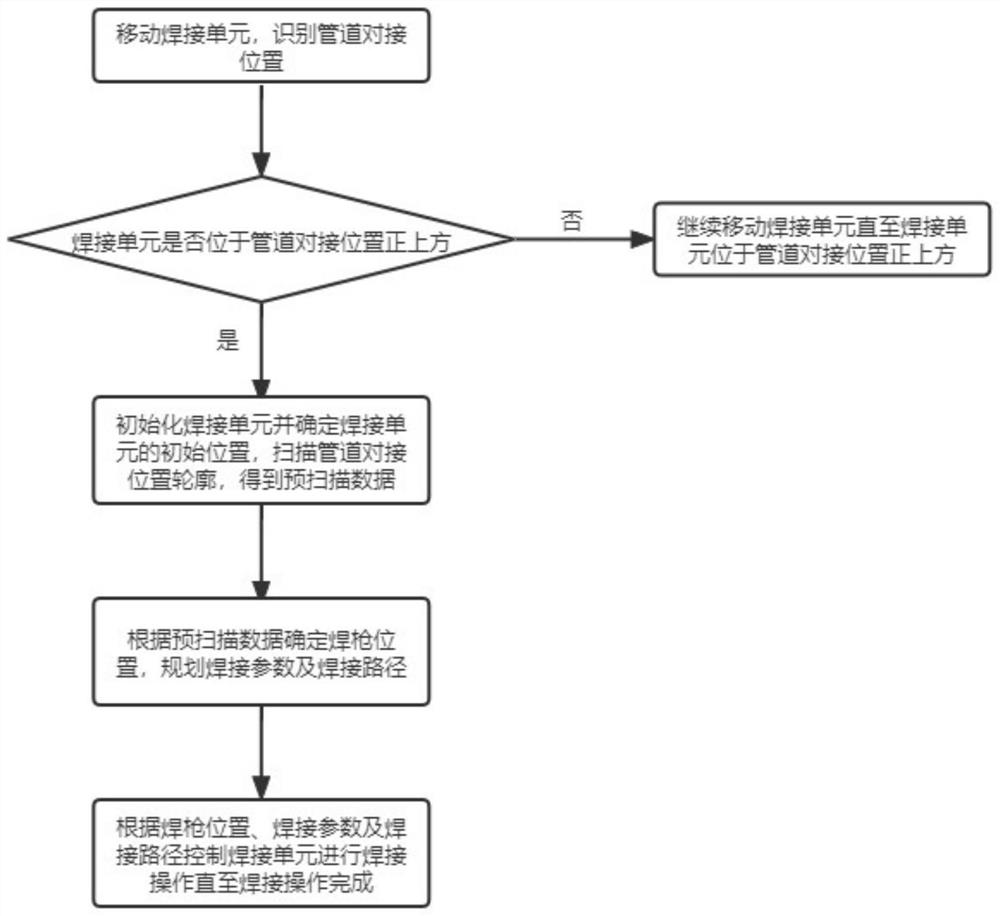

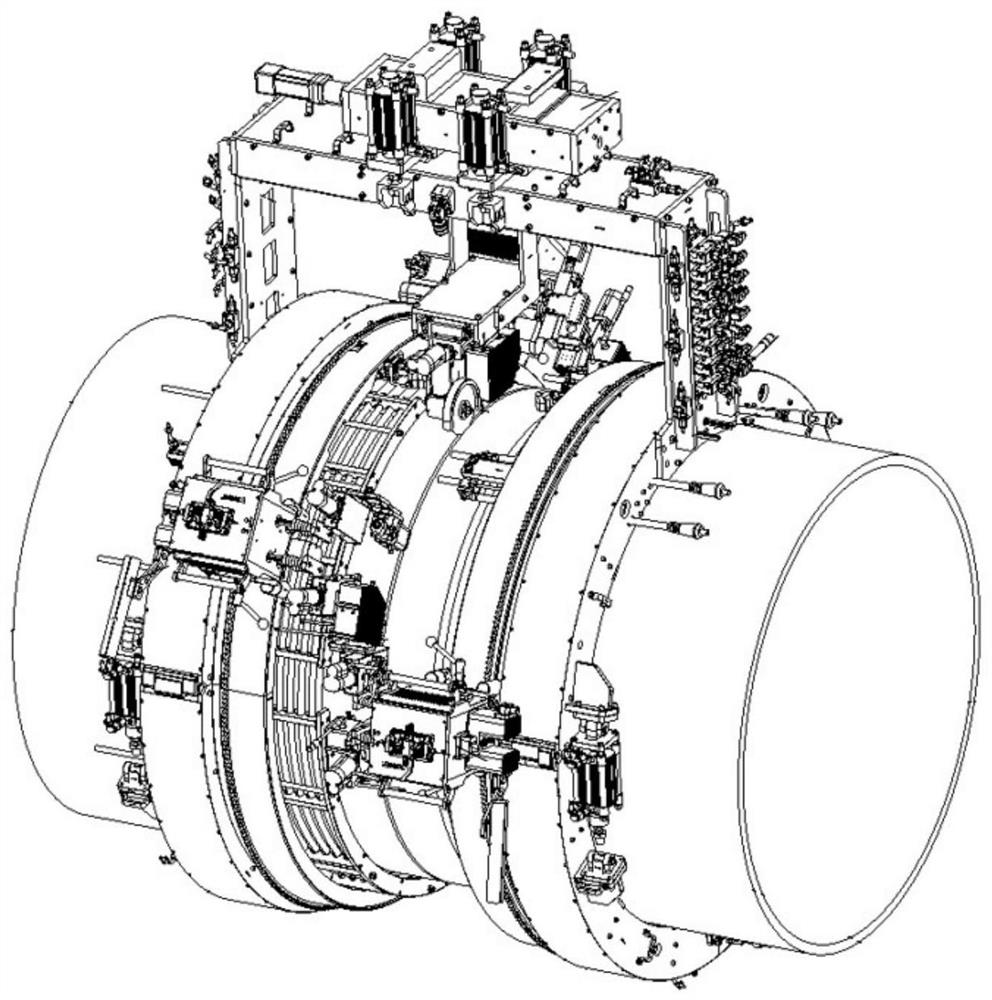

Automatic welding control method

ActiveCN114273754AFully automatedReduce labor costsWelding/cutting auxillary devicesAuxillary welding devicesAutomatic controlButt joint

The invention discloses an automatic welding control method. By moving the welding unit and recognizing the butt joint position of the pipeline, the welding unit is located over the butt joint position of the pipeline, and the labor cost is reduced through the automatic control mode. Initializing the welding unit, obtaining the initial position of the welding unit, scanning the butt joint position of the pipeline, obtaining scanning data, obtaining the position of a welding gun through the scanning data, planning welding parameters and a welding path, and controlling the welding unit to carry out welding operation. The position of the welding gun is obtained through calculation of the sensor, the welding parameters and the welding path are automatically planned through the deep learning network, automation of the whole welding process is achieved, the labor cost is greatly reduced, precision errors caused by manual operation are eliminated, and the welding precision is improved.

Owner:CHENGDU XIONGGU JIASHI ELECTRICAL

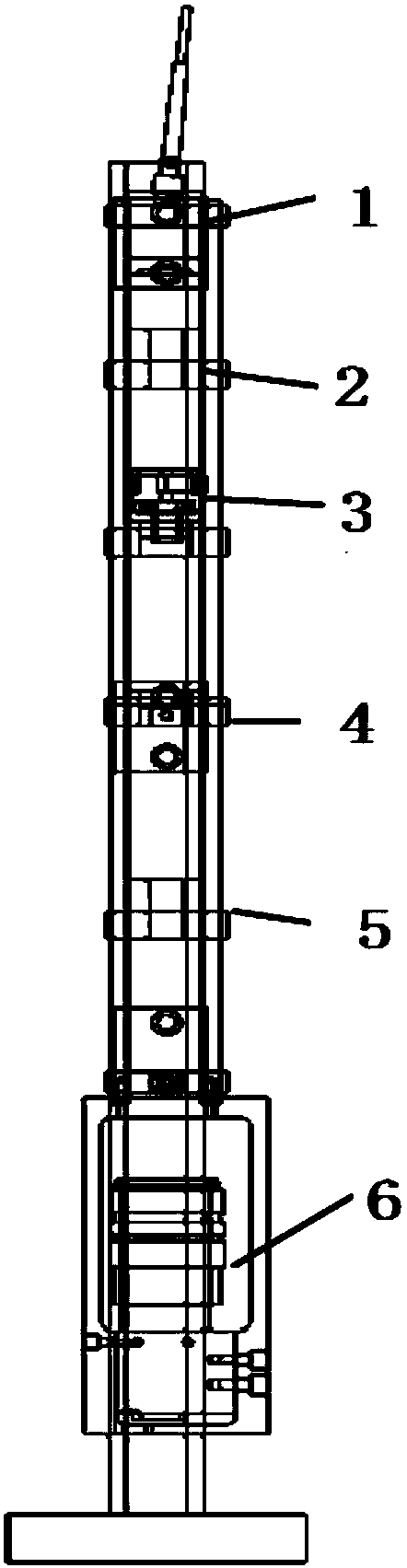

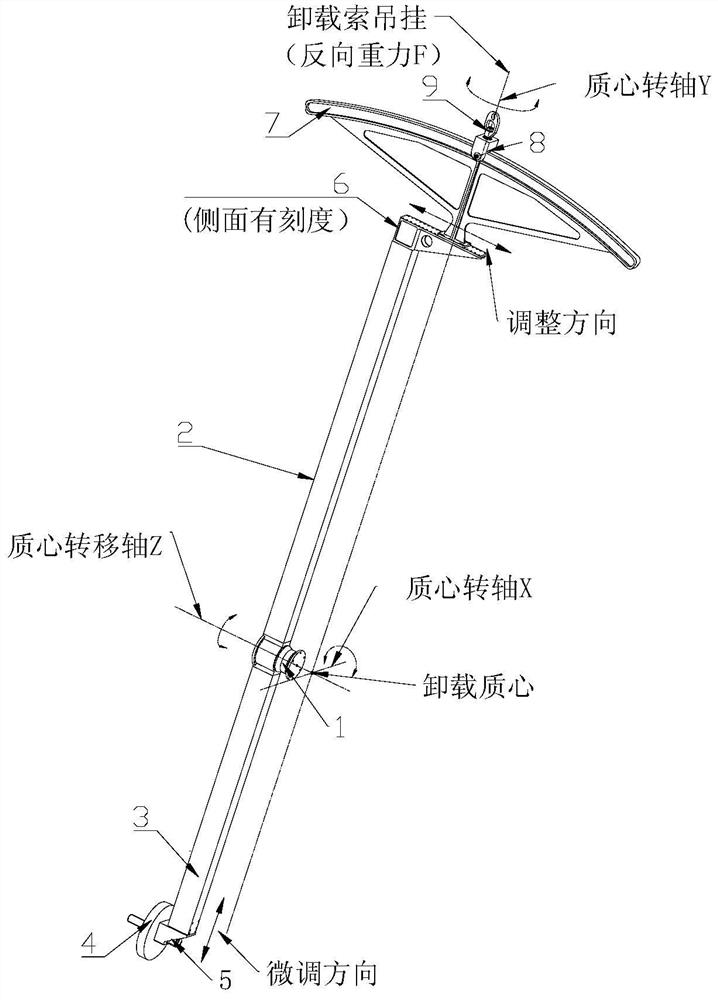

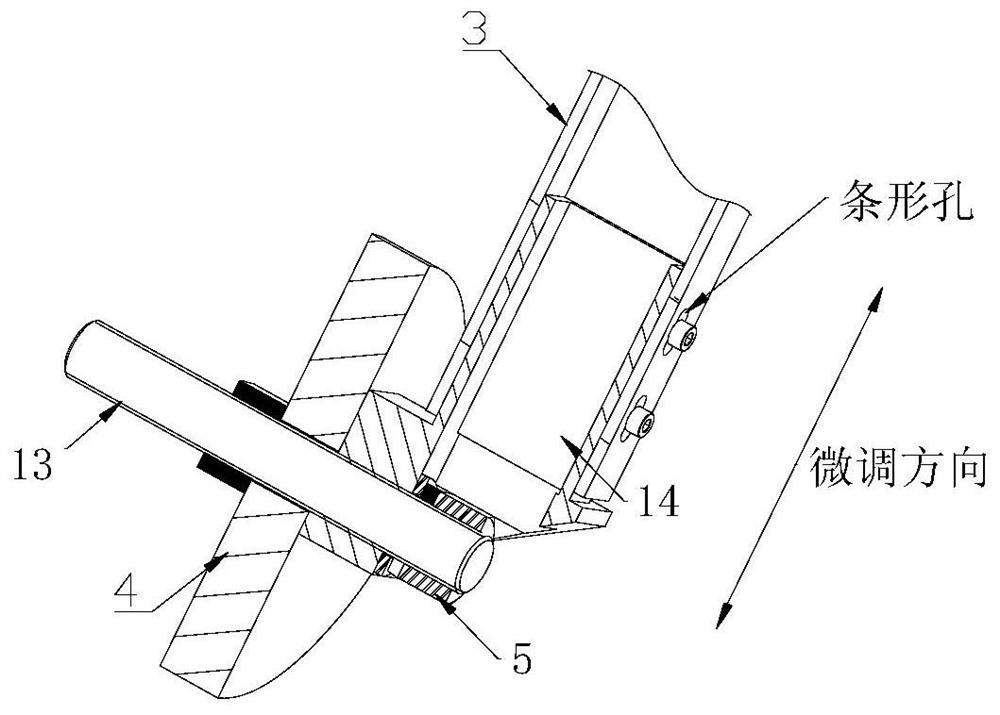

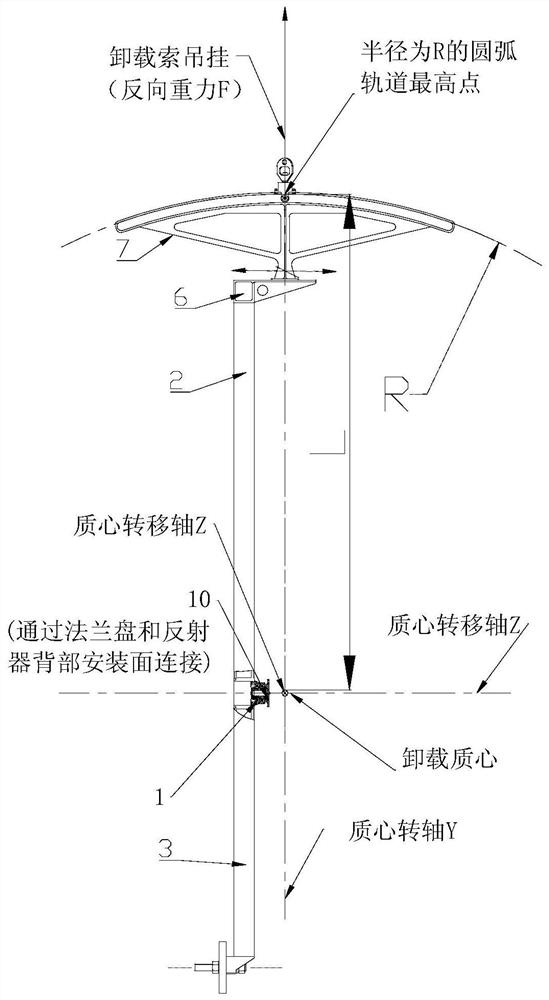

Self-tracking zero-gravity unloading hanging device

ActiveCN112278335AEliminate precision errorsNo design requiredCosmonautic condition simulationsStructural engineeringZero gravity

The invention relates to a self-tracking zero-gravity unloading hanging device which is used for realizing a self-tracking hanging unloading function of an unloaded piece, and realizes that the hanging unloading force of the hanging device automatically tracks and passes through a centroid in the three-dimensional movement process of the unloaded piece through the combined movement of a centroid rotating unit, a rotating hanging ring, an outer circular guide rail and an outer circular sliding trolley, and thus the zero-gravity unloading of the centroid of the unloaded piece is realized. The device is good in universality, easy to install and debug, light in weight and convenient to operate.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

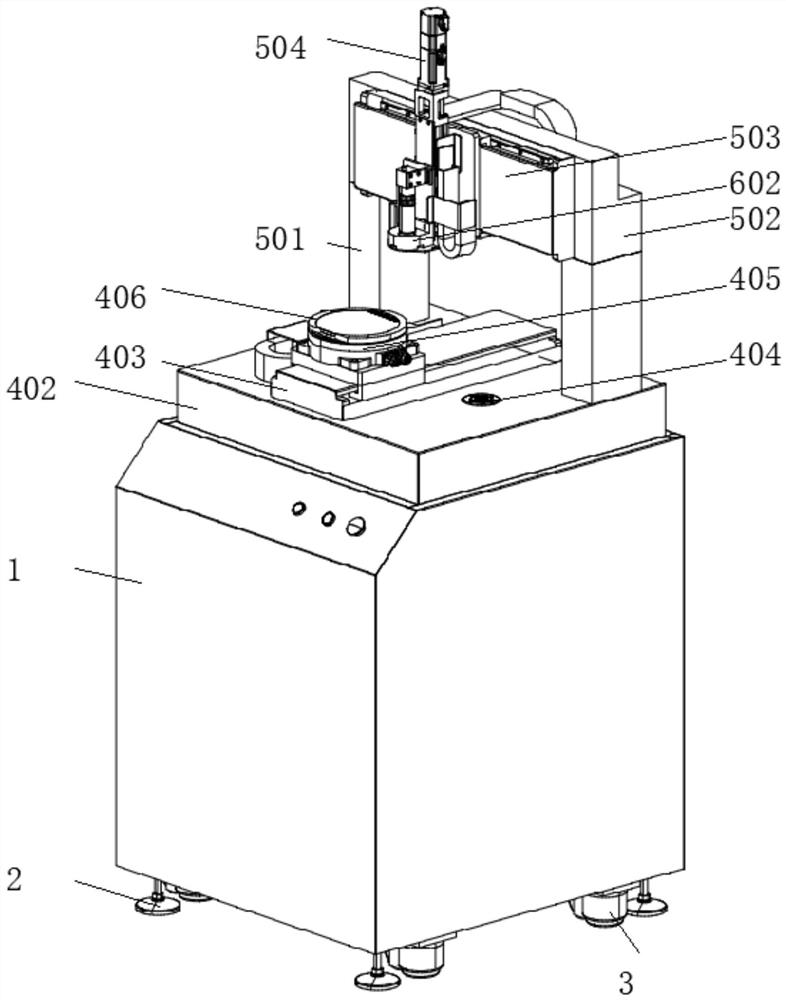

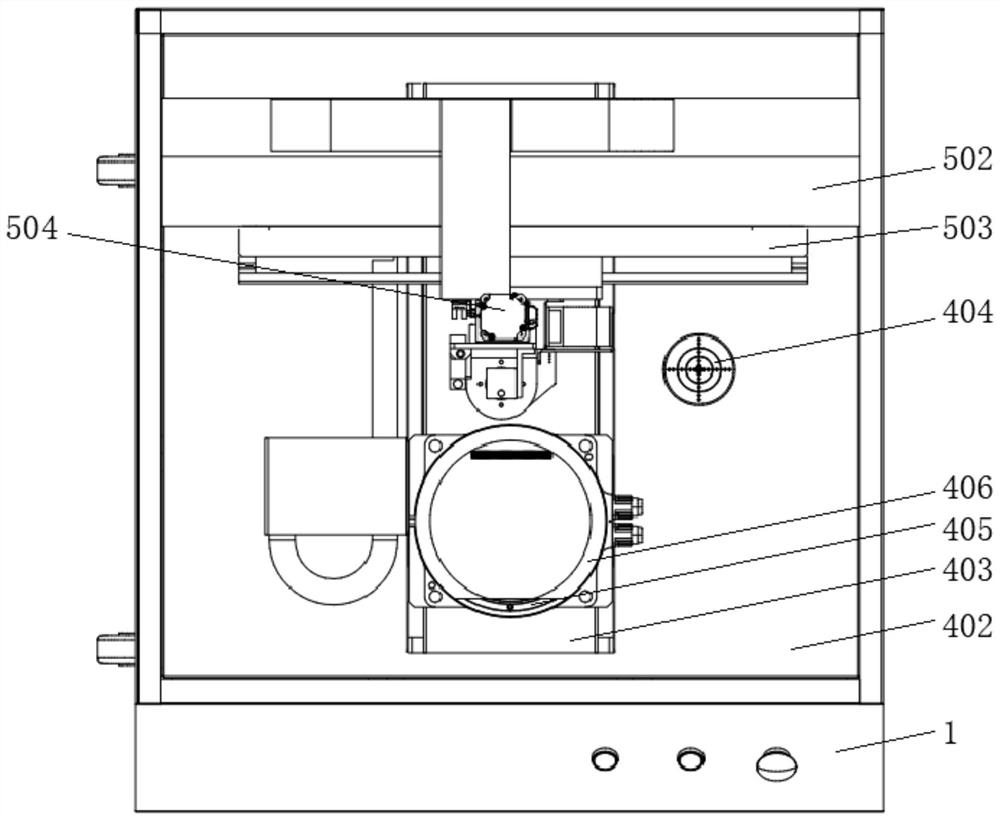

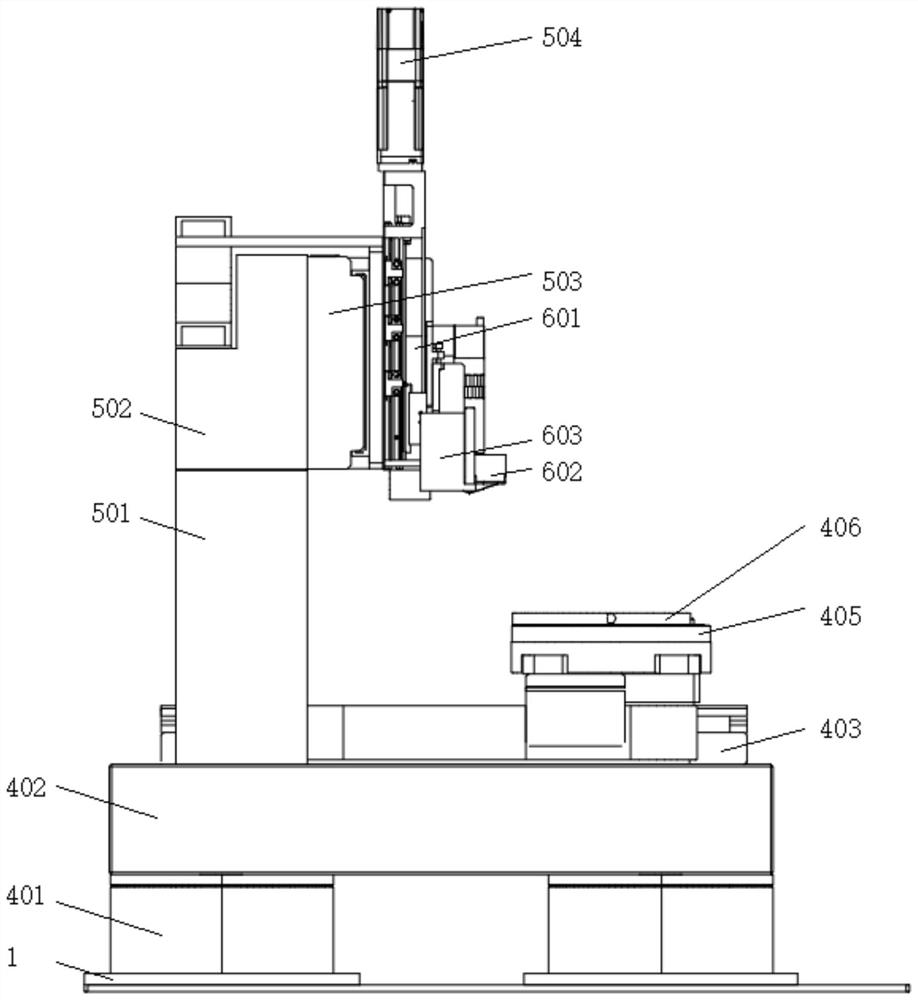

Wafer performance test sample application all-in-one machine

PendingCN113589130AReduce processing efficiencyImprove efficiencyIndividual semiconductor device testingEtchingWafer

The invention relates to the technical field of sample application and testing after wafer etching, particularly discloses a wafer performance testing and sample application all-in-one machine, and solves the problems that in the prior art, procedures such as sample application, drying, testing and sample supplementing of a wafer need to be completed on different machines, so that the wafer needs to be repeatedly positioned, and the wafer processing efficiency and precision are low. The machine comprises a system control cabinet, bearing leveling supporting legs and universal Foma wheels are symmetrically arranged at the bottom of the system control cabinet, and a wafer placing mechanism, a position adjusting mechanism and a performance testing and sample application integrated mechanism are arranged at the top of the system control cabinet; the wafer sample application and performance testing device integrates wafer sample application and performance testing, improves equipment efficiency, reduces equipment investment, realizes automatic operation of sample application and testing work, improves efficiency and quality, has sample application and performance testing functions, realizes automatic sample application according to system setting after performance testing, and improves working efficiency and wafer yield, and the cost caused by defective products is effectively reduced.

Owner:合肥米亚科技有限公司

An automatic lubricating and cooling mechanism for stamping punch

The invention discloses an automatic lubricating and cooling mechanism for stamping male dies. The automatic lubricating and cooling mechanism comprises an oil cup, wherein an oil outlet end of the oil cup is parallel and level to the lower end of a fixing plate and is connected with a first oil tube in parallel; the other end of the first oil tube is connected with one end of an adjusting valve; the other end of the adjusting valve is connected with a second oil tube; the other end of the second oil tube is communicated with an oil storage cavity; a first oil seal and a second oil seal are respectively arranged at two ends of the oil storage cavity; the oil storage cavity is formed in a discharging plate of a die; a punch penetrates in the oil storage cavity; the first oil seal and the second oil seal are arranged between a die head and a die shank of the punch; and the oil pressure between the oil cup and the oil storage cavity keeps balanced by adjusting the adjusting valve. When the punch moves in the up-down direction, a die rod positioned between the die head and the die shank are always soaked in stamping oil in the oil storage cavity partially, and the punch is always lubricated and cooled down by the stamping oil. By the automatic lubricating and cooling mechanism for the stamping male dies, the safety of workers, the efficiency and the quality of the stamping male dies are greatly improved, and the service lives of the stamping male dies are greatly prolonged.

Owner:SEKSUN TECH SUZHOU

A measuring scale, its manufacturing method and using method

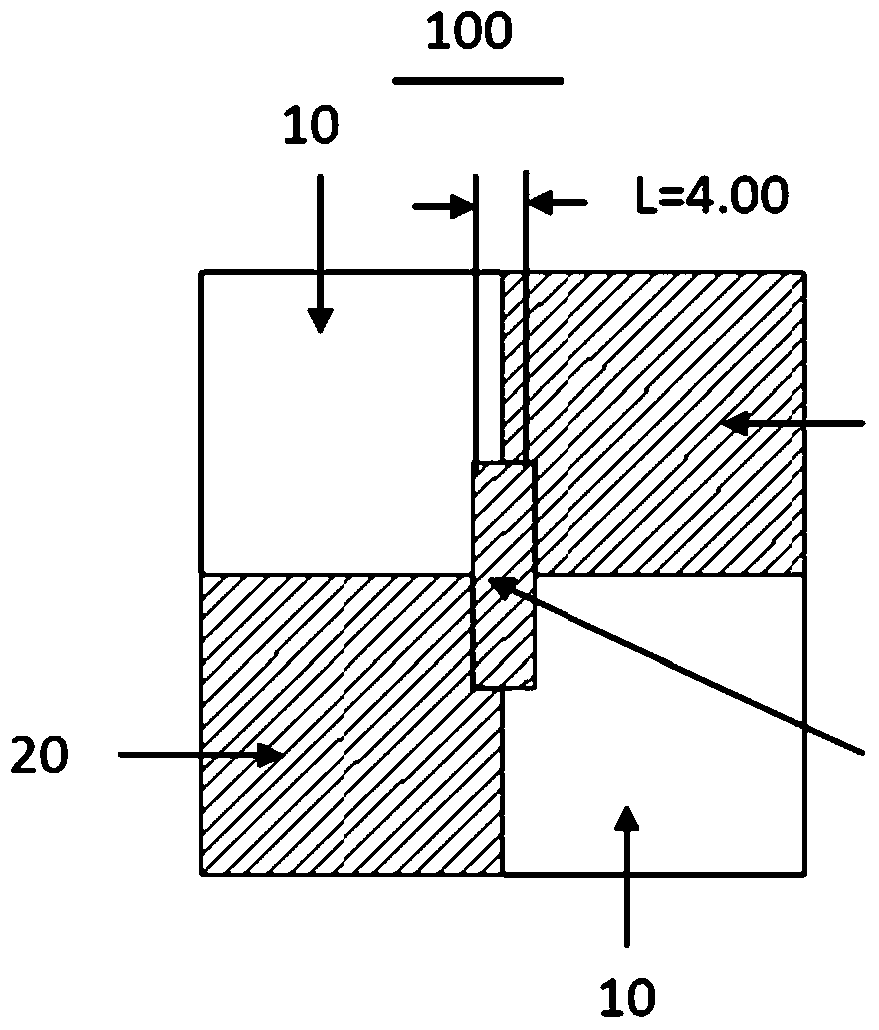

ActiveCN105607308BEliminate precision errorsEliminate errorsNon-linear opticsLine widthAbsolute scale

The invention provides a measurement scale and a manufacturing method and a using method thereof. The measurement scale is located outside a pixel region of an array substrate or a colored film substrate and comprises multiple graphic marks, wherein the graphic marks are formed by the material for any two layers of patterns of the array substrate or the colored film substrate, and deviation values of the line-width unilateral etching amounts of the two patterns and the coincident accuracy between the two patterns are visualized through the measurement scale. By combining with a pattern forming mechanism on the array substrate or the colored film substrate in the manufacturing process, the measurement scale located outside the pixel region is manufactured. The measurement scale adopts a contrasting method rather than an absolute scale for measurement, the accuracy error problem of the absolute scale itself is eliminated, and the specific deviation values of the line-width unilateral etching amounts and the coincident accuracy can be directly read out. The measurement scale can be used for any engineering section before or after etching, device measurement errors are eliminated, and abnormal tracking and test implementation are facilitated.

Owner:NANJING CEC PANDA LCD TECH

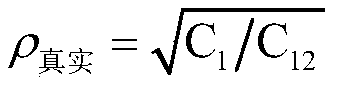

A testing system and method for a digital correlator

ActiveCN107782993BAvoid situations such as self-excitementImprove stabilityElectrical testingIntermediate frequencyFrequency ratio

The invention relates to a digital correlator testing system and method, and belongs to the space microwave remote sensing technical field; the system and method firstly shunt, amplify, filter and phase shift a high frequency signal source, then carry out signal down conversion to needed intermediate frequency, and finally amplify and output in a combined path; the output signal frequency and thesignal source frequency are different, and segmented amplification is employed, thus effectively preventing inter-channel crosstalk and amplifier self excitation conditions, and greatly improving theoutput signal stability. The noise signal phase shift operations of the method are carried out in the high frequency band, thus reducing the signal bandwidth frequency ratio (B / f<<0.05), effectively eliminating the correlation noise signal decorrelation effect, and greatly improving the output signal correlation precision; the method is suitable for all digital correlator tests.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

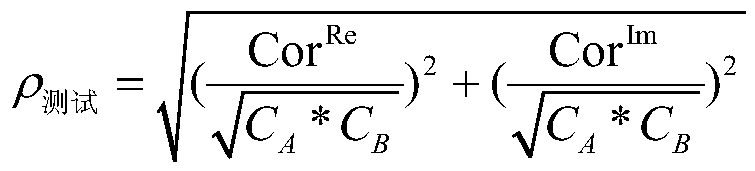

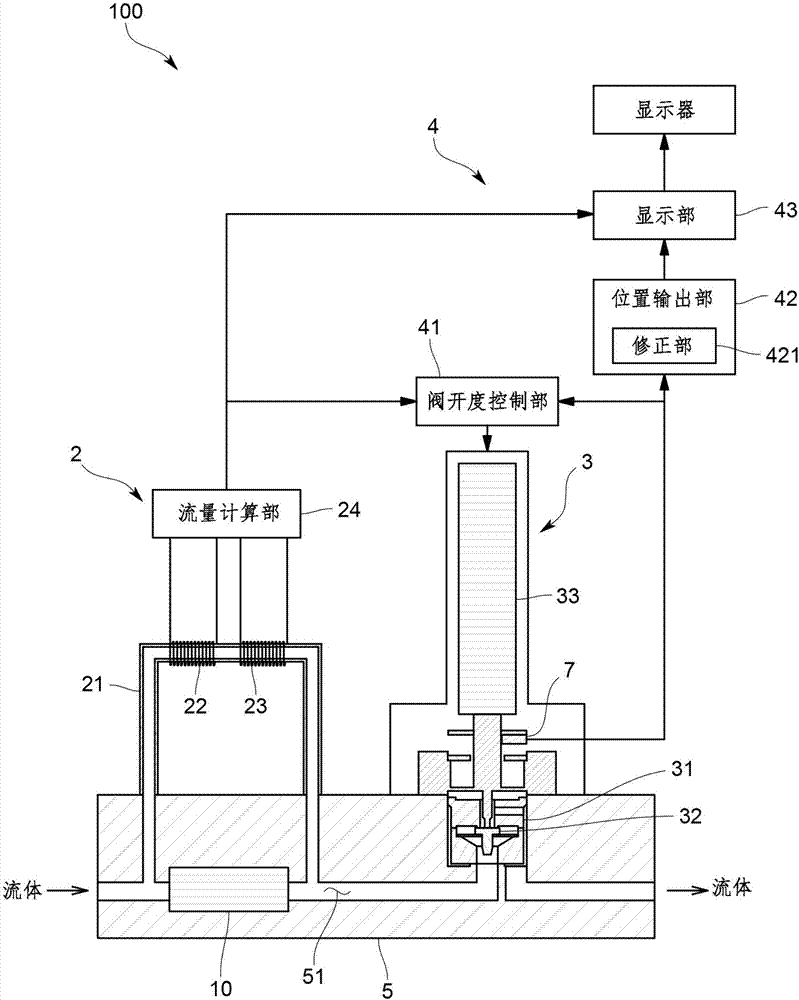

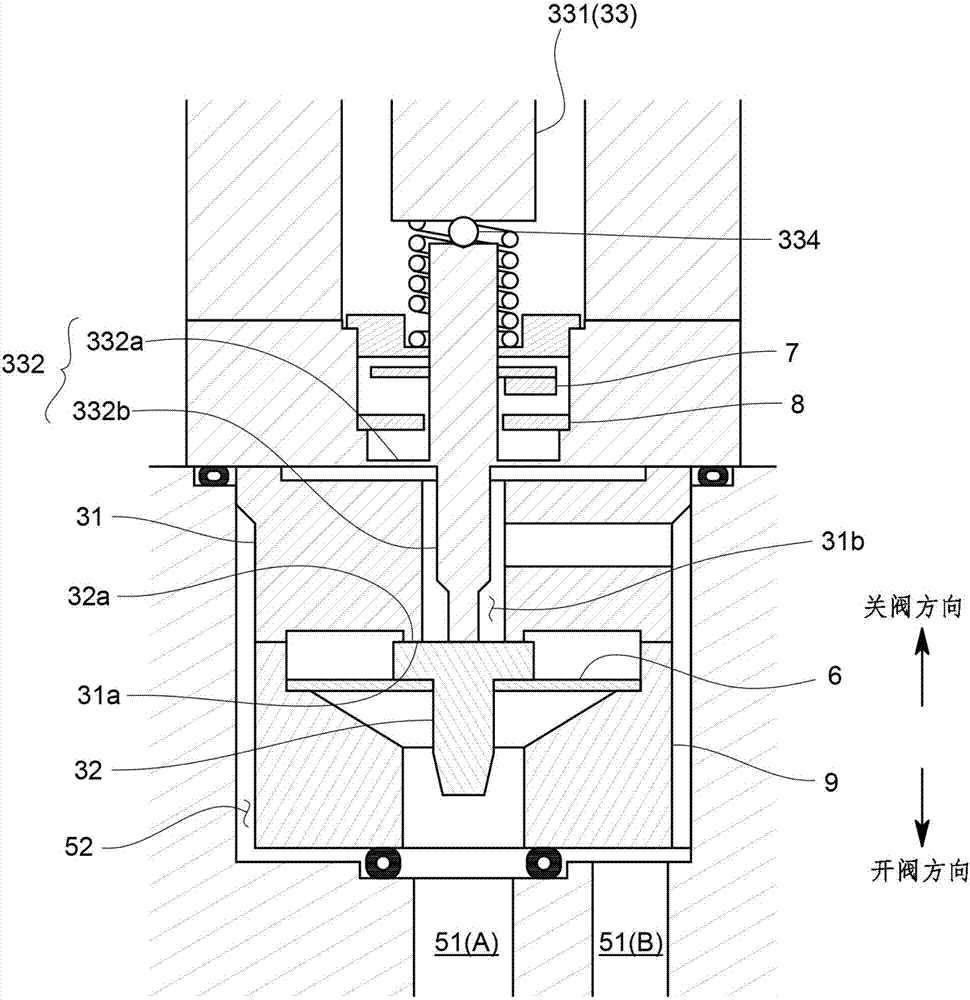

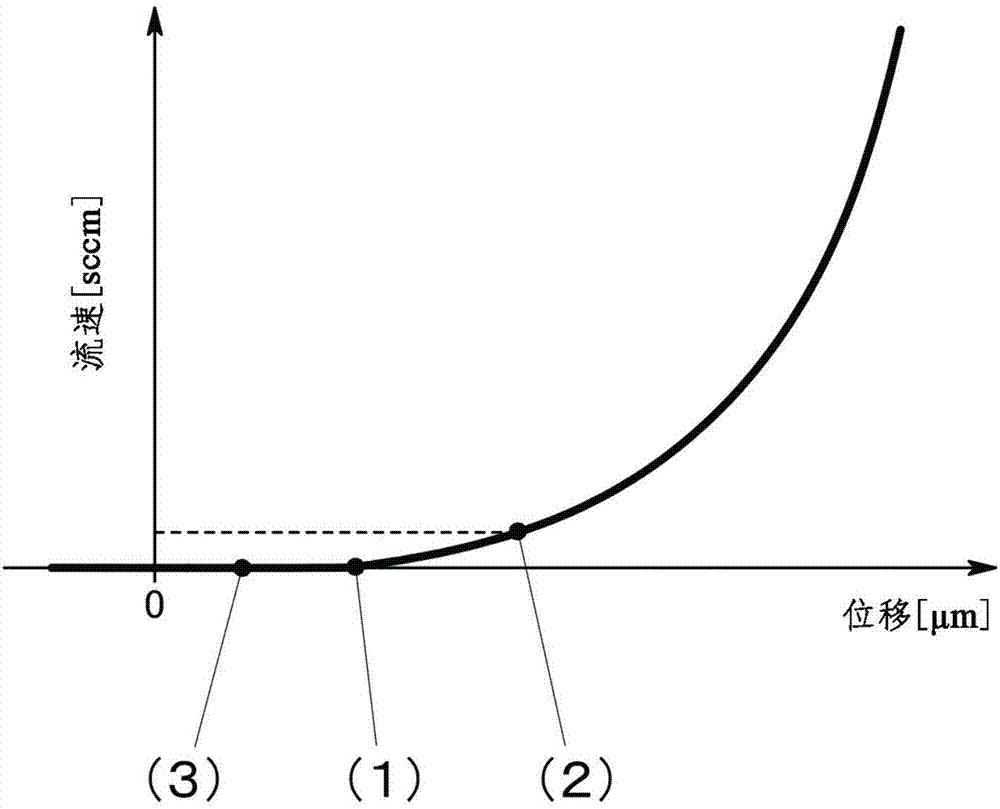

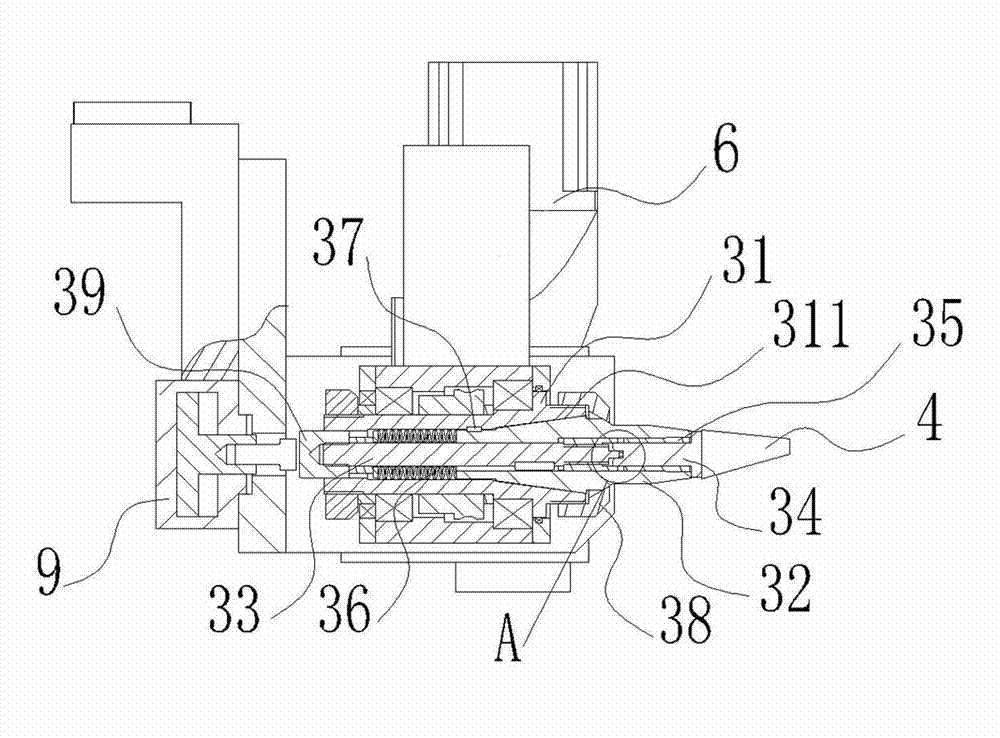

Fluid control valve and control method thereof

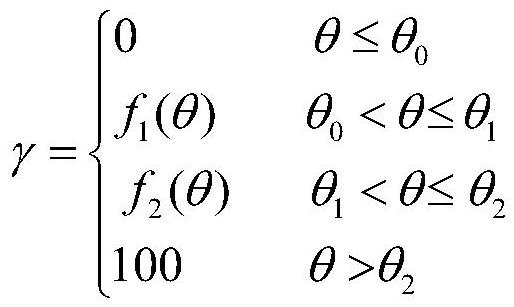

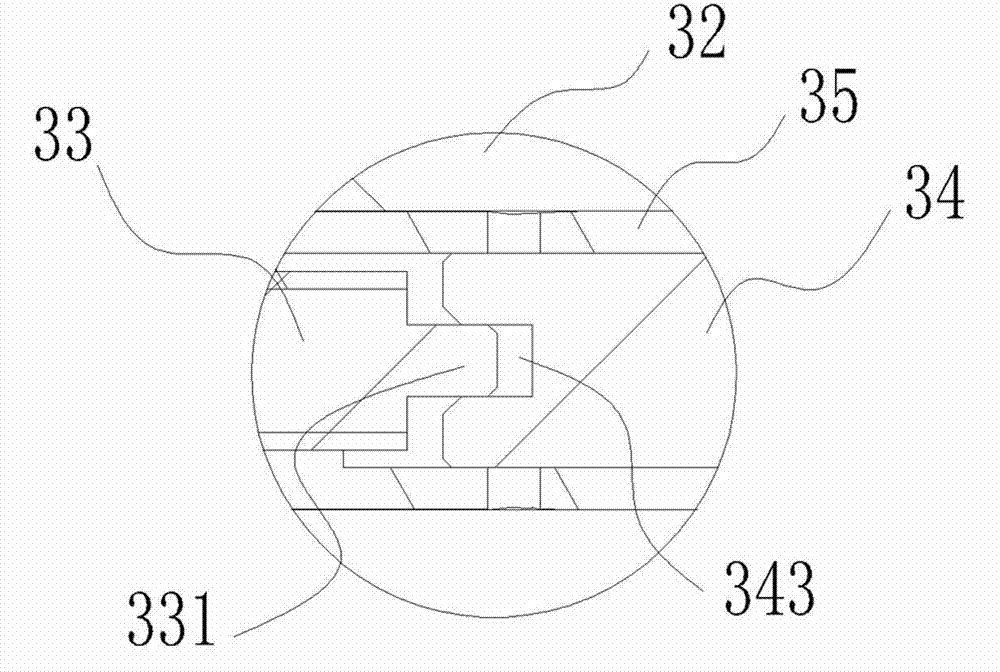

ActiveCN106931221AEliminate precision errorsClear up misunderstandingsOperating means/releasing devices for valvesAltering/correcting law of variationFluid controlEngineering

The present invention provides a fluid control valve that improves usability by eliminating misunderstanding of a user, and a control method thereof. The fluid control valve includes a valve seat (31), a valve body (32) disposed to be approachable to and separable from the valve seat (31), an actuator (33) configured to move the valve body (32) in an approaching or separating direction, a positional information detection part (7) configured to detect a value corresponding to a relative position of the valve body (32) with respect to the valve seat (31), and a position output part (42) configured to set, irrespective of positional information acquired by the positional information detection part (7) at an opening start position of the valve body (32), the opening start position to position zero.

Owner:HORIBA STEC CO LTD

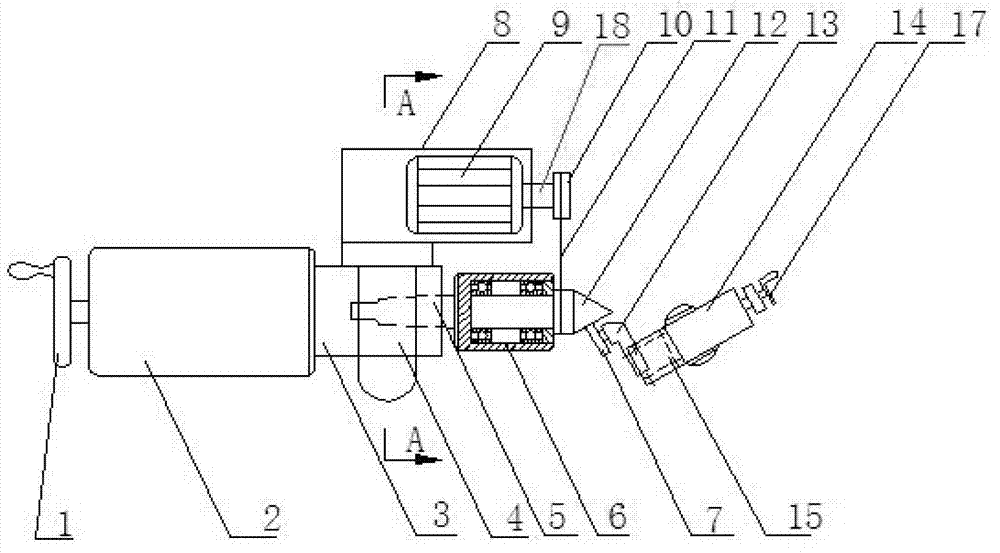

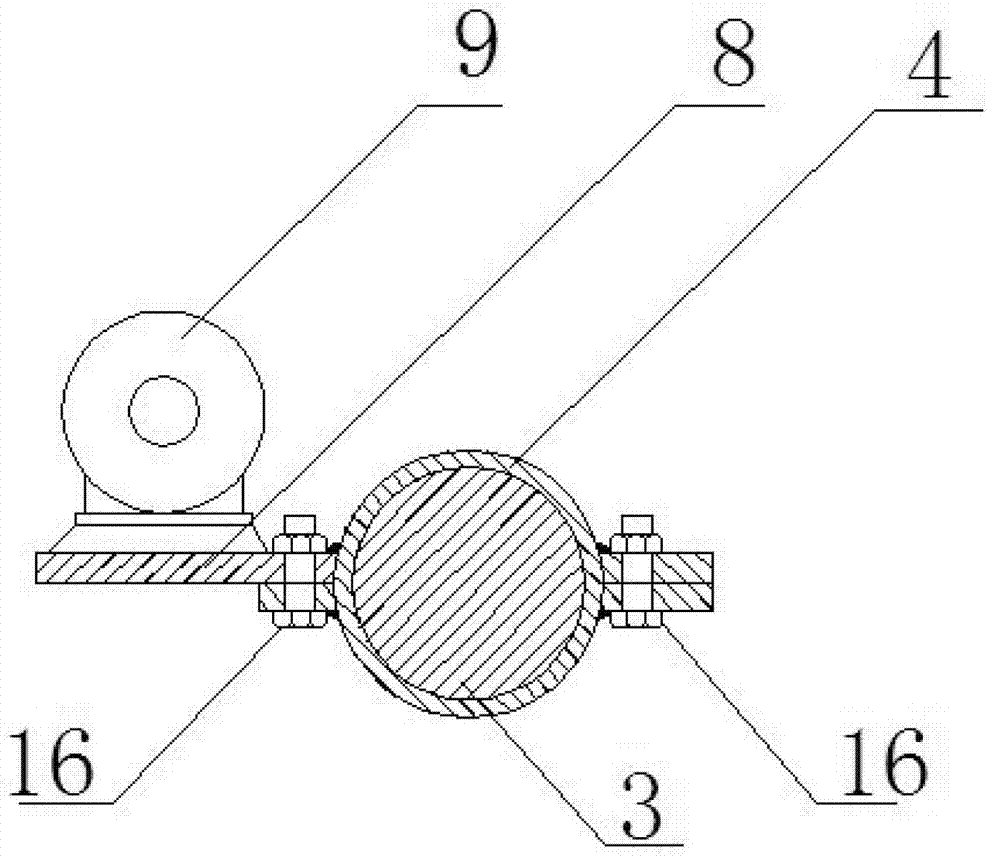

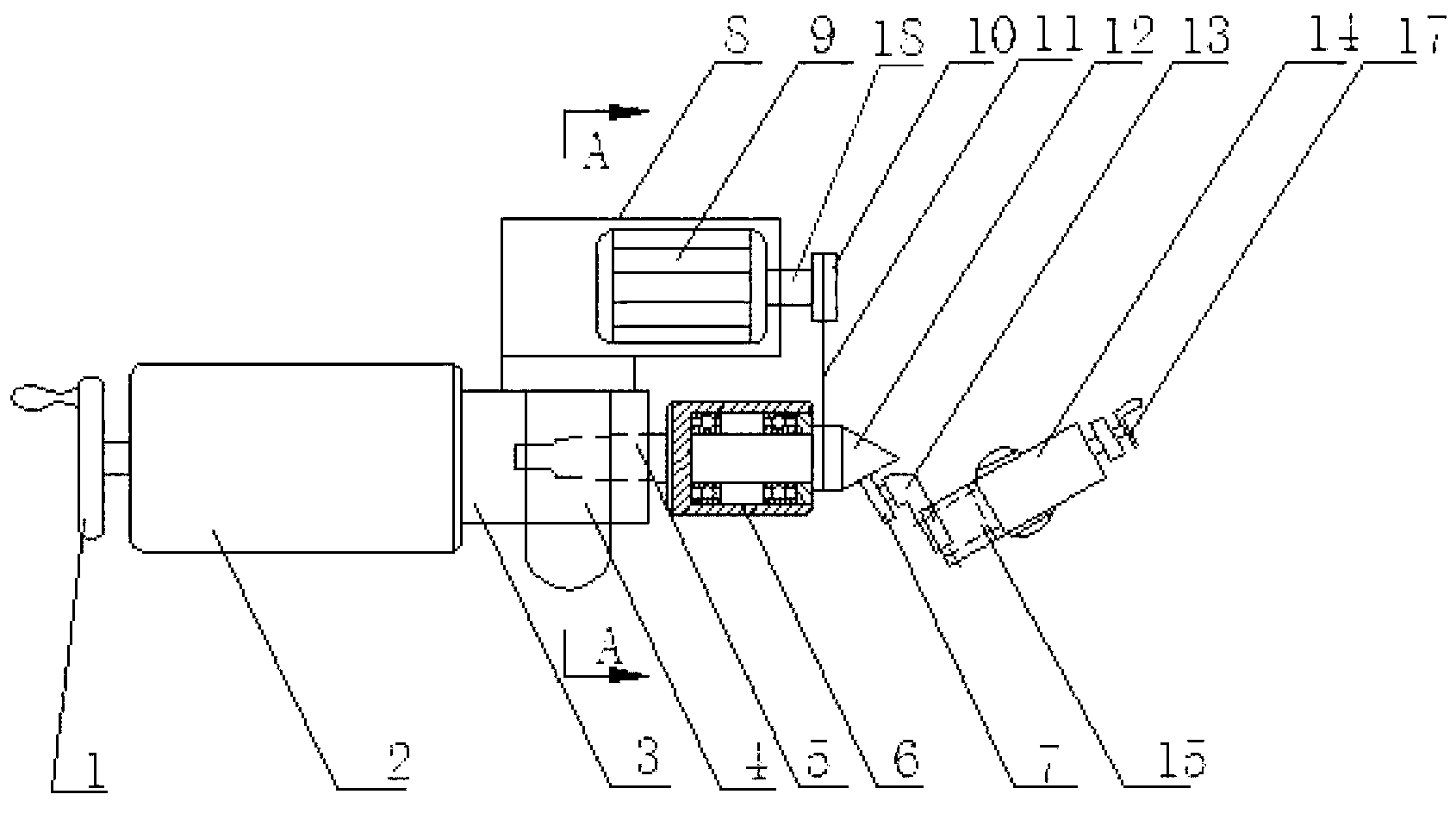

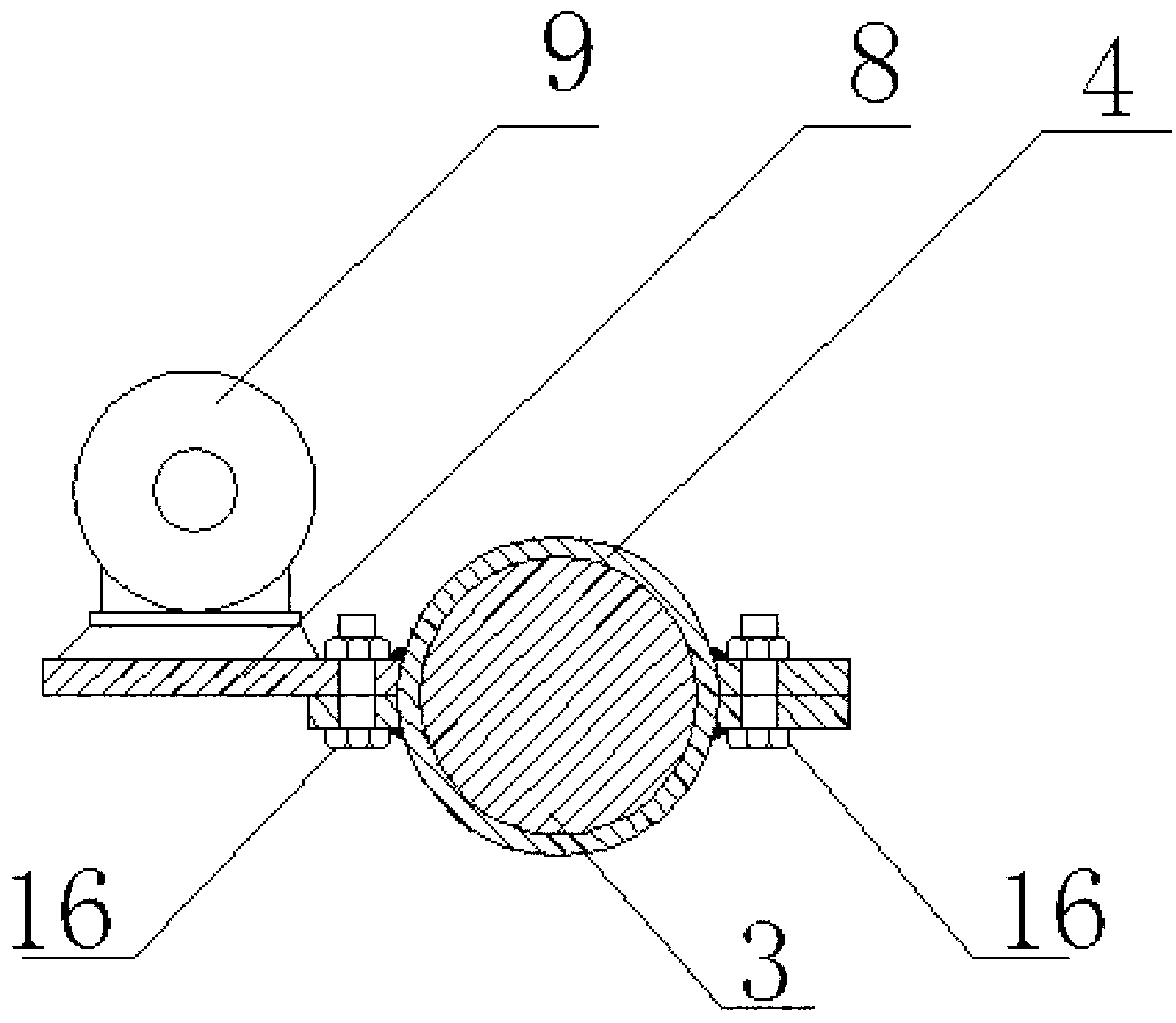

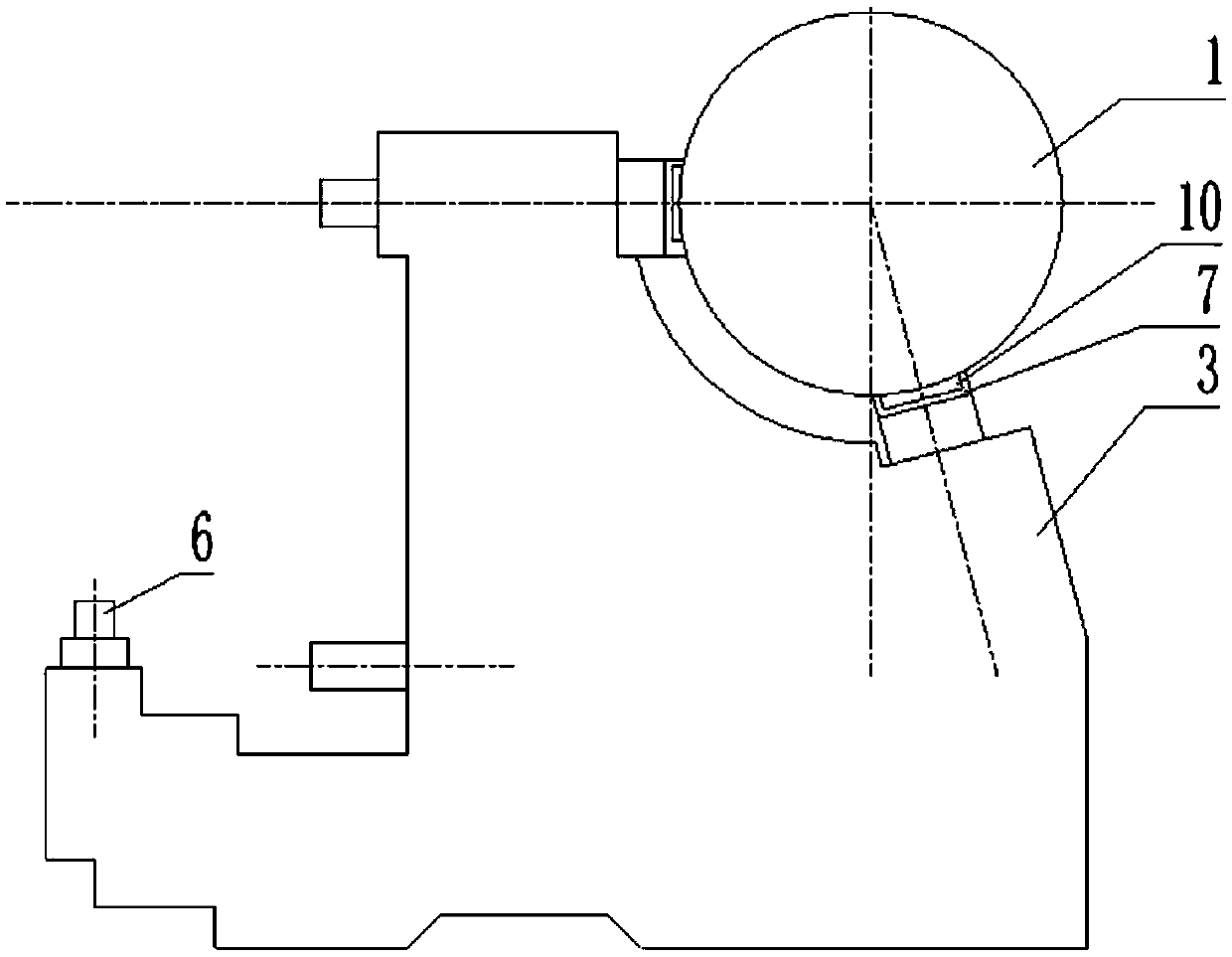

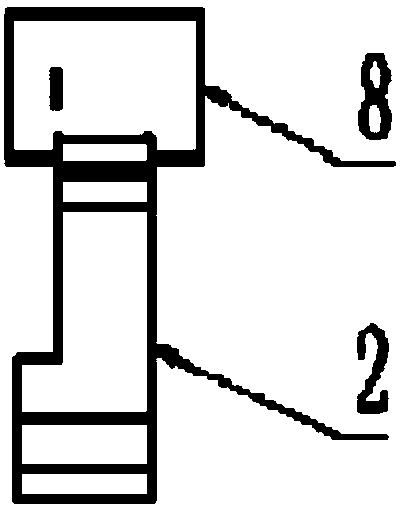

A movable top grinding device and grinding method thereof

InactiveCN103213054BEliminate precision errorsLight structureEdge grinding machinesGrinding drivesCylindrical grindingTailstock

The invention provides a movable centre grinding device, which comprises a lathe tailstock telescopic shaft, a micro grinding machine and a stepless speed regulating motor, wherein the tip of the lathe tailstock telescopic shaft is provided with an axial inner taper hole; the micro grinding machine is arranged on a tool rest of a lathe small carriage; the stepless speed regulating motor is used for driving a movable centre mandrel to rotate; the stepless speed regulating motor is arranged on a horizontal supporting platform; and the horizontal supporting platform is arranged on the outer circle wall of the lathe tailstock telescopic shaft. Due to the adoption of the movable centre grinding device, the axis deviation, caused by rotation under different standards, of the movable centre mandrel is avoided, and accuracy errors caused by grinding with a conventional cylindrical grinding machine is eliminated; and the device has the advantages of simple structure, easiness, practicability, and easiness in installing and adjusting.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

Movable centre grinding device and grinding method thereof

InactiveCN103213054AEliminate the axis deviation of the active center mandrelEliminate precision errorsEdge grinding machinesGrinding drivesAerospace engineeringCylindrical grinding

The invention provides a movable centre grinding device, which comprises a lathe tailstock telescopic shaft, a micro grinding machine and a stepless speed regulating motor, wherein the tip of the lathe tailstock telescopic shaft is provided with an axial inner taper hole; the micro grinding machine is arranged on a tool rest of a lathe small carriage; the stepless speed regulating motor is used for driving a movable centre mandrel to rotate; the stepless speed regulating motor is arranged on a horizontal supporting platform; and the horizontal supporting platform is arranged on the outer circle wall of the lathe tailstock telescopic shaft. Due to the adoption of the movable centre grinding device, the axis deviation, caused by rotation under different standards, of the movable centre mandrel is avoided, and accuracy errors caused by grinding with a conventional cylindrical grinding machine is eliminated; and the device has the advantages of simple structure, easiness, practicability, and easiness in installing and adjusting.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

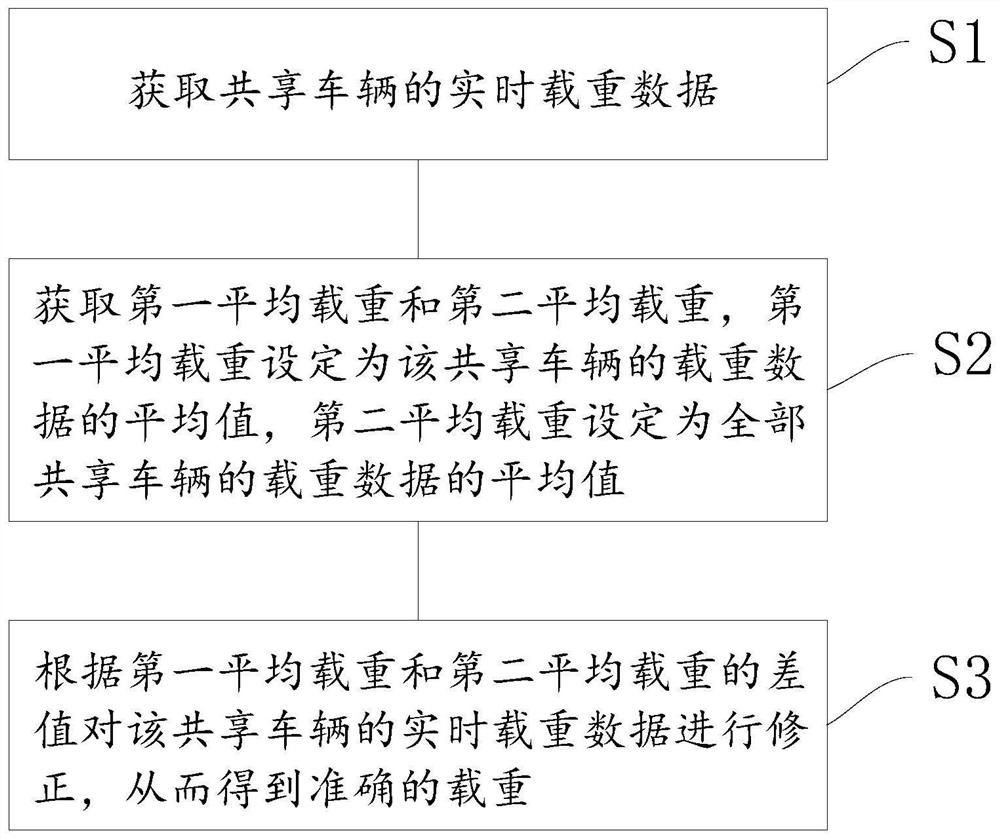

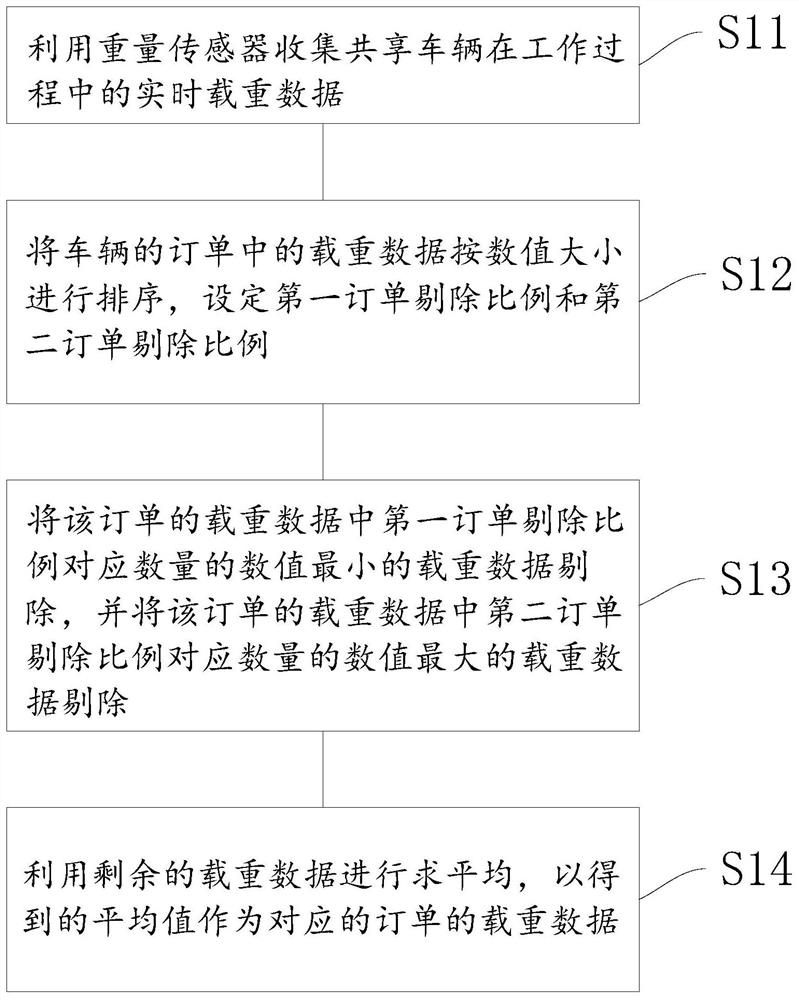

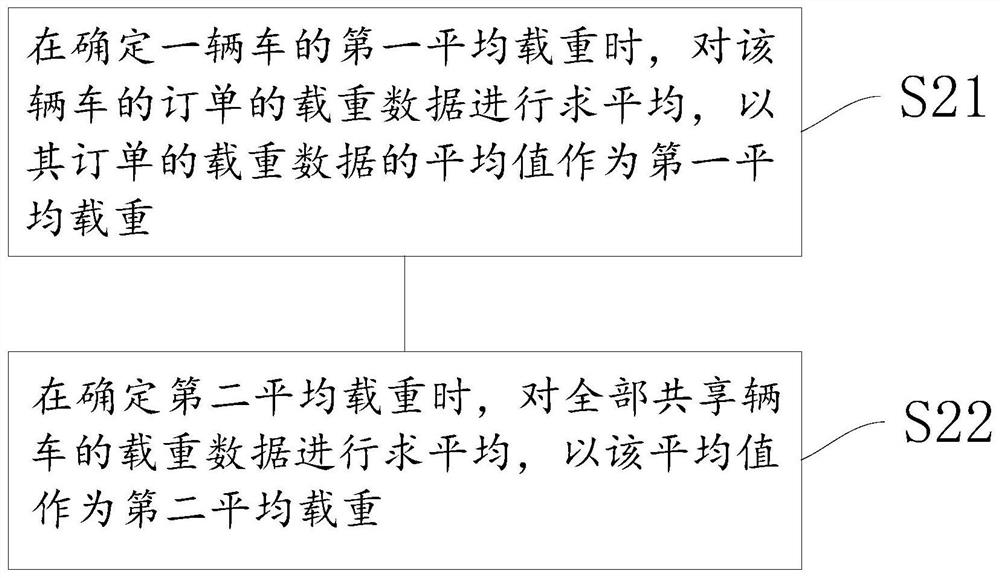

Weight correction method, weight correction system and electronic equipment

ActiveCN113375775AEliminate precision errorsReduce distractionsSpecial purpose weighing apparatusControl engineeringElectronic equipment

The invention discloses a weight correction method, a weight correction system and electronic equipment, and relates to the field of shared vehicles. The weight correction method comprises the steps: acquiring real-time load data of shared vehicles; acquiring a first average load and a second average load, setting the first average load as the average value of the load data of the shared vehicle, and setting the second average load as the average value of the load data of all the shared vehicles; and correcting the real-time load data of the shared vehicles according to a difference value between the first average load and the second average load, so as to obtain an accurate load. The weight correction system and the electronic equipment are used for realizing the weight correction method. The precision error of a weight sensor of the vehicle can be eliminated, so that the load data detected by the vehicle can be corrected to a correct range.

Owner:北京阿帕科蓝科技有限公司

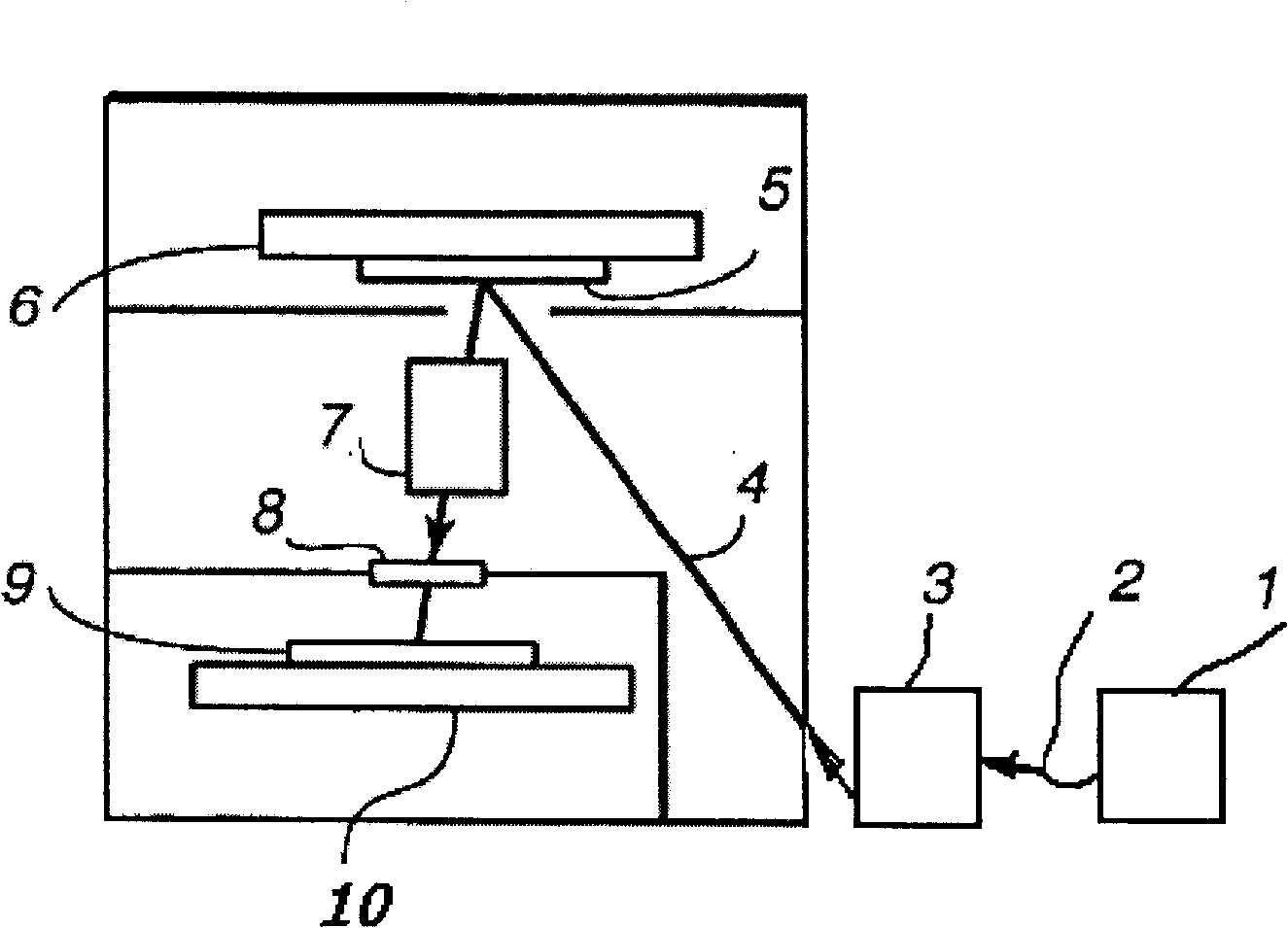

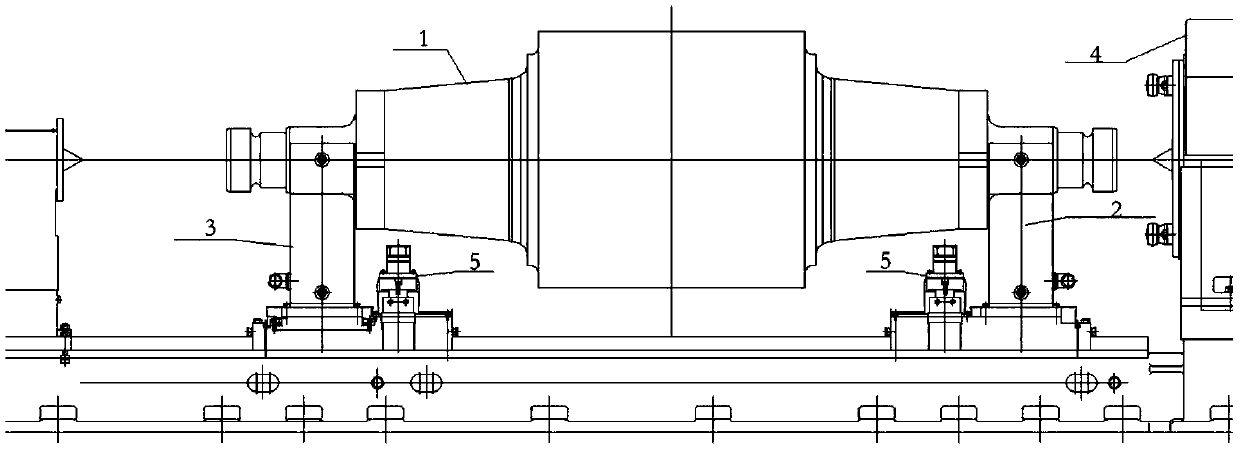

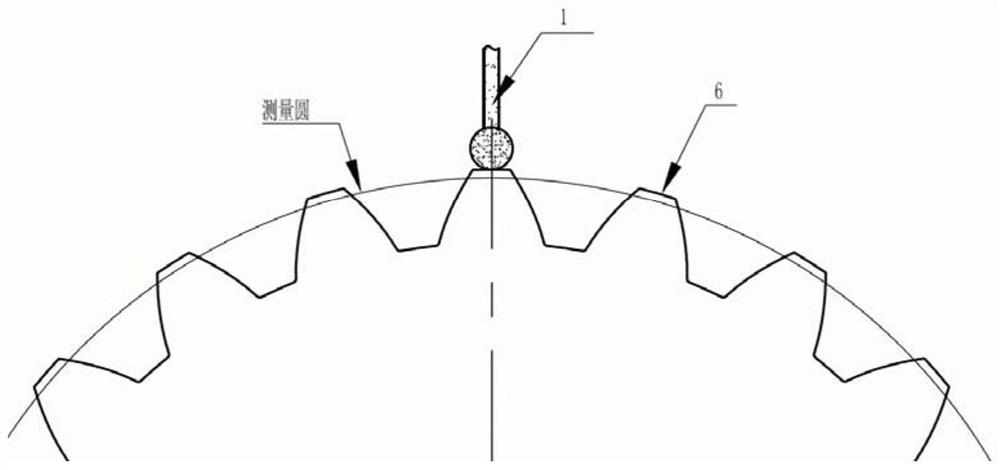

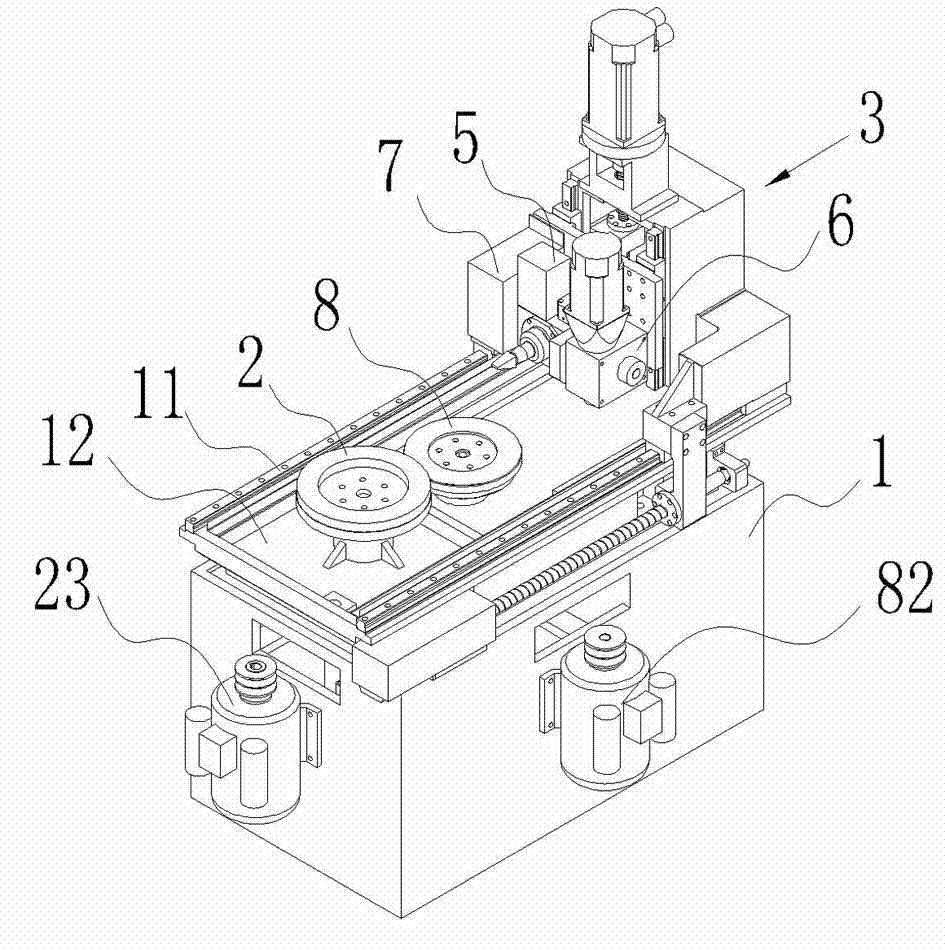

A precision grinding method for rolling mill back-up rolls

ActiveCN107953147BEliminate precision errorsEliminate grinding errorsRevolution surface grinding machinesGrinding work supportsEngineeringRolling mill

The invention provides a rolling mill supporting roll precise grinding method. In the implementing process of the method, a roll grinder (4) is used, a dynamic and static pressing head frame (2) and adynamic and static pressing tail frame (3) are used for supporting a supporting roll (1), one end of the supporting roll (1) is machined firstly till the target diameter is reached, and then the supporting roll (1) is turned around to enable the other end of the supporting roll (1) to be machined till the target diameter is reached; and through the dynamic and static pressing head frame (2) and the dynamic and static pressing tail frame (3), the position, machined to be the target diameter, of the supporting roll (1) is supported, and then axial diameter grinding of other positions is conducted. According to the rolling mill supporting roll precise grinding method, one end of the supporting roll is machined firstly, then the supporting roll is turned around to enable the other end of thesupporting roll to be machined, and through the dynamic and static pressing head frame and the dynamic and static pressing tail frame, the position, machined to be the target diameter, of the supporting roll is supported; and through the grinding mode, grinding errors caused by supporting axial diameter original manufacturing errors can be eliminated, so that the requirement for high-precision grinding is met, and meanwhile the influence of supporting axial diameter sizes and the form and location tolerance of a traditional grinding mode on the grinding precision is eliminated.

Owner:TIANJIN HEAVY EQUIP ENG RES +1

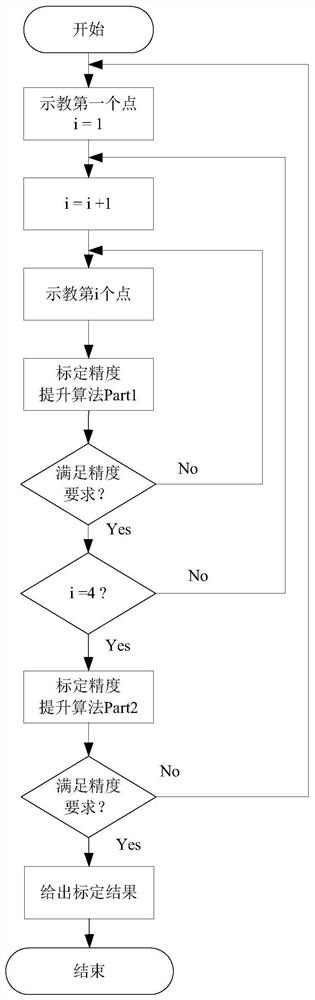

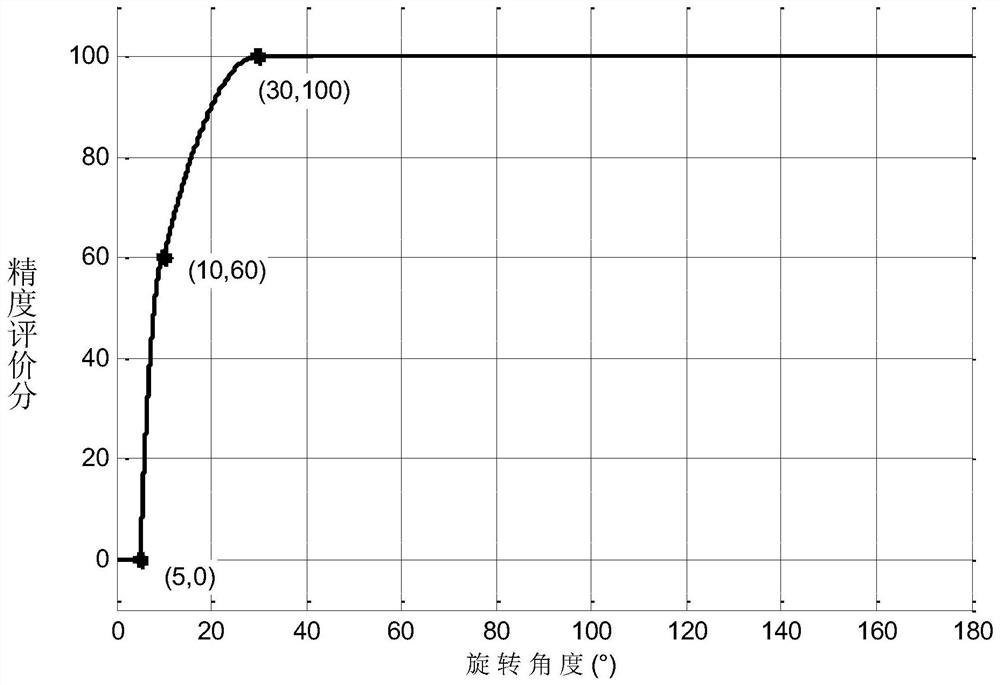

A method to improve the calibration accuracy of industrial robot tool coordinate system

ActiveCN109465831BConvenient teachingEliminate precision errorsProgramme-controlled manipulatorControl engineeringProcess engineering

The invention discloses a method for improving the calibration accuracy of an industrial robot tool coordinate system, which belongs to the field of industrial robot application control. In the common "four-point method" tool coordinate system calibration process, this method gives an accuracy evaluation for each point to be calibrated. When the accuracy meets the requirements, the next calibration point can be calibrated, and all calibration points are recorded. Finally, an overall accuracy evaluation is given to the final calibration results. This method is convenient for the user to teach a reasonable calibration point, eliminates the human error caused by the user during the calibration process, and obtains a high-precision tool coordinate system calibration result, thereby eliminating the trajectory tracking caused by the inaccurate tool coordinate system calibration Motion problems such as low precision. The tool coordinate system calibration lifting algorithm proposed by the invention does not need to add any calibration device, and the operation is simple and convenient.

Owner:NANJING ESTUN ROBOTICS CO LTD

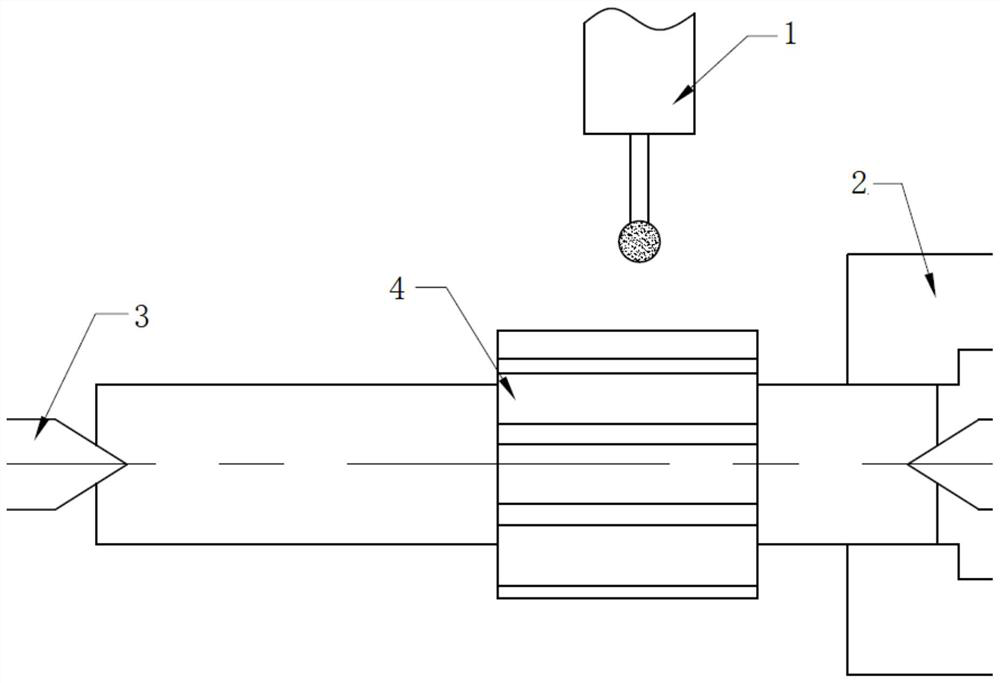

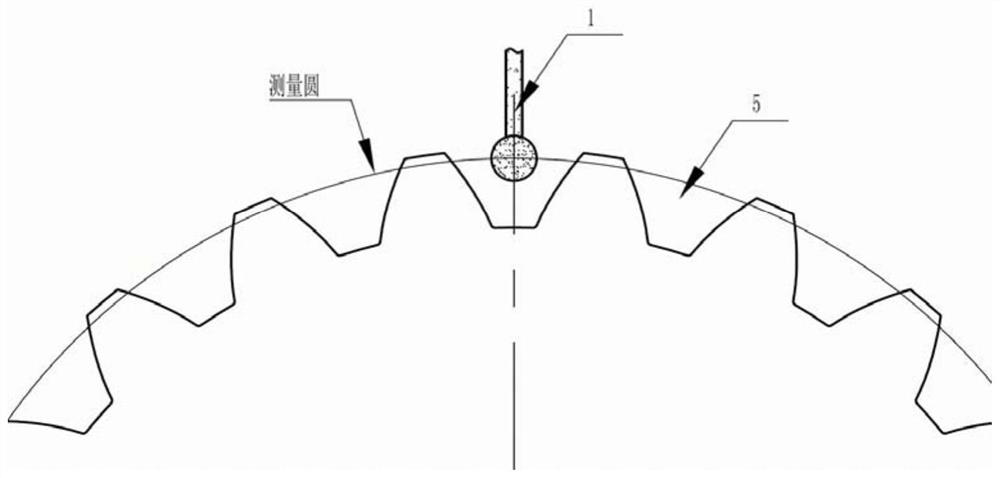

Tooth profile positioning method and tooth profile positioning control system

ActiveCN113029060AImprove machining accuracyLow production costMeasurement devicesGear teethGear wheelEngineering

The invention belongs to the field of tooth profile measurement, and discloses a tooth profile positioning method and system. The measuring head is controlled to carry out directional detection, and a series of judgment and conversion are carried out on detection data, so that the central position of the tooth groove is accurately calculated. By means of the tooth profile positioning method, the gear machining precision can be greatly improved, a special positioning tool does not need to be designed, and the machining process flexibility is improved. For batch manufacturing of gear workpieces, the tool investment cost can be greatly reduced, the tooth profile positioning time is shortened, and the machining efficiency is improved.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

A method for installing an independent cargo tank of a cargo ship

Owner:HUBEI OCEAN ENG EQUIP RES INST CO LTD

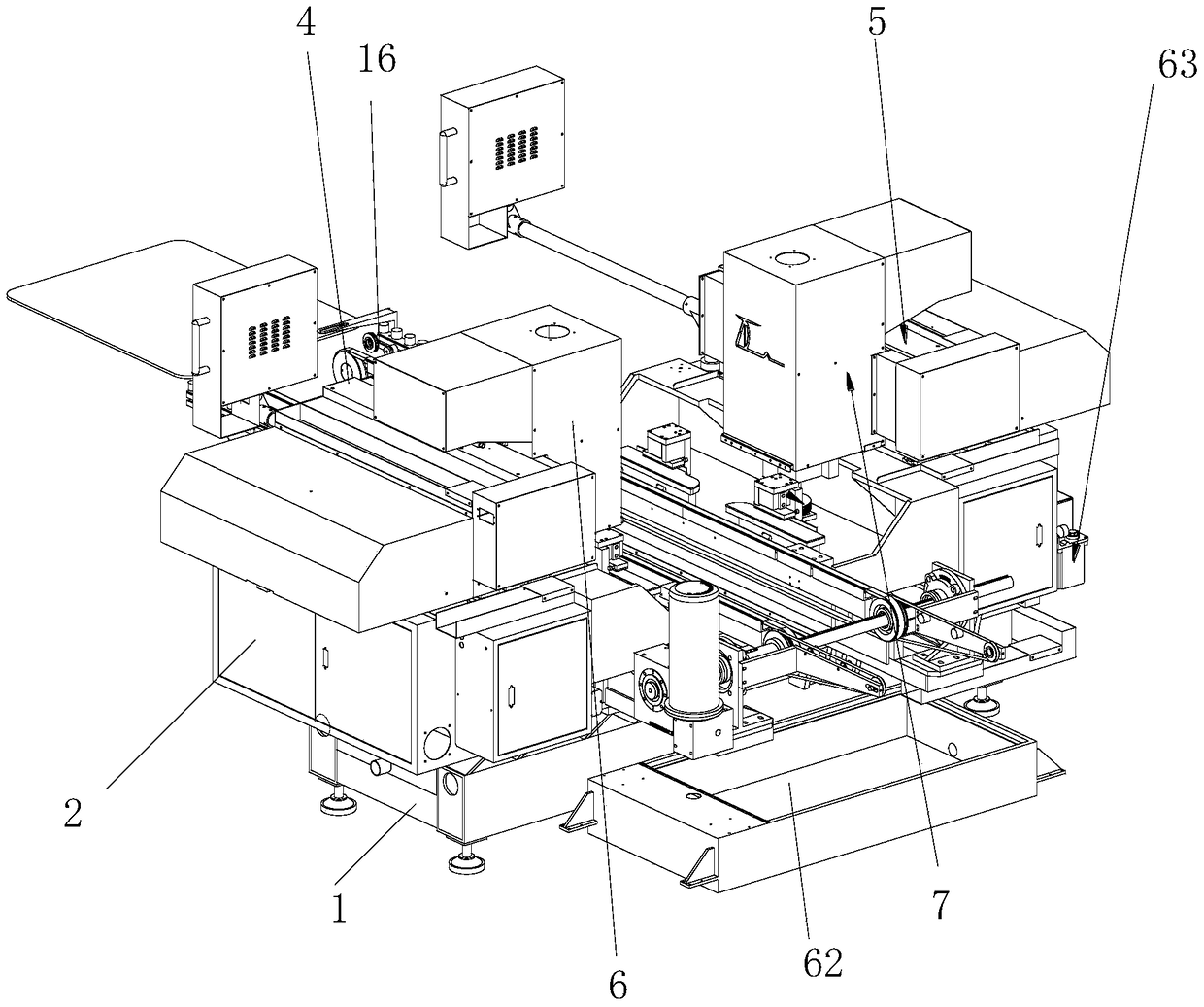

Bilateral connection intelligent chamfering machine

ActiveCN105643390BHigh precisionHigh sensitivityEdge grinding machinesGrinding carriagesProduction lineFrame based

The invention relates to the technical field of glass chamfering machines, in particular to a double-side in-line intelligent chamfering machine which comprises a main machine frame base, wherein a main machine frame and an accessary machine frame are oppositely arranged on the main machine frame base; cross beams slide on the main machine frame and the accessary machine frame in Y-axis directions respectively; X-axis sliding tables are arranged on the cross beams; spindle motors are mounted on Z-axis sliding tables; the Z-axis sliding tables are mounted on the X-axis sliding tables; polishing mechanisms are mounted on the spindle motors; a glass conveying hold-down mechanism is arranged on the main machine frame base, and comprises an initial positioning mechanism, a front synchronizing wheel up-down moving mechanism, a glass tooling fixture, a glass hold-down mechanism and a back synchronizing wheel moving mechanism; and CCD camera positioning systems, operation panels and electric control cabinets are arranged on the main machine frame and the accessary machine frame respectively. The double-side in-line intelligent chamfering machine has the advantages that the whole working process is intelligent completely, no manual operation is required, the production efficiency is greatly improved, the cost is reduced, and various automatic production lines can be assembled as required.

Owner:东莞市众度机械设备有限公司

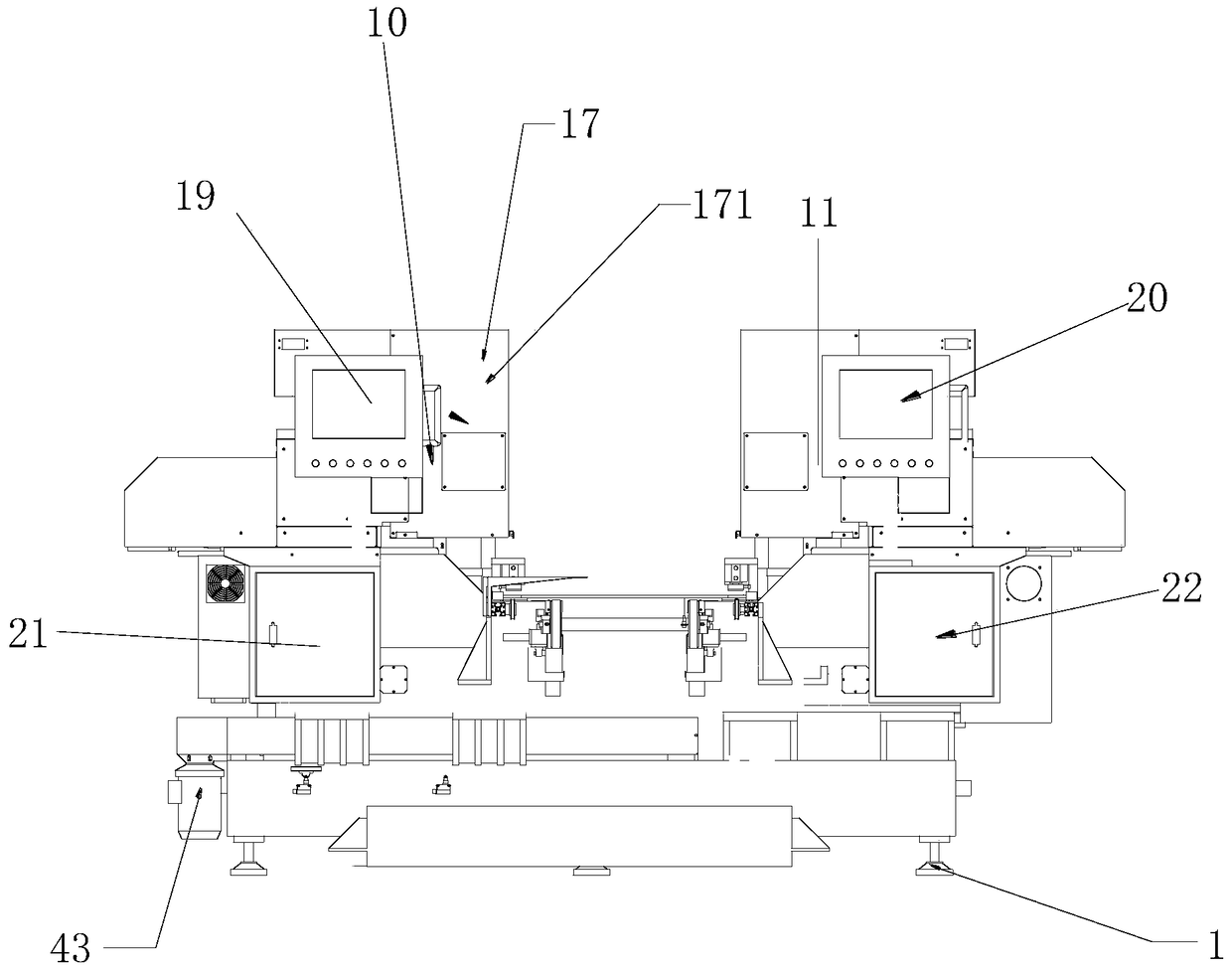

Precise grinding machine for processing solar energy prism

InactiveCN102259290BRun smoothlyImprove machining accuracyEdge grinding machinesOptical surface grinding machinesGrindingProcessing accuracy

The invention discloses solar energy prism processing equipment, and provides a precise grinding machine for processing a solar energy prism, which has the advantages of high automation degree and high processing precision, and is time-saving and labor-saving in clamping, and accurate in blank positioning. According to the precise grinding machine, the technical problems of time and labor waste, low positioning precision, poor processing quality, low possibility of satisfying use requirements when the solar energy prism is processed in the prior art can be solved. The precise grinding machinecomprises a processing platform, a grinding plate and a mechanical arm, wherein the grinding plate and the mechanism arm are arranged on the processing platform; the mechanical arm is connected with the blank by a grinding head spindle; the grinding head spindle is tubular; a sleeve is embedded in an axle hole on the front end of the grinding head spindle; the sleeve is provided with a draw bar capable of axially sliding along the sleeve; the front end key of the draw bar is connected with a leaning body bar; the leaning body bar is clamped and fixed in the sleeve by an elastic chuck; and therear end of the draw bar abuts against a power device by a belleville spring.

Owner:浙江博联智能科技有限公司

Digital tracking method of synchronous phase angle

InactiveCN100583641CEasy to handleEliminate precision errorsPulse automatic controlFrequency measurementsEngineering

This invention relates to simultaneous phase angle digital tracing method in the relative technique field and is characterized by the following: first inputting the simultaneous signals into radio measurement circuit to get the frequency division of outer crystal clock of CI and plug parameters of CR; then using the CI, CR as frequency division values input to the plug and division circuit.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com