Wafer performance test sample application all-in-one machine

An all-in-one spotting and all-in-one technology, applied in the field of wafer performance testing spotting all-in-one machines, can solve the problems of low wafer processing efficiency and low precision, and achieve the effect of improving equipment efficiency, improving efficiency and quality, and eliminating the problem of precision errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

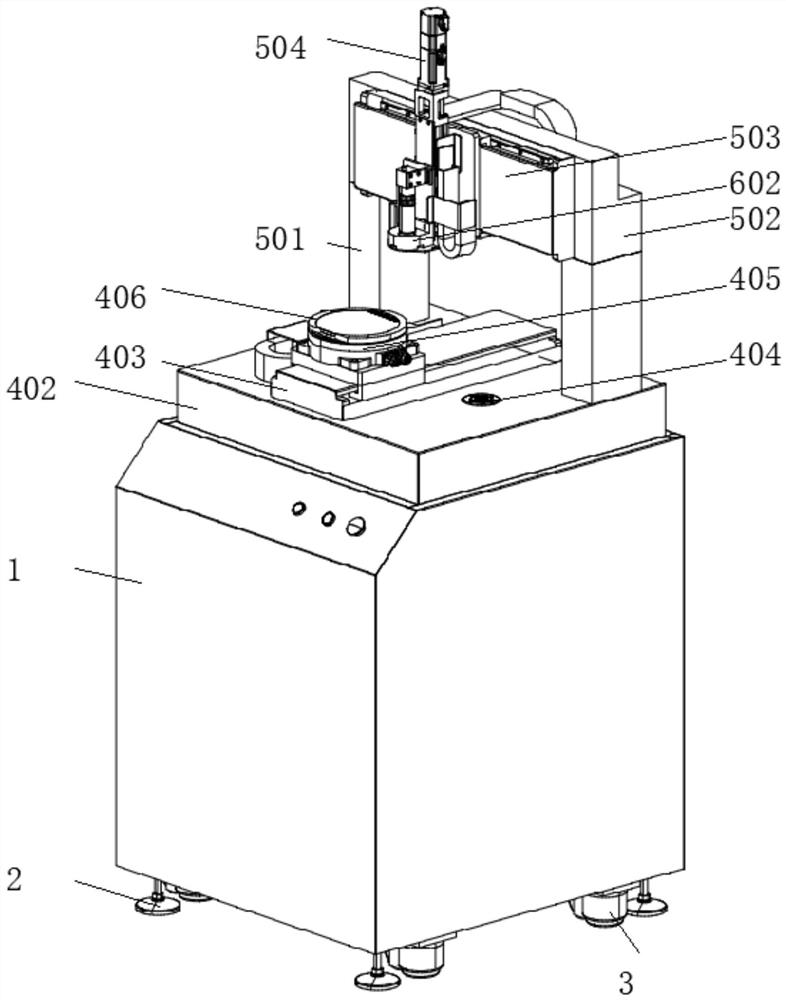

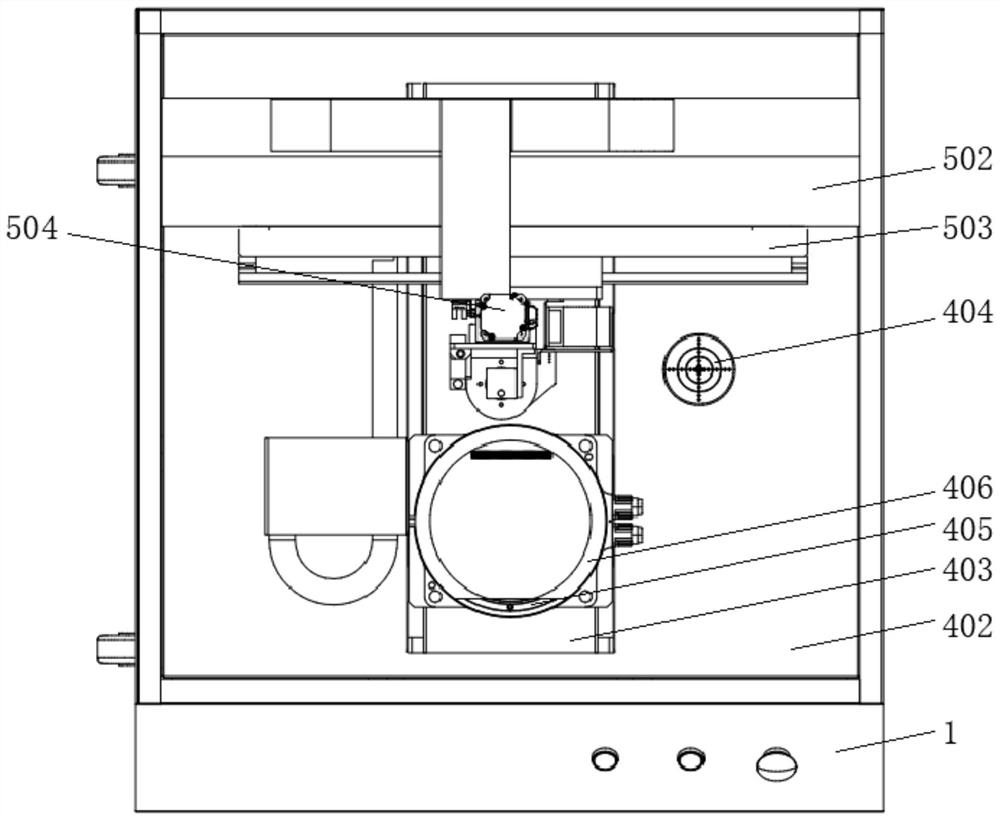

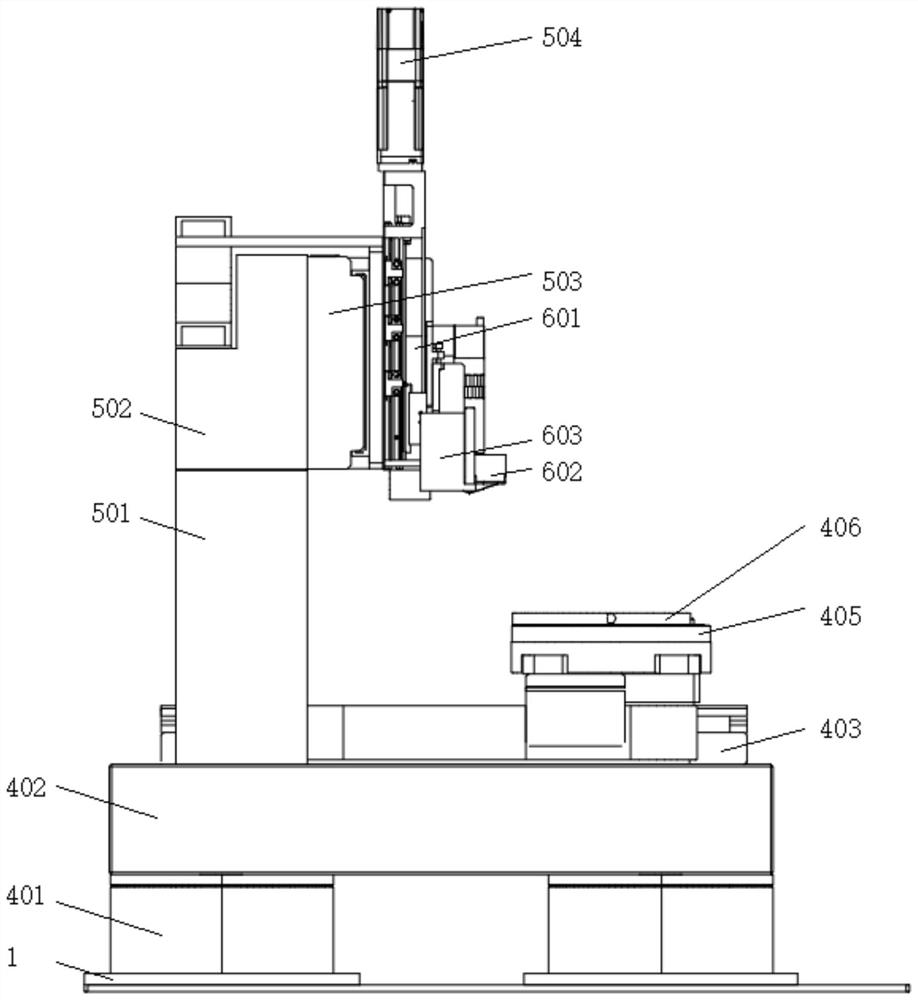

[0032] An all-in-one machine for wafer performance testing and sampling, including a system control cabinet 1, the bottom of which is symmetrically equipped with load-bearing leveling support feet 2 and universal Fuma wheel 3, and the top of the system control cabinet 1 is equipped with a wafer placement Mechanism, position adjustment mechanism and performance testing and sampling integration mechanism;

[0033] The wafer placement mechanism is arranged above the system control cabinet 1. The wafer placement mechanism is used to place the wafer when performing performance testing and spotting of the wafer. The wafer placement mechanism includes an air suspension shock absorber 401, a marble platform 402 and a Y The axis control assembly 403, the air suspension shock absorber 401 is fixed on the top of the system control cabinet 1, the marble platform 402 is arranged on the top of the air suspension shock absorber 401, and the Y axis control assembly 403 is arranged on the top o...

Embodiment 2

[0045] An all-in-one machine for wafer performance testing and sampling, including a system control cabinet 1, the bottom of which is symmetrically equipped with load-bearing leveling support feet 2 and universal Fuma wheel 3, and the top of the system control cabinet 1 is equipped with a wafer placement Mechanism, position adjustment mechanism and performance testing and sampling integration mechanism;

[0046] The system control cabinet 1 installs the control system hardware, and runs the software control system to realize the combined effect of wafer testing and spotting. By setting the universal Fuma wheel 3, any mobile device can be realized. According to the display of the universal level 404, the machine Adjust to the best balance angle to ensure the accuracy of the machine.

[0047] The wafer placement mechanism is arranged above the system control cabinet 1. The wafer placement mechanism is used to place the wafer when performing performance testing and spotting of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com