Spur gear numerical control machining method

A processing method and technology of spur gears, which are applied in the field of mechanical processing, can solve problems such as tooth shape and inner hole precision error amplification, and achieve the effect of eliminating precision errors and ensuring machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

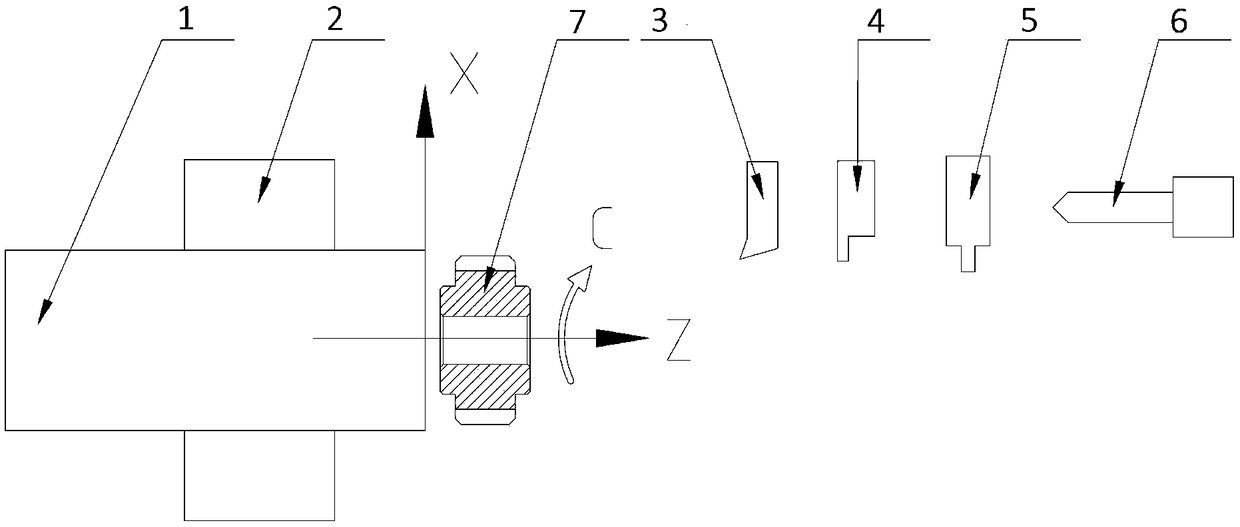

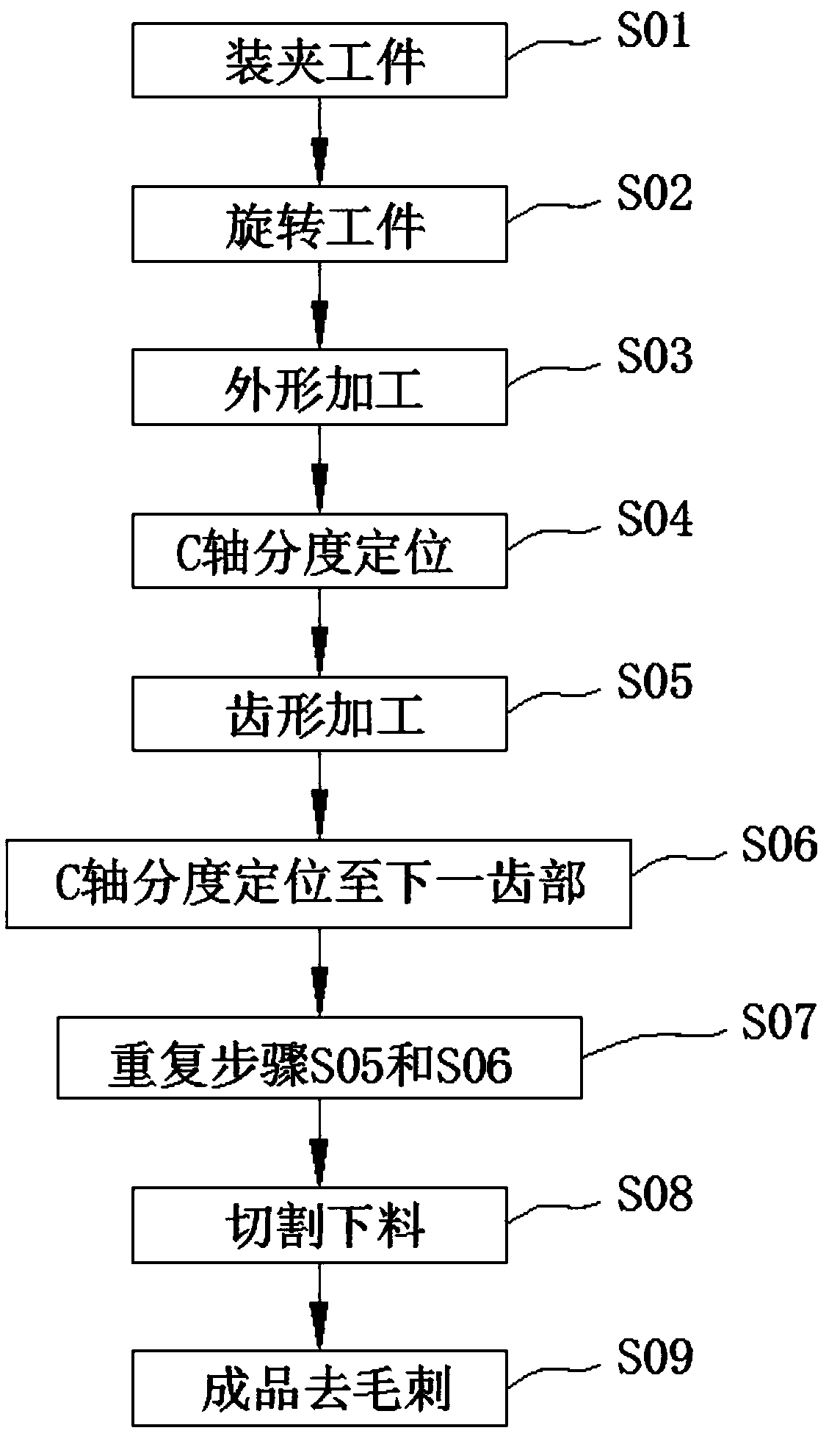

[0023] refer to figure 1 and figure 2 , the present invention provides a spur gear numerical control machining method, comprising the following steps: step S01, clamping a workpiece; clamping a bar blank 1 through a clamping device 2 of a CNC machine tool; step S02, rotating the workpiece; clamping device 2 Drive the bar blank 1 to rotate; step S03, shape processing; process the shape of the spur gear through the shape tool 3, cutting tool 4, and inner hole tool 6 of the CNC machine tool, and do not cut off the gear blank. 4 and the inner hole tool 6 to process the outline of the semi-finished gear workpiece 7; Step S04, C-axis indexing and positioning; through the C-axis function of the numerical control system, the indexing and positioning is performed, so that the bar blank 1 with the shape of the spur gear has been processed Accurately stop at the starting position of the first tooth; step S05, tooth profile processing; use the tooth profile cutter 5, and process the too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com