Accurate magnetic suspension worktable for photo etching under extra ultraviolet

A technology of extreme ultraviolet lithography and magnetic levitation, which is applied in the direction of microlithography exposure equipment, electrical components, semiconductor/solid-state device manufacturing, etc. It can solve problems such as vibration shock and wire tension, achieve stable movement, eliminate precision errors, and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with specific embodiments.

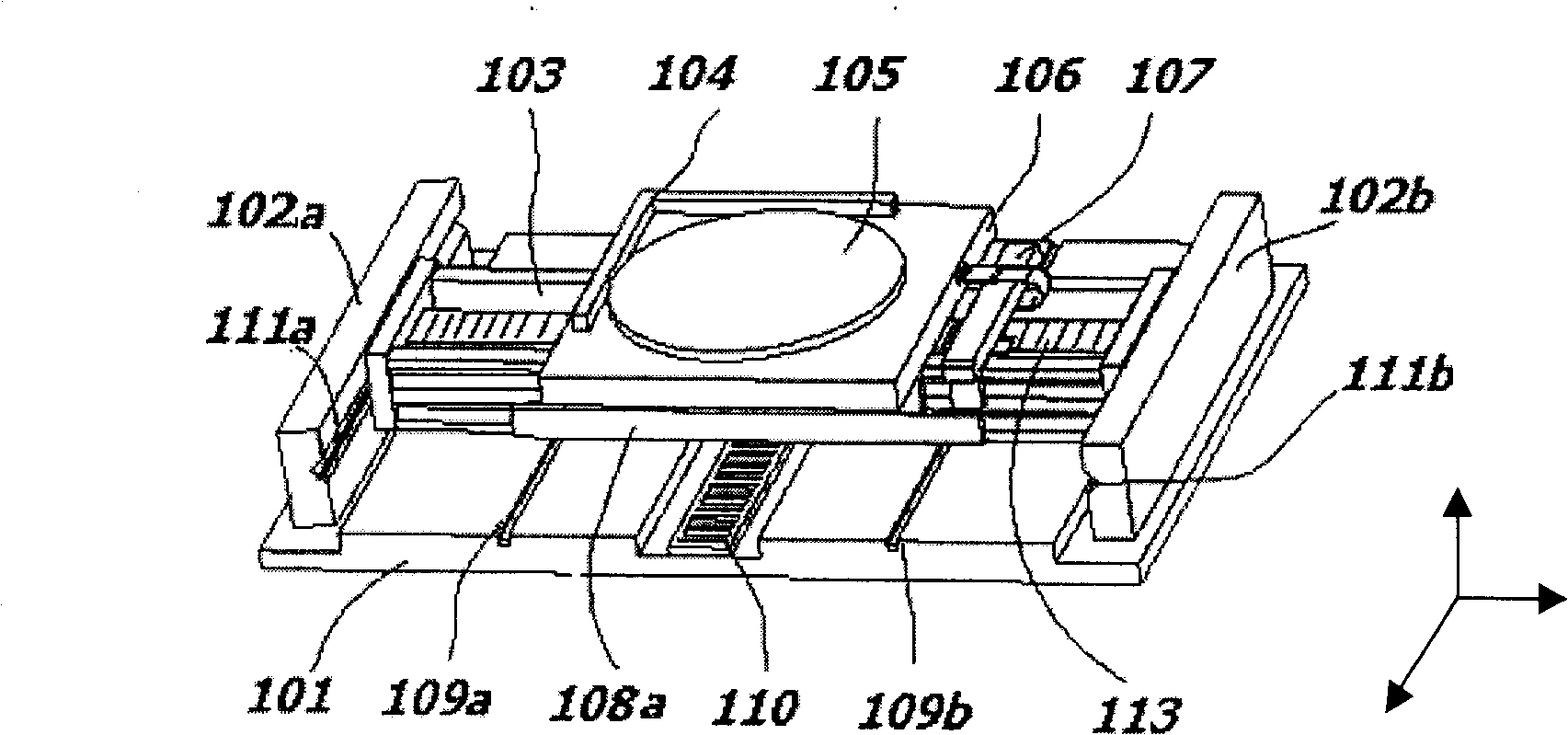

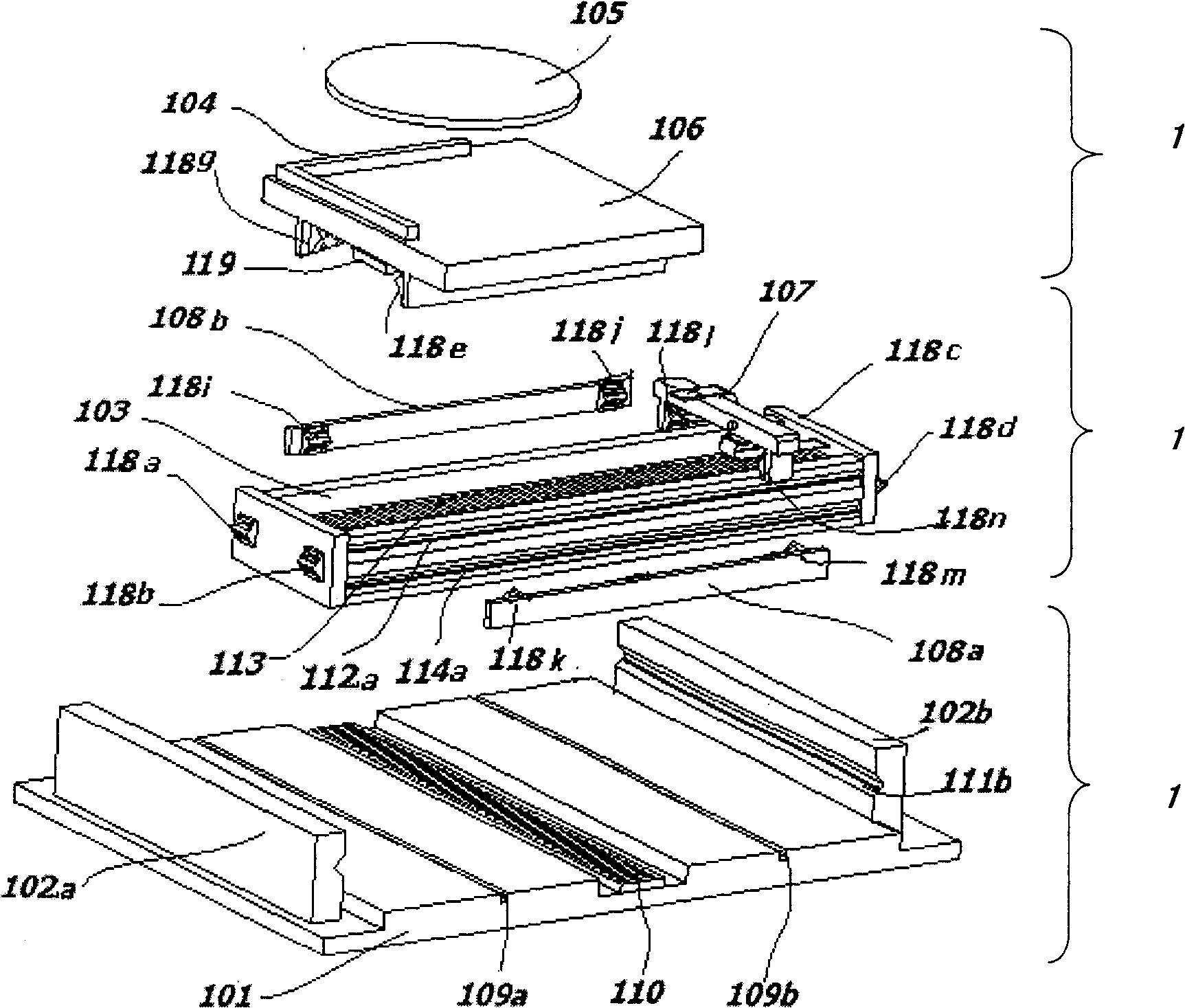

[0053] figure 2 , image 3 It is the overall structural arrangement of the present invention. Such as image 3 As shown, the present invention includes three parts: a micro-positioning platform assembly 117 , a coarse positioning platform assembly 125 and a base assembly 132 . The main body of the base assembly 132 is composed of the base 101 and two Y-direction maglev guide rails 102a, 102b fixed at both ends of the base. A Y-direction linear motor primary 110 and two magnetic strips 109a, 109b are mounted on the upper surface of the base 101 . The main body of the coarse positioning platform assembly 125 includes the walking beam 103 , the cable table 107 and the counterweight 108 . The coarse positioning stage assembly 125 is supported by the base assembly 132 through the magnetic levitation guide rail 102 . A Y-direction linear motor secondary 116 and two magnets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com