Movable centre grinding device and grinding method thereof

A kind of top and lathe technology, applied in the direction of grinding drive device, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of unable to meet the repair grinding, the accuracy error of the moving center axis, and eliminate the moving center mandrel. Axis offset, elimination of precision errors, easy installation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

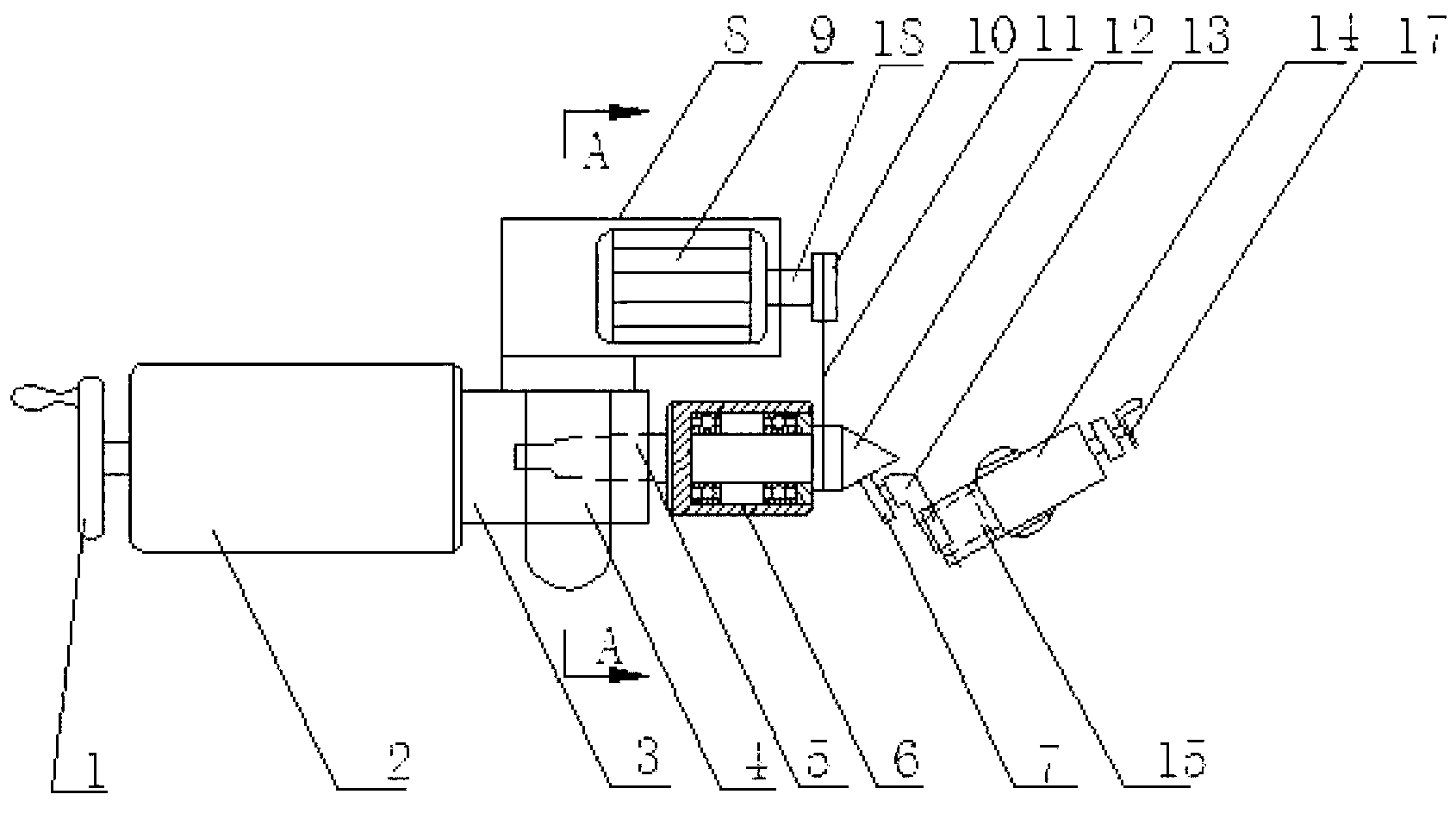

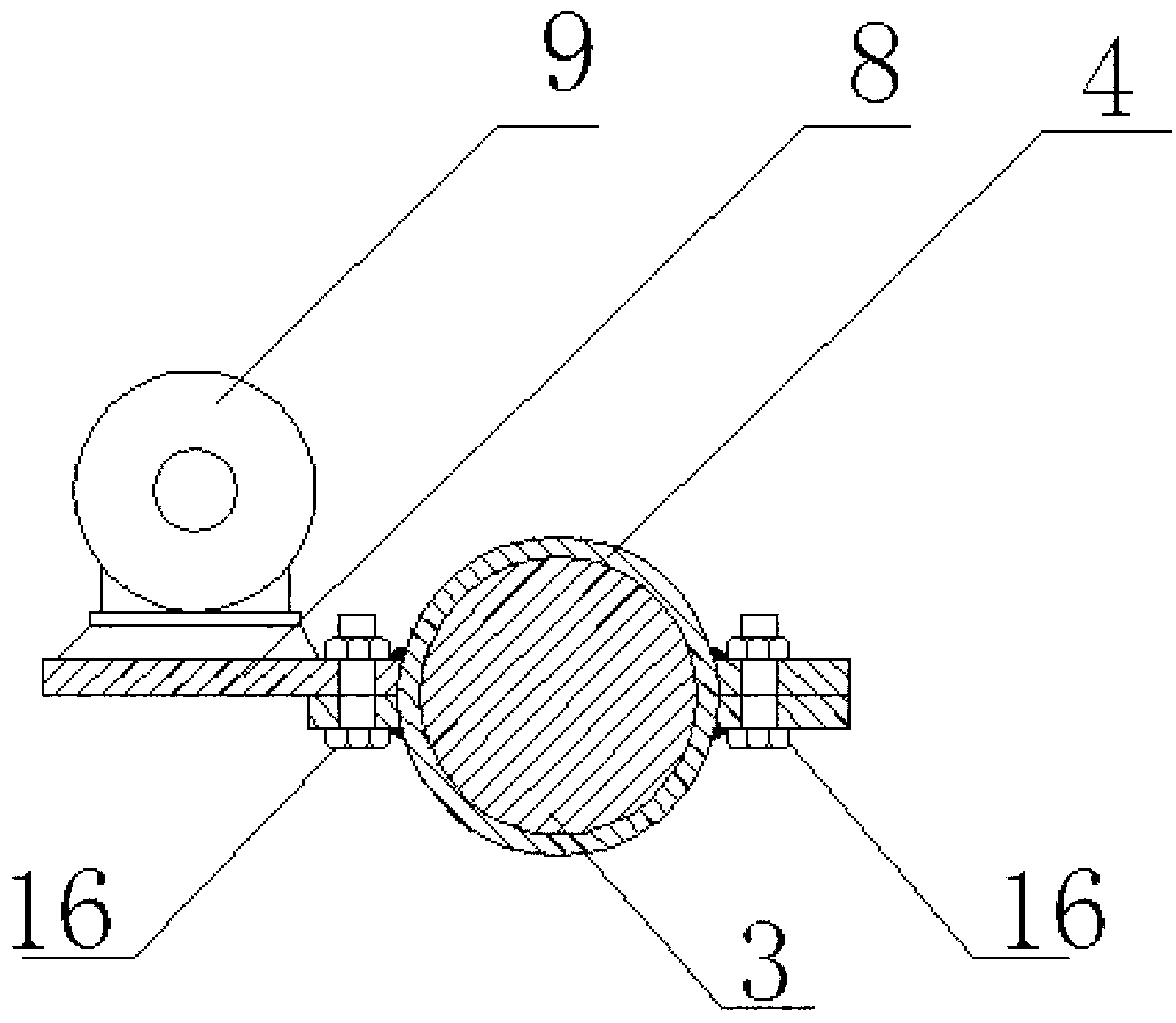

[0019] In order to overcome the problem that the existing active center grinding device cannot meet the requirements of repairing grinding and using the active center grinding with the same rotation reference, resulting in the existence of axis accuracy errors in the active center after grinding, this embodiment provides a figure 1 The movable top grinding device shown includes a lathe tailstock telescopic shaft 3 with an axial inner tapered hole at the end, a micro grinder 13 installed on the tool rest 15 of the small carriage 14 of the lathe (its end It is provided with a grinding wheel 7) and a stepless speed regulation motor 9 for driving the movable top mandrel 12 to rotate, and the stepless speed regulation motor 9 is installed on a horizontal support platform 8, which passes through two semicircle open sides The steel sleeve 4 clamps on the outer wall of the telescopic shaft 3 of the lathe tailstock, and the horizontal support platform 8 is welded on the steel sleeve 4 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com