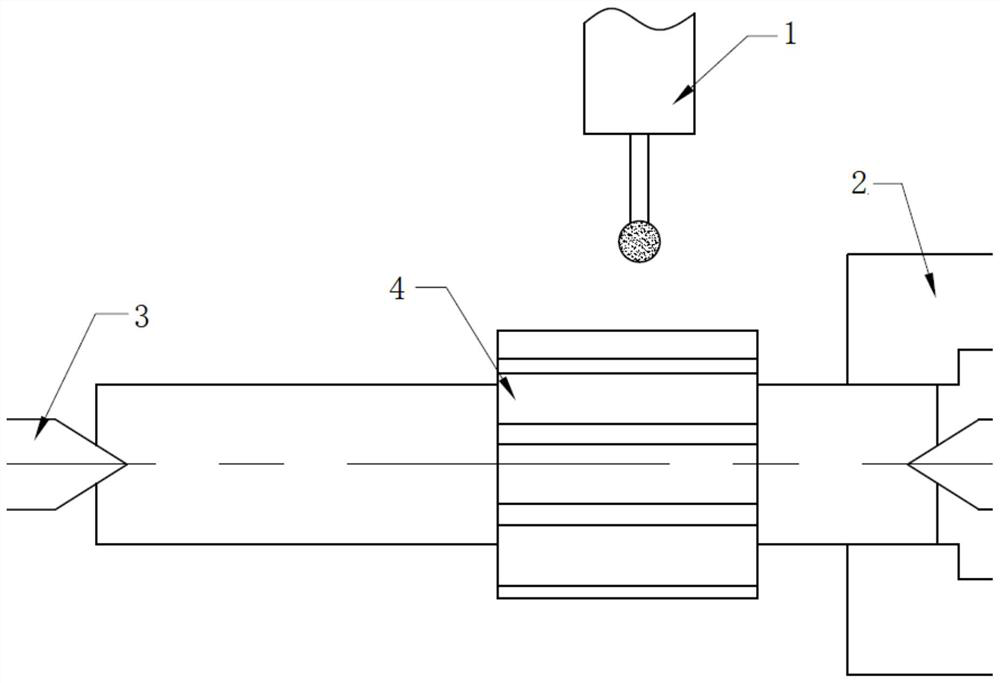

Tooth profile positioning method and tooth profile positioning control system

A positioning method and positioning control technology, applied in the direction of gear teeth, toothed components, belts/chains/gears, etc., can solve problems such as the inability to quickly and effectively realize precise tooth profile positioning, and improve the flexibility of machining processes , shorten the positioning time of the tooth profile, and improve the positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

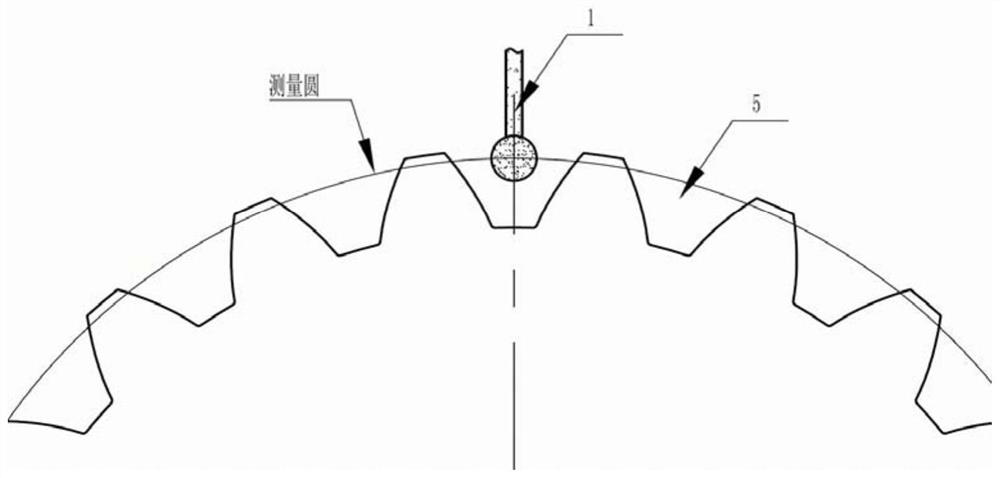

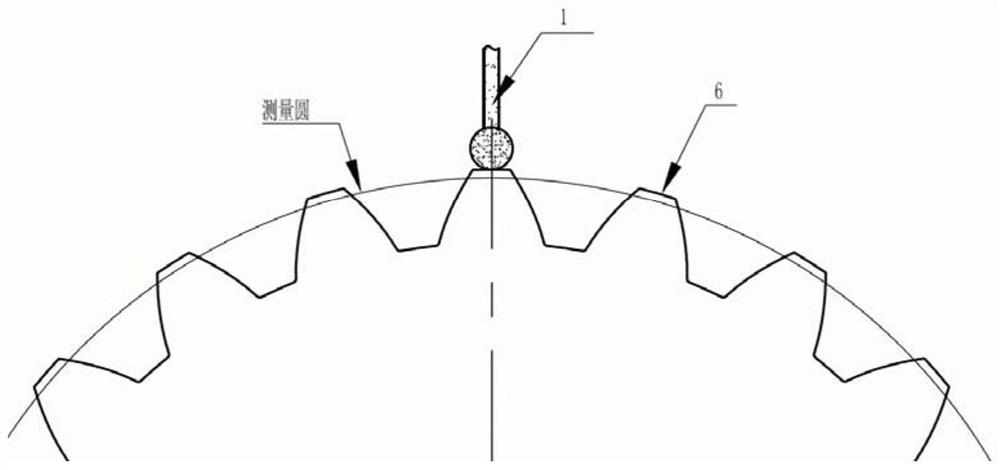

[0065] In this embodiment, a certain axis is taken as an example, and the tooth shape positioning is carried out in a four-axis machining center. The tooth shape of this axis is characterized by a small tooth thickness on both sides and a large middle tooth thickness. , it cannot be finished by conventional methods such as gear shaping, hard hobbing, shaving, grinding, etc., so the final solution is to use a small hob (to avoid interfering with the transition part of the tooth thickness) for rough machining, and then Finishing is done on a machining center with a form milling cutter. Precise gear positioning is required before forming milling cutters for finishing. The tooth profile parameters after rough machining are shown in Table 1:

[0066] Table 1. Known tooth shape parameters after hobbing

[0067] name value Number of teeth Z 22 Modulus m 3 pressure angle α 30° Addendum circle diameter df 69.4 Root garden diameter db 60.7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com