Precise grinding machine for processing solar energy prism

A precision grinding machine and solar energy technology, which is applied in the direction of machine tools, grinding machines, metal processing equipment, etc., which are suitable for grinding the edge of workpieces, can solve problems such as difficult to meet the use requirements, low positioning accuracy, poor processing quality, etc., and achieve clamping process Time-saving and labor-saving, high production efficiency and good versatility

Inactive Publication Date: 2013-05-01

浙江博联智能科技有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The present invention mainly provides a precision grinding machine for processing solar prisms with high degree of automation, time-saving and labor-saving clamping, accurate blank positioning, and high processing precision, which solves the time-consuming and labor-intensive processing of solar prisms in the prior art. , low positioning accuracy, poor processing quality, difficult to meet technical problems such as use requirements

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0027] The specific embodiments described herein are merely illustrative of the concepts of the present invention. Those skilled in the art to which the present invention belongs can make various modifications or supplements to the described specific embodiments or adopt similar methods to replace them, but they will not deviate from the spirit of the present invention or go beyond the definition of the appended claims range.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

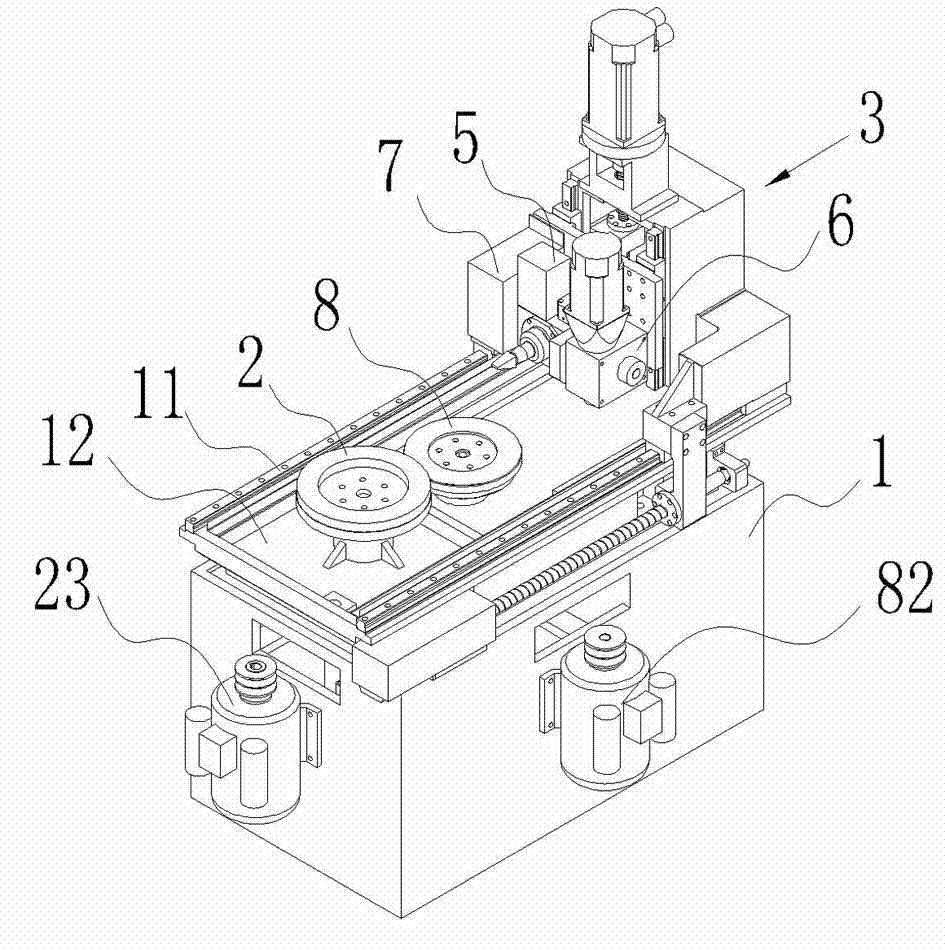

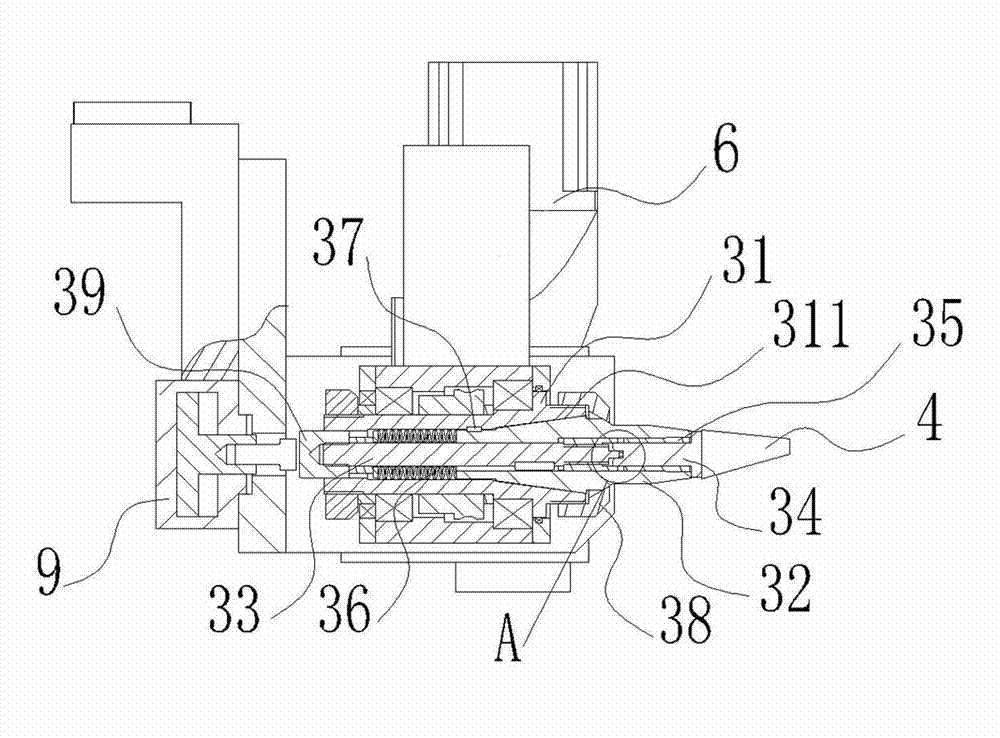

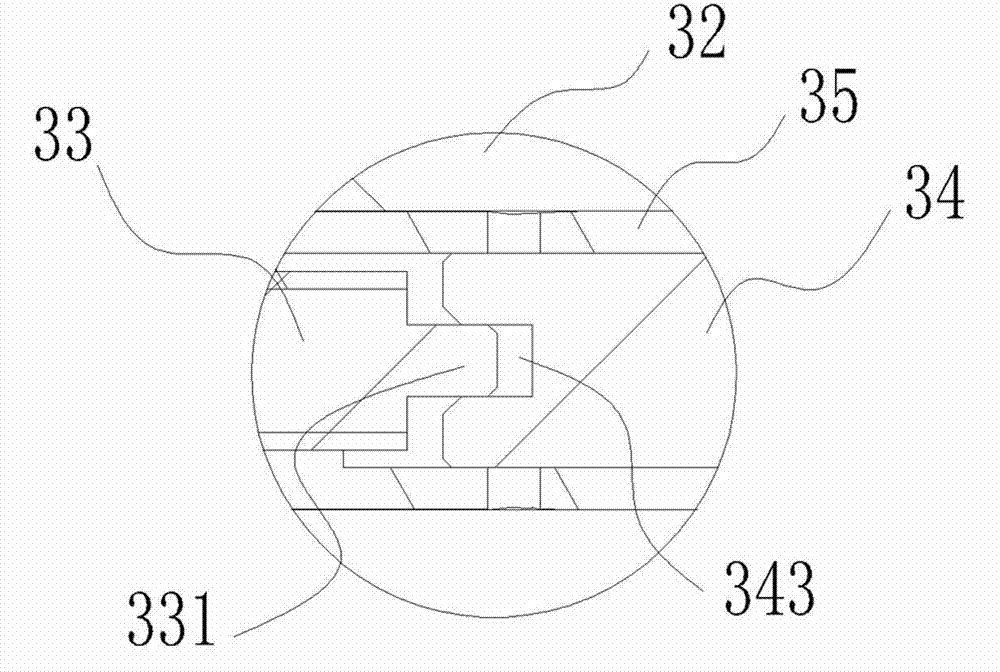

The invention discloses solar energy prism processing equipment, and provides a precise grinding machine for processing a solar energy prism, which has the advantages of high automation degree and high processing precision, and is time-saving and labor-saving in clamping, and accurate in blank positioning. According to the precise grinding machine, the technical problems of time and labor waste, low positioning precision, poor processing quality, low possibility of satisfying use requirements when the solar energy prism is processed in the prior art can be solved. The precise grinding machinecomprises a processing platform, a grinding plate and a mechanical arm, wherein the grinding plate and the mechanism arm are arranged on the processing platform; the mechanical arm is connected with the blank by a grinding head spindle; the grinding head spindle is tubular; a sleeve is embedded in an axle hole on the front end of the grinding head spindle; the sleeve is provided with a draw bar capable of axially sliding along the sleeve; the front end key of the draw bar is connected with a leaning body bar; the leaning body bar is clamped and fixed in the sleeve by an elastic chuck; and therear end of the draw bar abuts against a power device by a belleville spring.

Description

technical field [0001] The invention relates to solar prism processing equipment, in particular to a precision grinding machine for processing solar prisms with precise blank material positioning and high processing precision. Background technique [0002] Solar prisms are important components in solar cells. The surface accuracy of solar prisms directly affects the performance of solar cells. Early solar prisms are generally ground by hand, which not only has low production efficiency, but also often makes it difficult to guarantee the surface quality. Existing solar prisms The processing is generally to fix the blank on the mechanical arm, and then adjust the position of the blank through the mechanical arm, so that it can be in contact with the grinding disc to achieve the purpose of grinding, but the blank is very easy to produce radial or circumferential edges during processing. The shaking of the direction directly leads to the low processing precision and poor quality...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B24B13/00B24B13/005B24B9/14

Inventor 黄永生

Owner 浙江博联智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com