Atomic gas chamber surface stress test device and test method

An atomic gas chamber and surface stress technology, which is applied in the direction of measuring the force of change of optical properties of materials when they are stressed, can solve the problem of low stress test accuracy of micro-small atomic gas chambers and complex structure of penumbra analyzer method. , high requirements for polarizing devices, to achieve the effect of convenient optical path alignment, compact structure and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below by means of the accompanying drawings and specific embodiments.

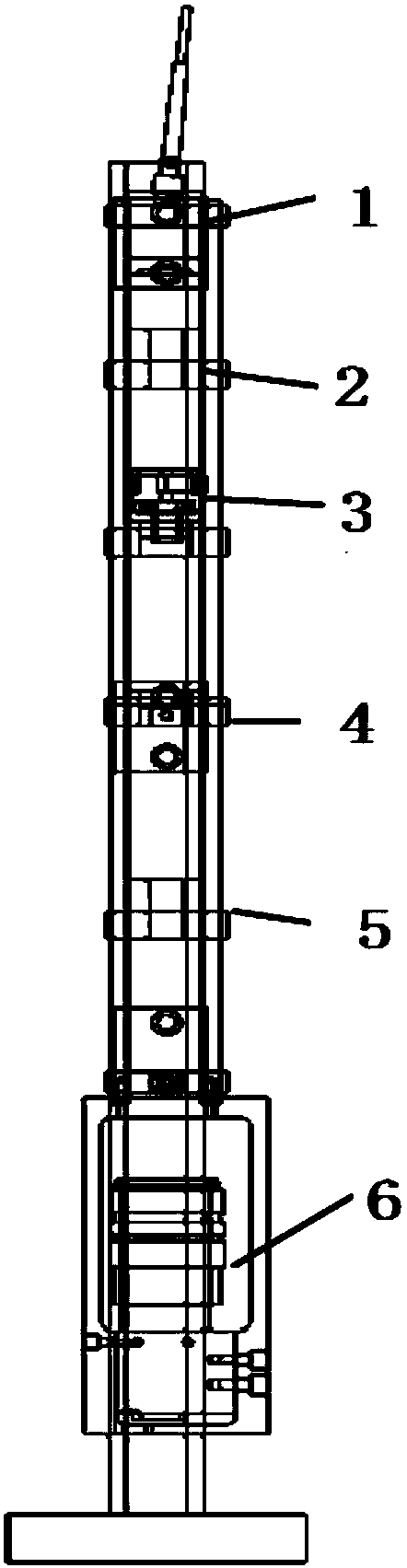

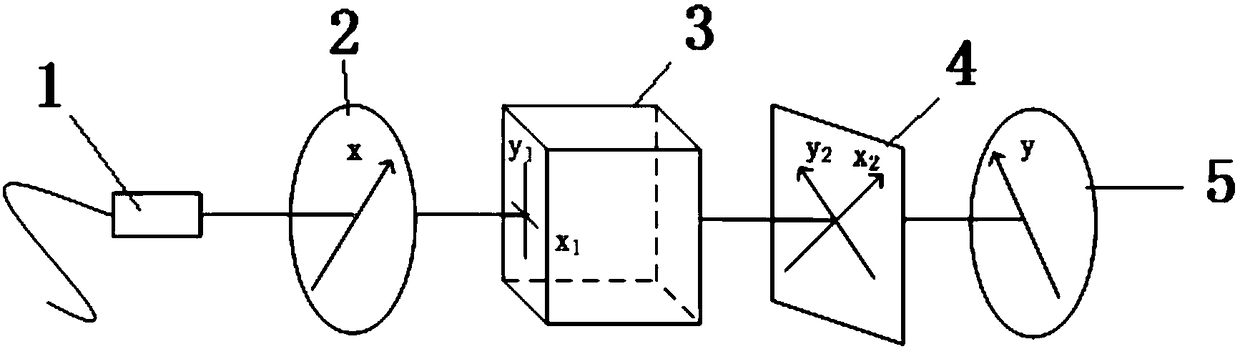

[0030] Such as figure 1 As shown, the atomic gas chamber surface stress testing device includes a laser collimator 1, a polarizer 2, an atomic gas chamber 3, a 1 / 4 wave plate 4, an analyzer 5, a CCD and a lens 6, which are respectively from top to bottom Install to form a cage structure, the cage structure includes the above six devices, four steel poles, fixed mounts and optical adjustment mounts, the above devices are passed through the fixed mounts and optical adjustment mounts along the common The optical axis is installed on the support rod.

[0031] The cage structure is convenient for optical path alignment, and the structure is simple and compact, stable and reliable

[0032] A method for testing surface stress based on an atomic gas chamber, the steps of which are as follows:

[0033] 1) Collimating the light source through a laser collimat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com