A measuring scale, its manufacturing method and using method

A technology for measuring rulers and markings, which is applied in the direction of instruments, nonlinear optics, optics, etc. It can solve the problems of electric field distribution changes, lack of high-precision detection equipment, and graphic interference, so as to eliminate measurement equipment errors and facilitate abnormal tracking. The effect of eliminating precision errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

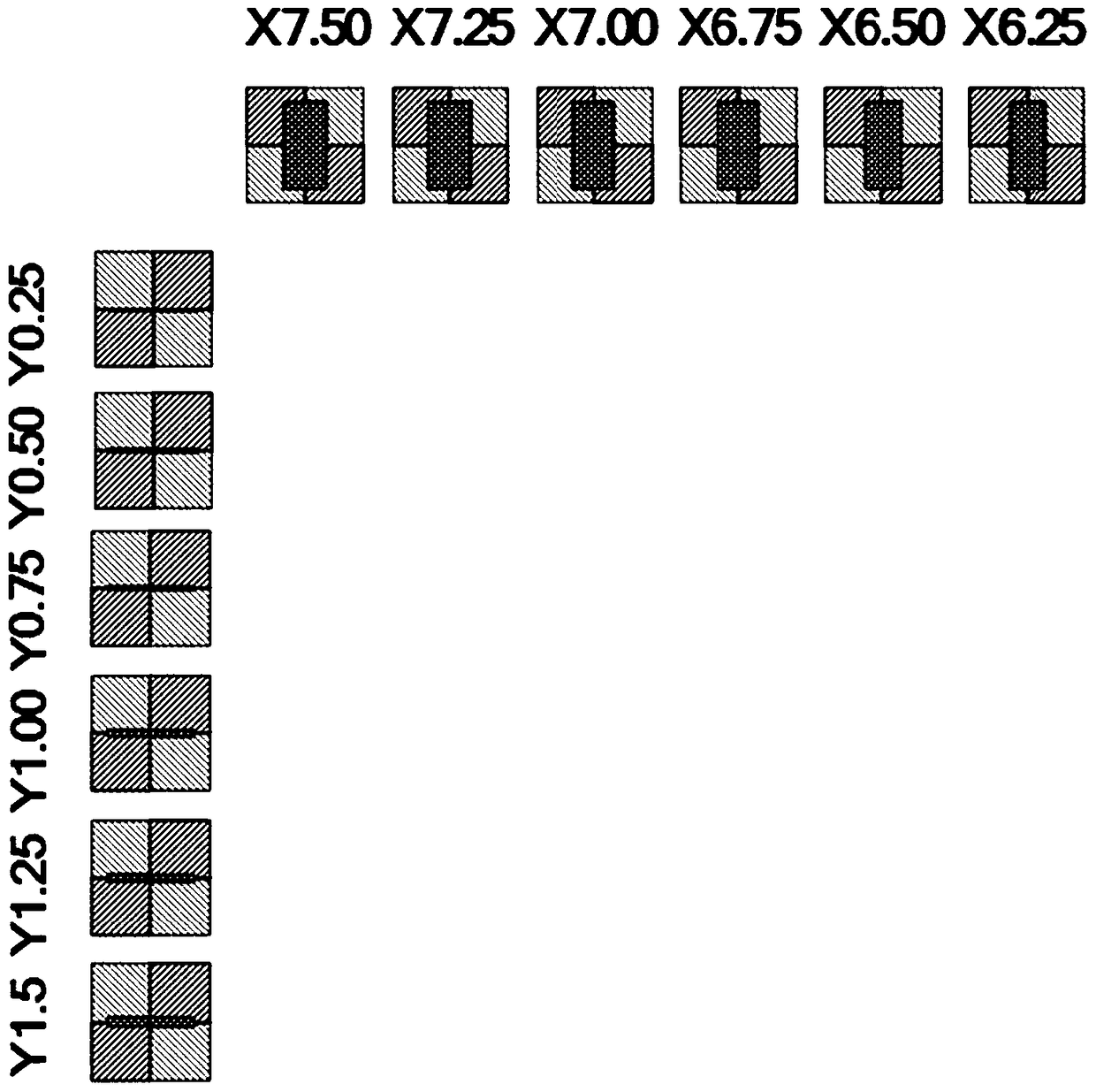

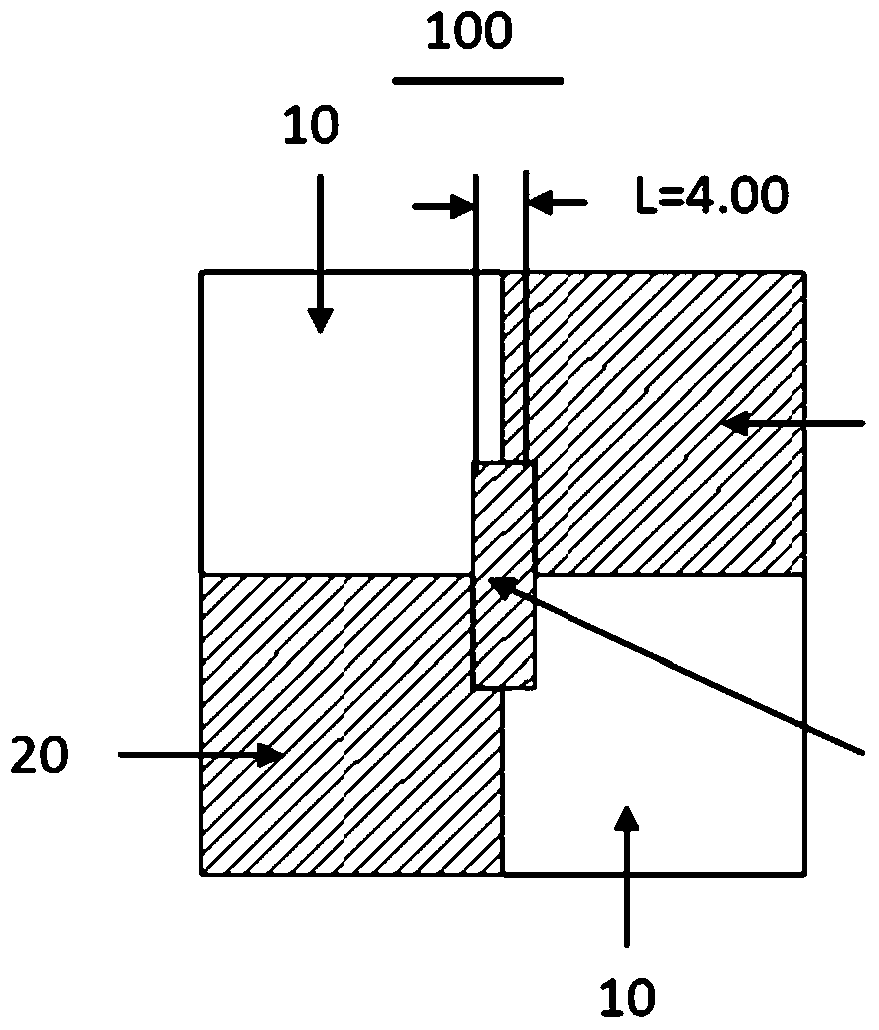

[0031] As shown in Figure 1(a) and Figure 1(b), according to the manufacturing process of the array substrate or color filter substrate, the present invention sets a measuring scale outside the pixel area of the array substrate or color filter substrate, and the measuring scale is used to measure the The line width (CD) unilateral etching amount of each layer material of the substrate or the color filter substrate and the offset value of the overlay accuracy (Overlay) between each layer material, the line width (CD) can be directly read visually through the measurement scale The amount of unilateral etching and the offset value of the overlay accuracy (Overlay) between the materials of each layer can achieve the purpose of visual inspection.

[0032] Wherein, the array substrate also includes an LTPS (low temperature polysilicon technology) substrate, an IGZO (metal oxide) substrate, and an OLED substrate.

[0033] The measuring scale includes an X-direction measuring scale ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com