Bilateral connection intelligent chamfering machine

A chamfering machine and connection technology, which is applied in the direction of machine tools suitable for grinding workpiece edges, grinding racks, and parts of grinding machine tools, can solve the problems of insufficient processing efficiency, rising labor costs, and low intelligence and other problems, to achieve the effects of small distortion, improved production efficiency and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

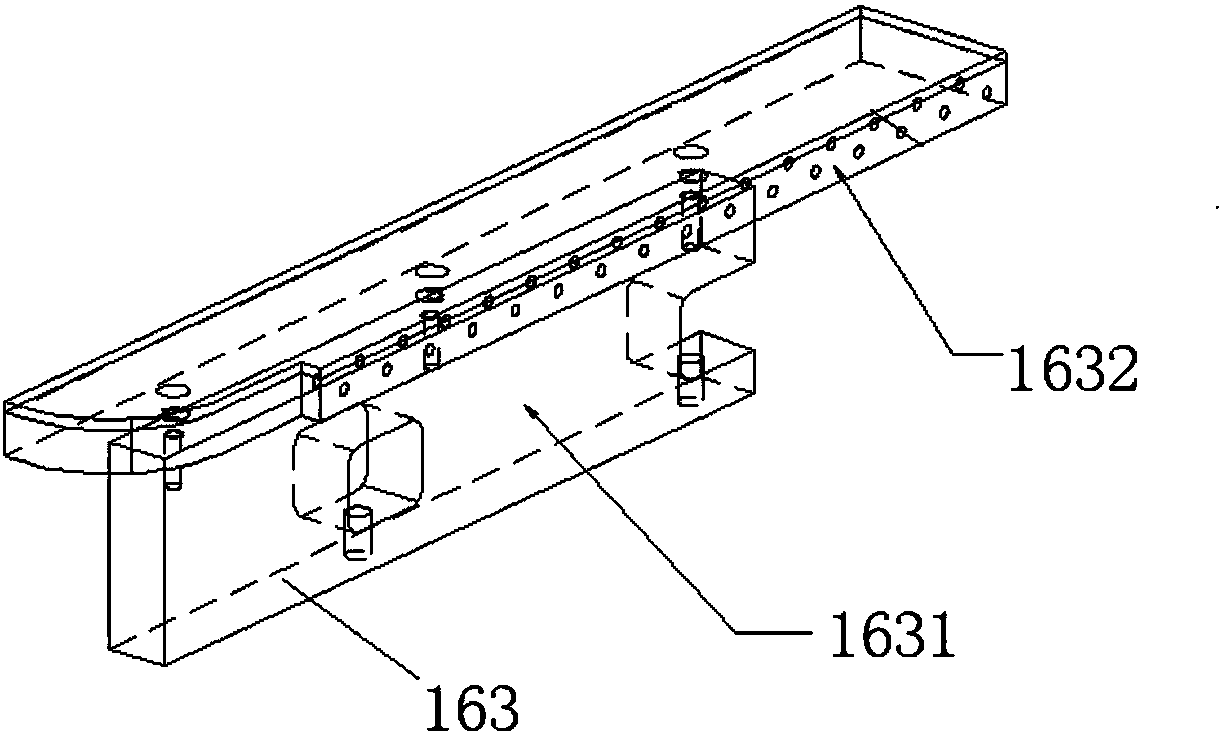

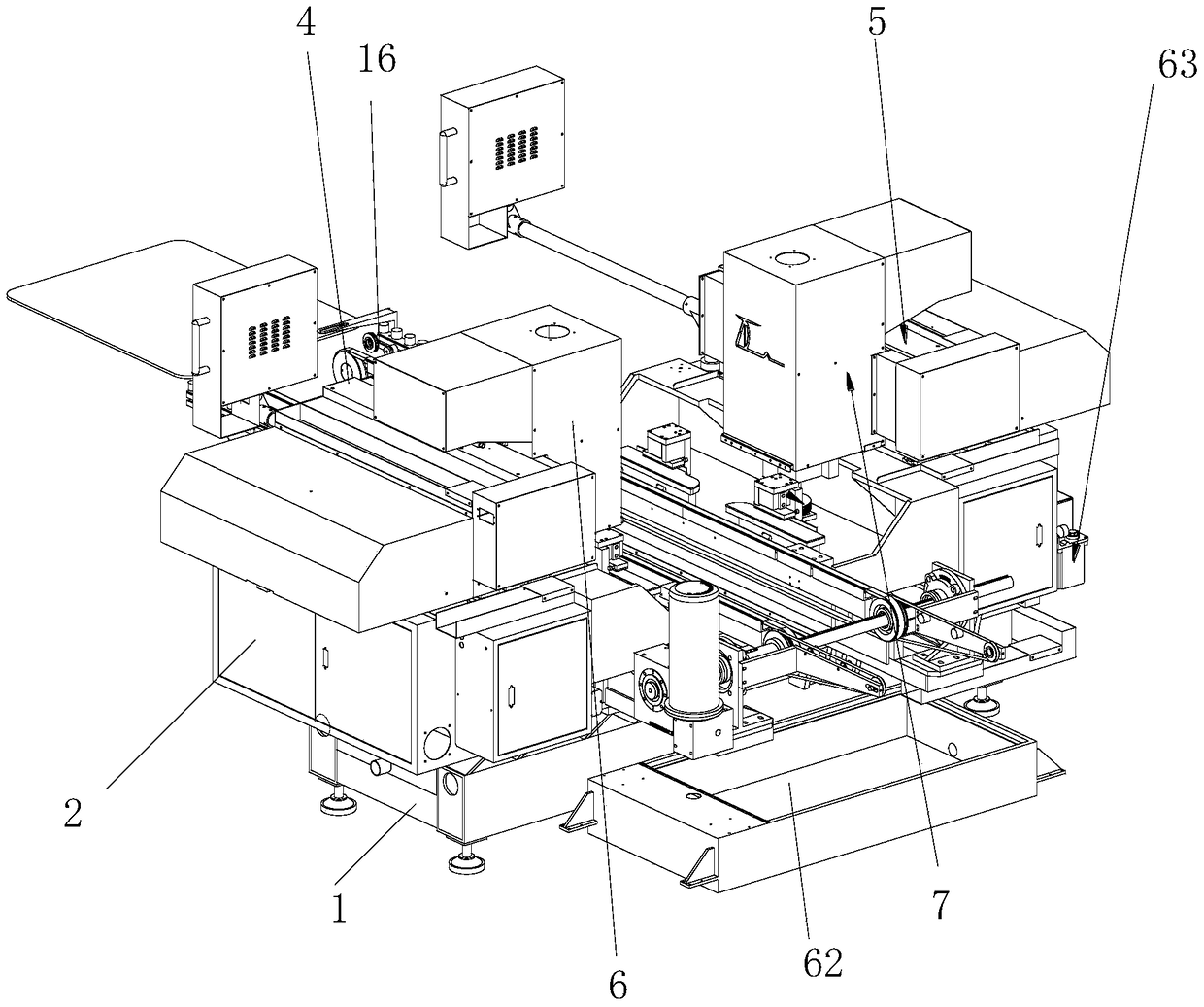

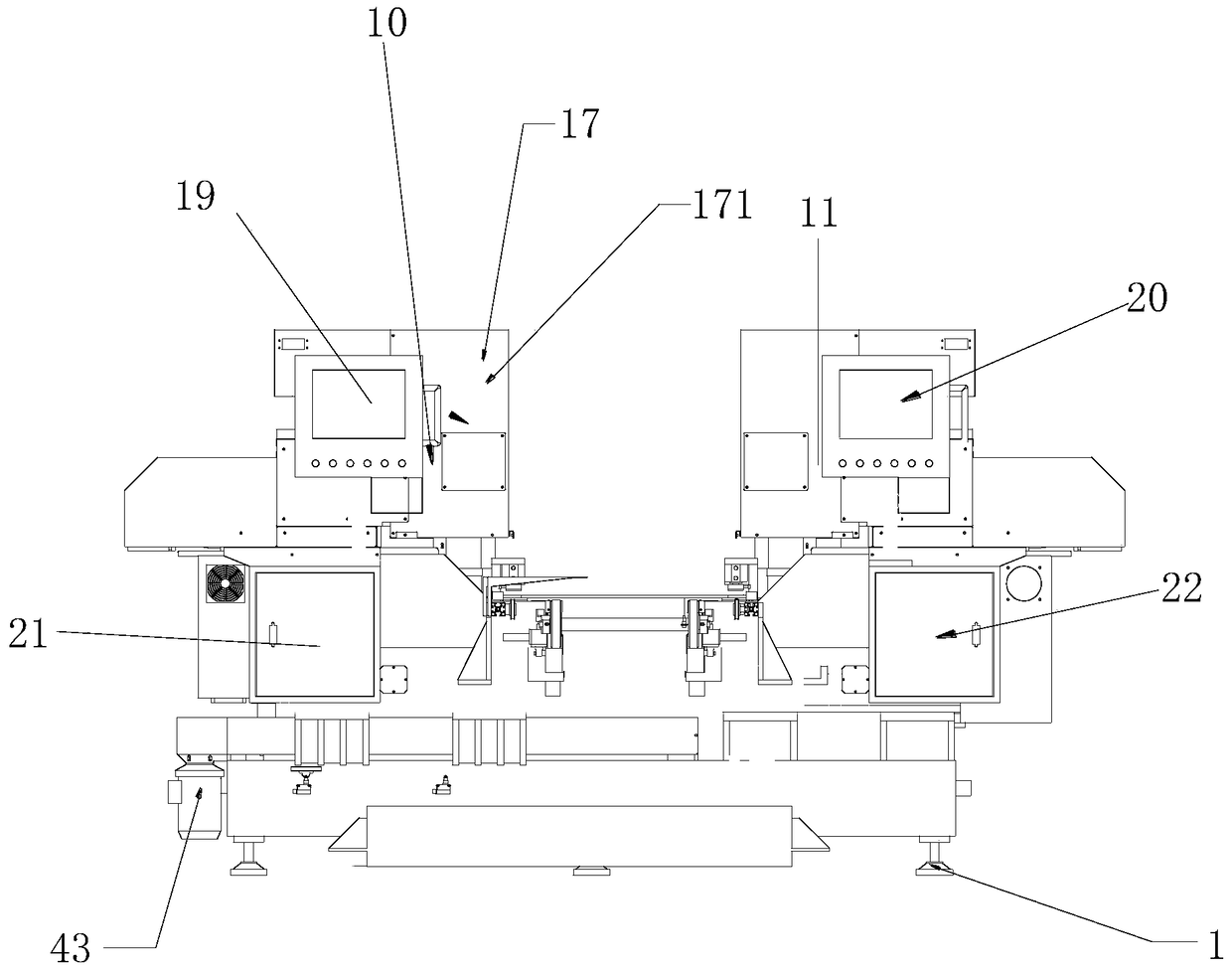

[0044] as attached Figure 1-13 The double-sided connection intelligent chamfering machine includes a main frame base 1, on which a main frame 2 and a secondary frame 3 are arranged, the main frame 2 and the secondary frame 3 are arranged oppositely, and the beam 4 and 5 slide along the Y-axis direction on the main frame 2 and the slave frame 3 respectively, X-axis sliding tables 6 and 7 are arranged on the crossbeams 4 and 5, and two spindle motors are respectively installed on the Z-axis On the slide tables 10 and 11, the Z-axis slide tables 10 and 11 are installed on the X-axis slide tables 6 and 7, the spindle motors 12 and 13 are equipped with grinding mechanisms 14 and 15, and the main frame The base 1 is provided with a glass conveying and pressing mechanism 16, and the glass conveying and pressing mechanism 16 includes an initial positioning mechanism 161, a front synchronous wheel up and down movable mechanism 162, a glass fixture 163, a glass pressing mechanism 164 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com