Floating and breakage preventing screw tap clamp

A tap and fixture technology, which is applied in the field of floating anti-break tap fixtures, can solve problems such as twisting and broken taps, and achieve the effects of eliminating errors of different axes, reducing processing costs, and improving thread processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Now, the present invention will be described in detail in conjunction with the embodiments shown in the accompanying drawings.

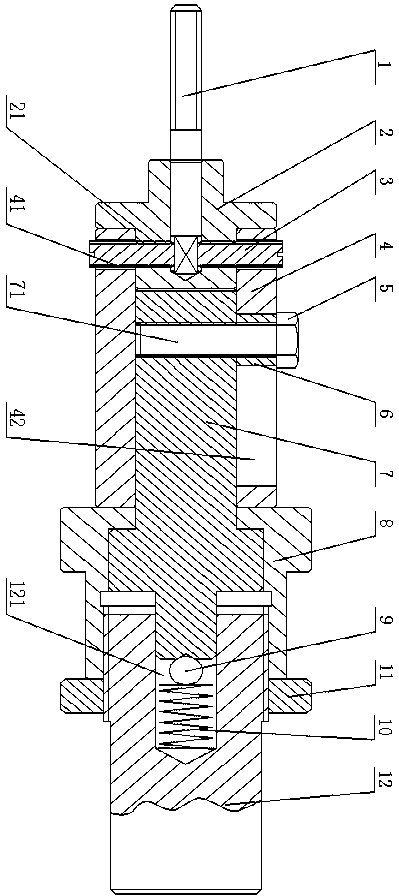

[0012] Such as figure 1 As shown, a floating anti-broken tap fixture: it includes a tap jacket 2, upper and lower slotted set screws 3, guide sleeve 4, anti-rotation bolt 5, mandrel 7, outer hexagon nut 8, torque transmission steel ball 9. Torque transmission spring 10, interlock nut 11, clamp handle 12, the inner hole of one end of the tap jacket 2 is in clearance fit with the tap 1, the outer circle of the other end is excessively fitted with the inner hole of the guide sleeve 4, the tap jacket 2 A threaded hole 21 is provided on the outer circle of one end that is excessively matched with the inner hole of the guide sleeve 4, and a through hole 41 is provided on the opposite side of the outer circle of one end of the guide sleeve 4. The central axis of the threaded hole 21 coincides, and the upper and lower slotted set screws 3 pass throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com