Cargo ship independent cargo tank mounting method

An installation method and cargo ship technology, applied to ship parts, ship construction, ship design, etc., can solve the problems of overall construction efficiency and low construction precision of asphalt ships, reduce manual processing workload, improve construction environment, and improve final precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

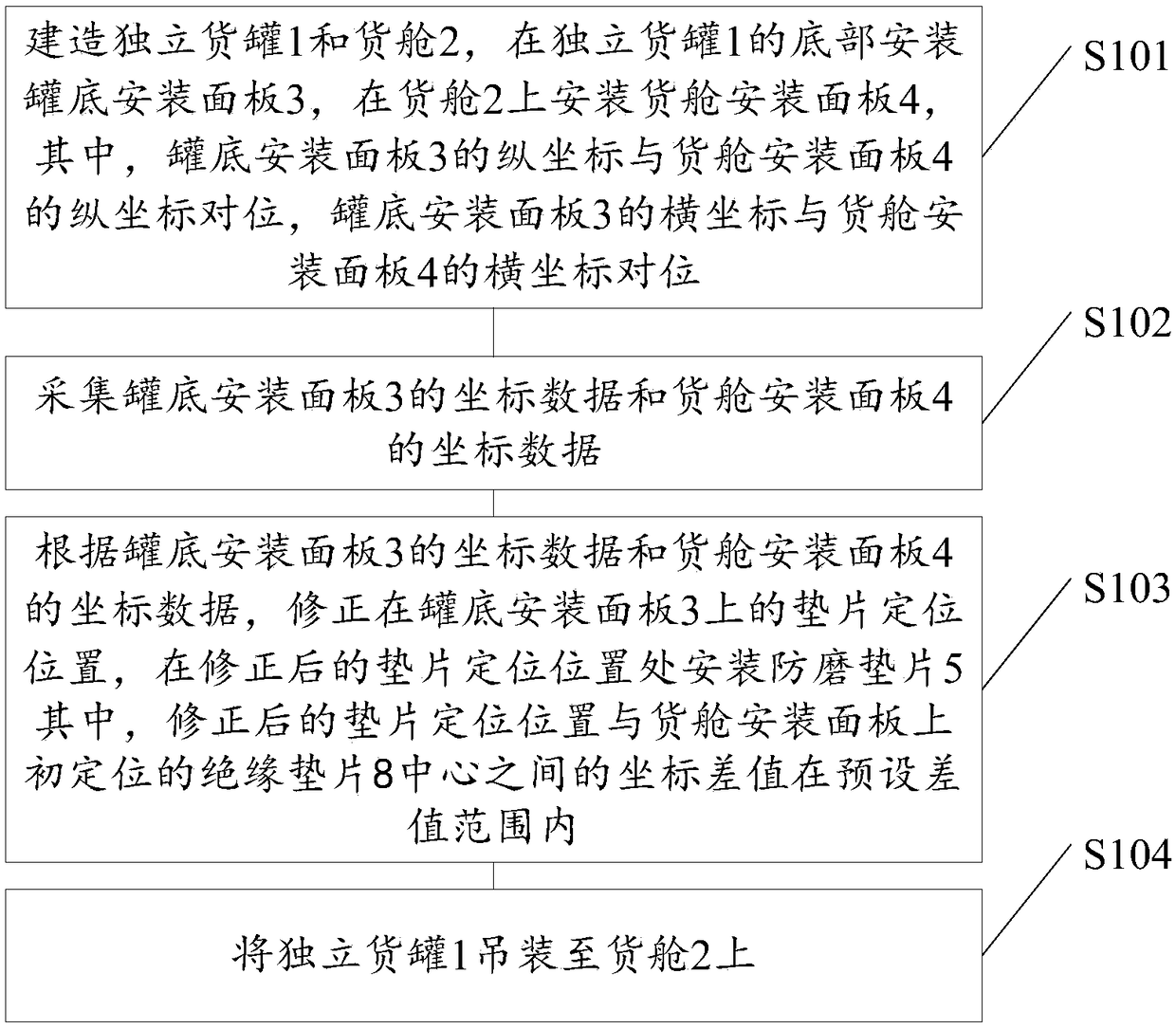

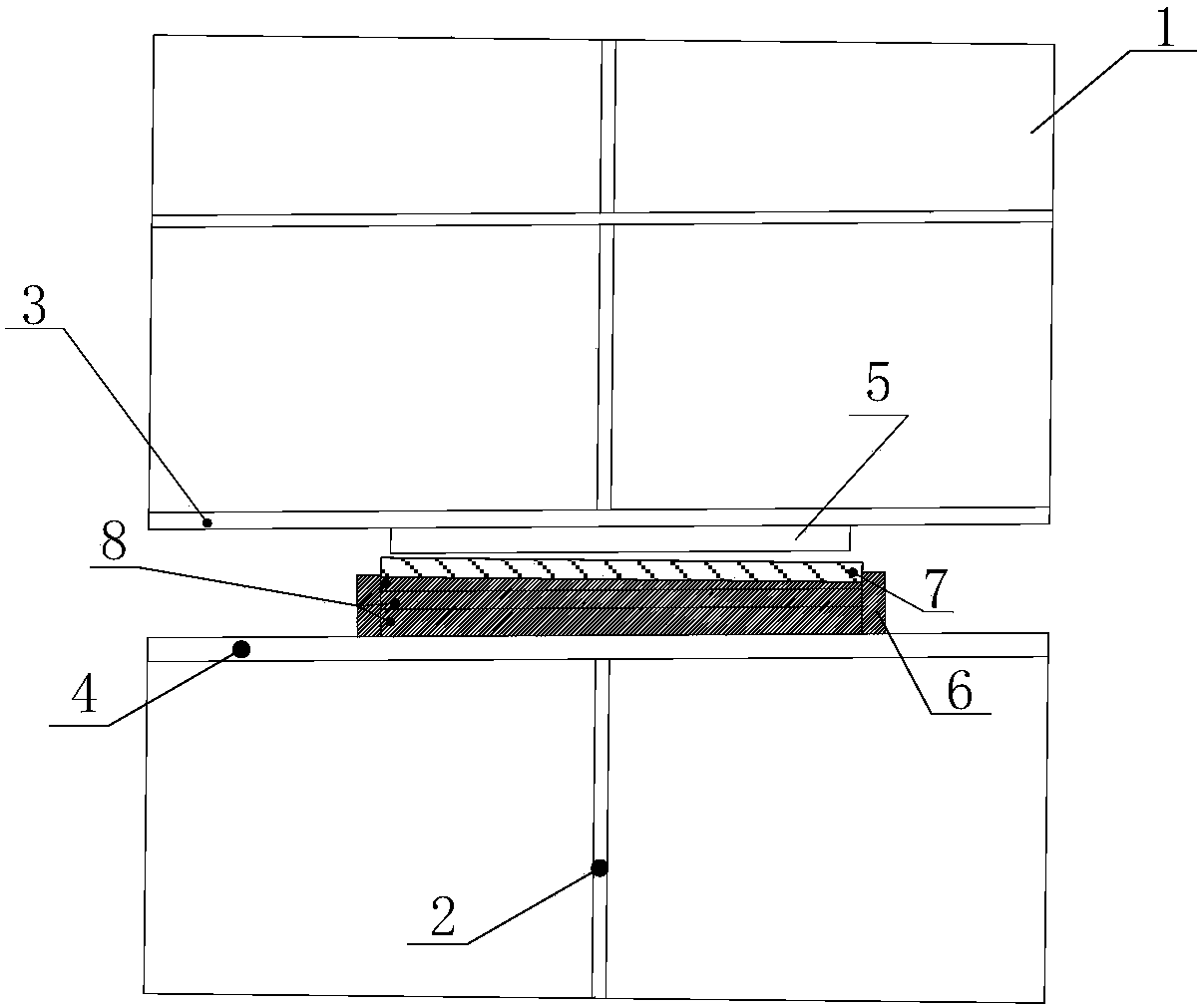

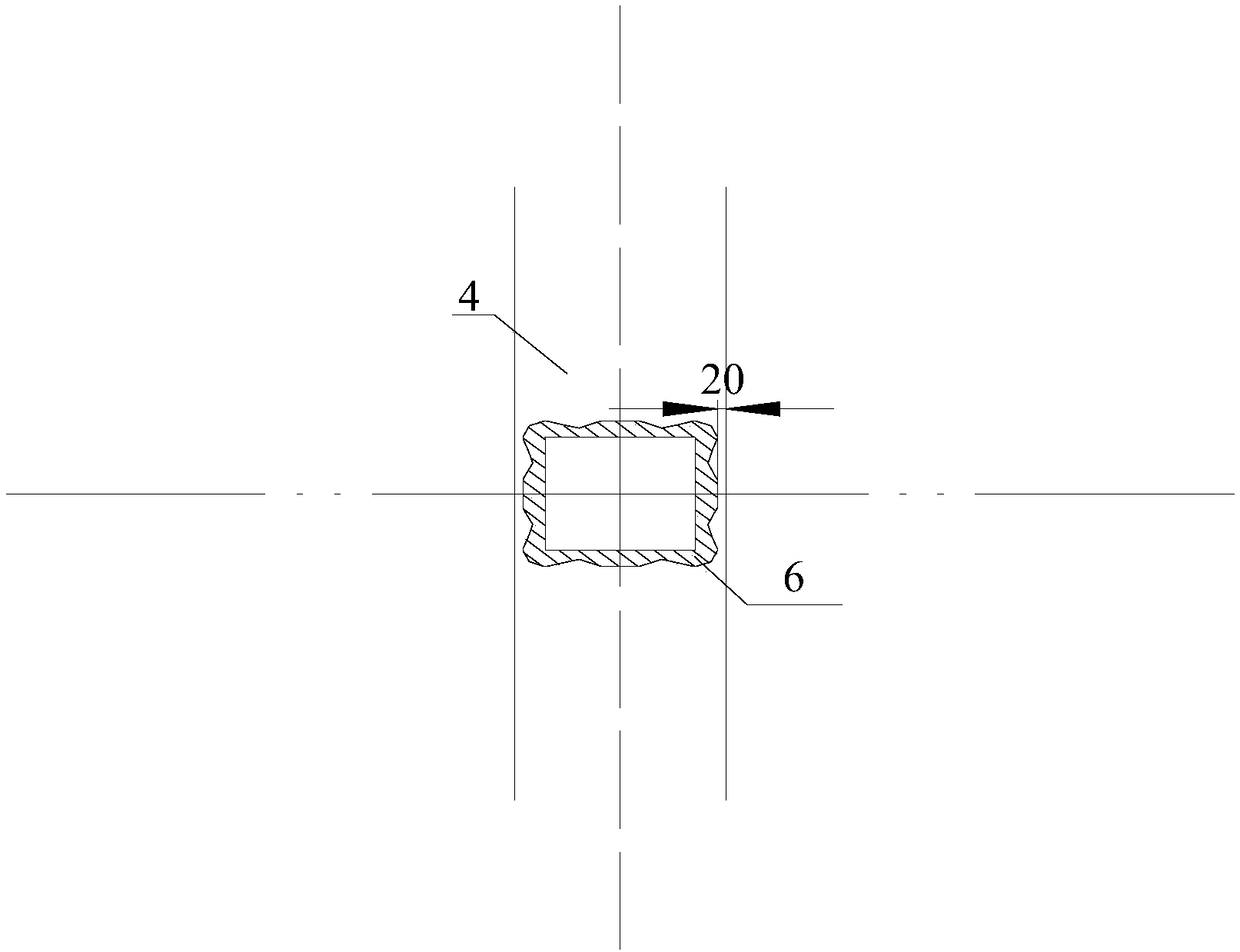

[0048] In order to solve the technical problems of overall construction efficiency and low construction precision of asphalt ships, the embodiment of the present invention provides a method for installing independent cargo tanks of cargo ships. The general idea is as follows:

[0049] Build independent cargo tanks and cargo holds, install tank bottom installation panels at the bottom of independent cargo tanks, install cargo hold installation panels on the cargo hold, align the vertical coordinates of the tank bottom installation panels with those of the cargo hold installation panels, and The coordinates are aligned with the abscissa coordinates of the cargo compartment installation panel; the coordinate data of the tank bottom installation panel and the coordinate data of the cargo compartment installation panel are collected; according to the coordinate data of the tank bottom installation panel and the coordinate data of the cargo compartment installation panel, correction i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com